A kind of DHA algae oil microcapsule powder with high oil loading and its preparation process

A technology of microcapsule powder and algae oil, which is applied in food preparation, food shaping, food science, etc., and can solve problems such as being easily oxidized and deteriorating, affecting the physiological function of DHA, and producing negative effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

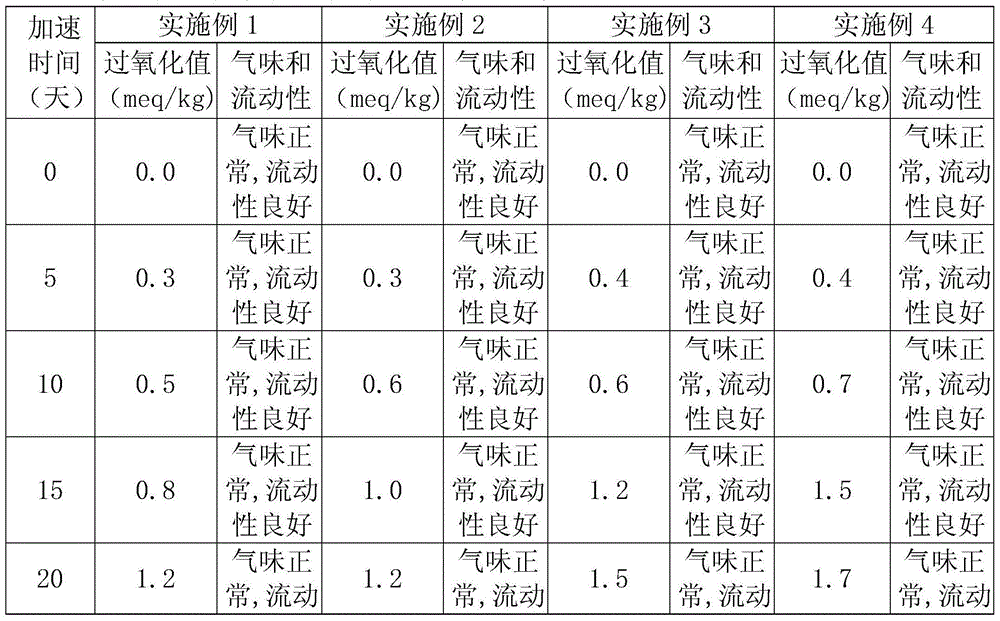

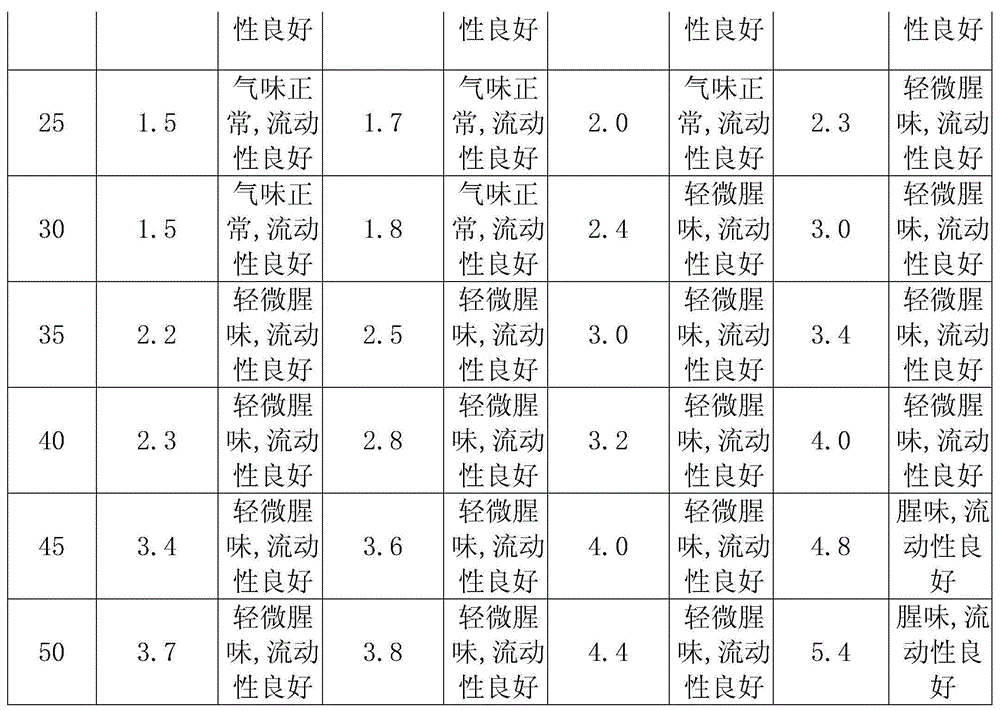

Embodiment 1

[0017] Add the outer wall material and emulsifier (whey protein isolate, egg white protein powder, gum arabic, xanthan gum, glucose, maltodextrin, sodium caseinate, monoglyceride, sucrose fatty acid ester, mass The proportions are 10%, 5%, 5%, 0.5%, 10%, 32.8%, 1.0%, 0.1%, 0.1%), add pure water, heat and mix at 50-60°C, and obtain pre-emulsification through high-speed emulsification Then add core material and antioxidant (DHA algae oil, VE, VC palmitate, iso-VC sodium, lecithin, citric acid, the mass ratio of DHA algae oil is 35.0%, and the DHA content in DHA algae oil is 40.0% , the mass ratio of antioxidant is 0.5%), and the emulsification and shearing are continued. Then, it was homogenized twice by a high-pressure homogenizer 40.0MP to obtain a milky white emulsion. Then the emulsified liquid is spray-dried by a spray-drying tower to obtain DHA algae oil microcapsule powder, and the spray-drying air inlet temperature is 180-210 DEG C, and the air outlet temperature is 80-...

Embodiment 2

