Foaming agent for drainage and gas recovery containing diaryl sulfonate

A technology of aliphatic diaryl sulfonate and aryl sulfonate, which is applied in the direction of mining fluid, earthwork drilling, and drilling composition, and can solve the problem of drainage and gas recovery that cannot meet the needs of high-temperature and high-salinity gas wells , Poor thermal stability of the foaming agent and other issues, to achieve the effect of strong foaming performance and good foam stabilizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

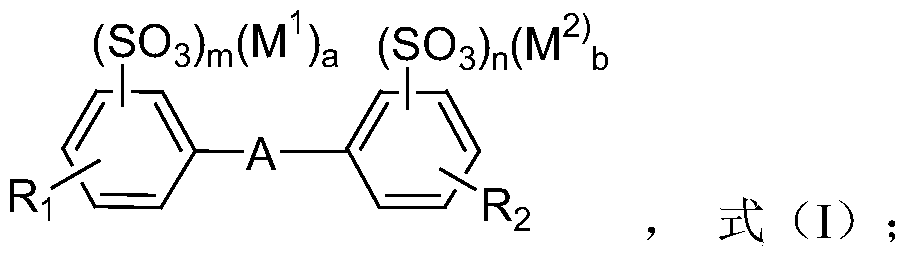

Method used

Image

Examples

Embodiment 1

[0037] In terms of mass percent, get sodium dodecyl diphenyl ether sulfonate X (wt%), lauric acid amidopropyl betaine Y (wt%), Southwest oil field formation simulation water 1, stir 30 minutes, obtain required Foaming agent. The ion content of formation simulation water 1 in Southwest Oilfield is shown in Table 1. Under the condition of 75°C water bath, the foaming volume and foam half-life of the foam discharge agent were measured by Ross-Miles method, and the results are shown in Table 2.

[0038] Table 1

[0039] name Na +

Mg 2+

Ca 2+

Cl -

total salinity Content (mg / L) 8109 50 926 13915 23000

[0040] Table 2

[0041] X (wt%) 0.03 0.06 0.09 0.12 Y (wt%) 0.17 0.14 0.11 0.08 Bubble volume (mL) 410 420 400 390 Foam half-life (s) 800 1560 1250 700

Embodiment 2

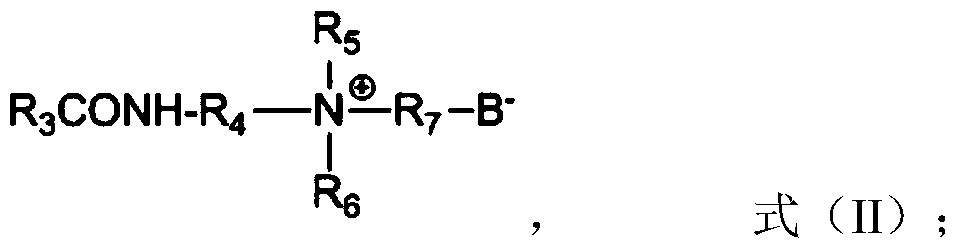

[0043] Take the foam discharge agent in [Example 1] and put it into a pressure bomb, put it into an oven, and take it out after aging at 100°C for 30 days. Under the condition of a water bath at 75°C, use the Ross-Miles method to measure the foam discharge agent after aging. The foam volume and foam half-life are shown in Table 3.

[0044] table 3

[0045] X (wt%) 0.03 0.06 0.09 0.12 Y (wt%) 0.17 0.14 0.11 0.08 Bubble volume (mL) 400 410 400 380 Foam half-life (s) 720 1340 1190 620

Embodiment 3

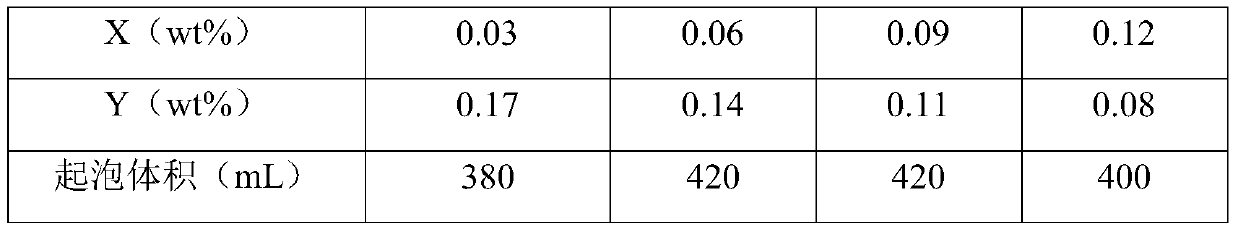

[0047] In terms of mass percentage, get sodium dodecyl diphenyl ether sulfonate X (wt%), lauryl amidopropyl betaine Y (wt%), Southwest Oilfield formation simulation water 2, stir for 30 minutes, obtain required foam Discharge agent. The ion content of formation simulation water 2 in Southwest Oilfield is shown in Table 4. Under the condition of 75°C water bath, the foam volume and foam half-life of the foam discharge agent were measured by Ross-Miles method, and the results are shown in Table 5.

[0048] Table 4

[0049] name Na +

Mg 2+

Ca 2+

Cl -

total salinity Content (mg / L) 58310 500 3500 97690 160000

[0050] table 5

[0051] X (wt%) 0.03 0.06 0.09 0.12 Y (wt%) 0.17 0.14 0.11 0.08 Bubble volume (mL) 470 420 410 400 Foam half-life (s) 800 1056 730 640

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com