Aqueous woodenware statin topcoat and preparation method thereof

A water-based color concentrate and water-based technology, applied in the direction of coating, etc., can solve the problems of long construction interval, low concentration of water-based color concentrate, and reduced construction efficiency, and achieve the effect of improving construction efficiency, fast drying speed, and short construction interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of water-based wood surface repair paint of the present invention, water-based wood surface repair paint is made up of following components by mass percentage:

[0030] Water-Based Color Correcting Base 97%,

[0031] High concentration water-based color essence 3%.

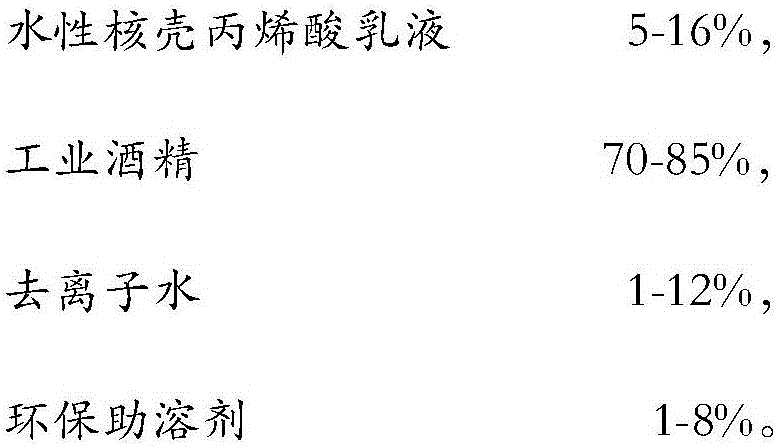

[0032] The water-based color correction base material is composed of the following components by weight percentage:

[0033]

[0034] Described high-concentration water-based color essence is made up of following components by weight percentage:

[0035] High concentration water-based yellow essence 40%,

[0036] High concentration water-based red essence 50%,

[0037] High concentration water-based black essence 10%.

[0038] The water-based core-shell acrylic emulsion is the JF1015 water-based acrylic resin dispersion of Zibo Jiafeng Chemical Industry.

[0039] The environmental protection co-solvent is propylene glycol butyl ether.

[0040] The high-concentration water-based color essence...

Embodiment 2

[0046] The difference between embodiment 2 and embodiment 1 is:

[0047] A kind of water-based wood surface repair paint of the present invention, water-based wood surface repair paint is made up of following components by mass percentage:

[0048] Water-Based Color Correcting Base 85%,

[0049] High concentration water-based color essence 15%.

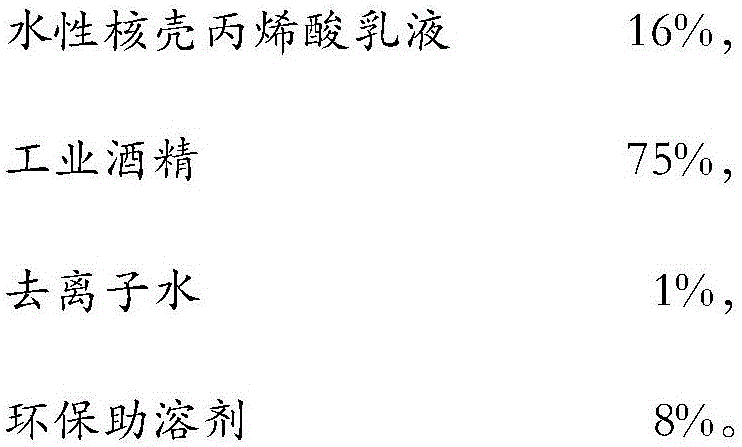

[0050] The water-based color correction base material is composed of the following components by weight percentage:

[0051]

[0052] Described high-concentration water-based color essence is made up of following components by weight percentage:

[0053] High concentration water-based yellow essence 45%,

[0054] High-concentration water-based red essence 48%,

[0055] High concentration water-based black essence 12%.

[0056] The aqueous core-shell acrylic emulsion is JF2025 high-solid aqueous styrene-acrylic resin dispersion produced by Zibo Jiafeng Chemical Industry.

[0057] The environmental protection co-solvent is prop...

Embodiment 3

[0063] The difference between embodiment 3 and embodiment 1 is:

[0064] A kind of water-based wood surface repair paint of the present invention, water-based wood surface repair paint is made up of following components by mass percentage:

[0065] Water-Based Color Correcting Base 90%,

[0066] High concentration water-based color essence 10%.

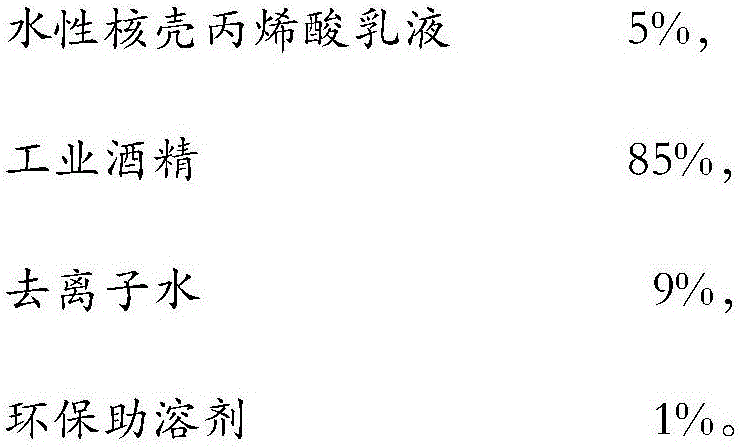

[0067] The water-based color correction base material is composed of the following components by weight percentage:

[0068]

[0069] Described high-concentration water-based color essence is made up of following components by weight percentage:

[0070] High concentration water-based yellow essence 50%,

[0071] High-concentration water-based red essence 40%,

[0072] High concentration water-based black essence 10%.

[0073] The water-based core-shell acrylic emulsion is a combination of two types of JF1015 water-based acrylic resin dispersion and JF2025 high-solid water-based styrene-acrylic resin dispersion produced by Zibo ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com