[0020] Add the outer wall material and emulsifier (whey protein isolate, egg white protein powder, gum arabic, carrageenan, linseed gum, palatinose, maltodextrin, sodium caseinate, monoglyceride, Sucrose fatty acid ester, the mass ratio is 15%, 5%, 5%, 0.5%, 0.5%, 10%, 22.2%, 1.0%, 0.15%, 0.15%), add pure water, heat at 50-60°C Mix evenly, obtain pre-emulsion by high-speed emulsification, then add core material and antioxidant (DHA algae oil, VE, VC palmitate, iso-VC sodium, lecithin, citric acid, DHA algae oil mass ratio is 40.0% , the DHA content in the DHA algae oil is 50.0%, and the mass ratio of antioxidants is 0.5%), and the emulsification and shearing are continued. Then homogenize once by a high-pressure homogenizer 50.0MP to obtain a milky white emulsion. Then the emulsified liquid is spray-dried by a spray-drying tower to obtain DHA algae oil microcapsule powder, and the spray-drying air inlet temperature is 180-210 DEG C, and the air outlet temperature is 80-100 DE...

Embodiment 3

[0023] Add the outer wall material and emulsifier (whey protein isolate, egg white protein powder, gum arabic, carrageenan, linseed gum, lactose, maltodextrin, sodium caseinate, monoglyceride, sucrose fatty acid) into the emulsification tank ester, the mass ratio is respectively 15%, 5%, 5%, 0.5%, 0.5%, 10%, 22.2%, 1.0%, 0.15%, 0.15%), add pure water, heat and mix evenly at 50-60°C, Obtain pre-emulsion through high-speed emulsification, then add core material and antioxidant (DHA algae oil, VE, VC palmitate, iso-VC sodium, lecithin, citric acid, DHA algae oil mass ratio is 40.0%, DHA algae oil The DHA content in the medium is 60.0%, and the mass proportion of antioxidant is 0.5%), and the emulsification and shearing are continued. Then homogenize once by a high-pressure homogenizer 50.0MP to obtain a milky white emulsion. Then the emulsified liquid is spray-dried by a spray-drying tower to obtain DHA algae oil microcapsule powder, and the spray-drying air inlet temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com