Porous foamed ceramic loaded nanometer zero-valent iron composite and preparation method thereof

A nano-zero-valent iron and ceramic loading technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of easy deactivation, difficult recycling and reuse, and easy agglomeration of magnetic properties, etc. problem, to improve the effect of being easily oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Pretreatment of Precursor

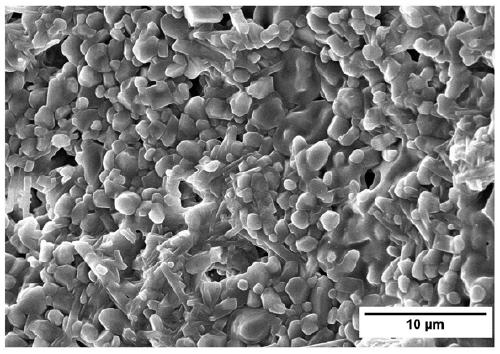

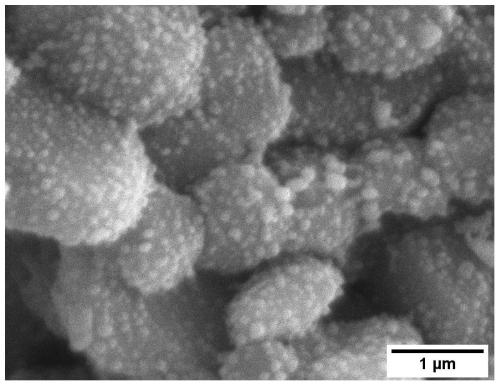

[0032] 9.92g of FeSO 4 ·7H 2 O was dissolved in 100mL ethanol water solution (alcohol-water ratio: 2:3), stirred to dissolve, then added 5g of polyethylene glycol PEG-4000 as a dispersant, and at the same time added foam ceramics and then magnetically stirred at a certain speed for 30min to mix evenly. 100mL of NaBH with a concentration of 1mol / L 4 The solution was added dropwise to the solid-liquid mixture at a rate of 3.3 ml / min, and magnetic stirring was continued for 60 minutes after the addition. The dispersion mixture was sonicated for 10 minutes every 20 minutes of stirring.

[0033] Step 2: Hydrothermal Treatment

[0034] Put the solid-liquid mixture containing foam ceramics obtained in step 1 into a 250ml autoclave, control its filling degree within an appropriate range, then put it into a drying oven, and set the hydrothermal treatment temperature to 150°C, and the holding time After 5 hours, after starting to heat up, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com