Gas well foaming agent and its preparation method and application

A technology of foaming agent and gas well, which is applied in the fields of anti-acid gas well foaming agent, temperature resistance and salt resistance, which can solve the problems of poor foam stability, long half-life, large liquid carrying capacity, etc. Strong bubble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

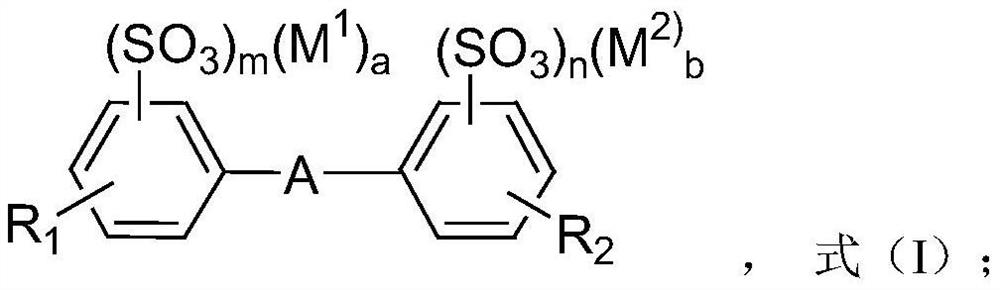

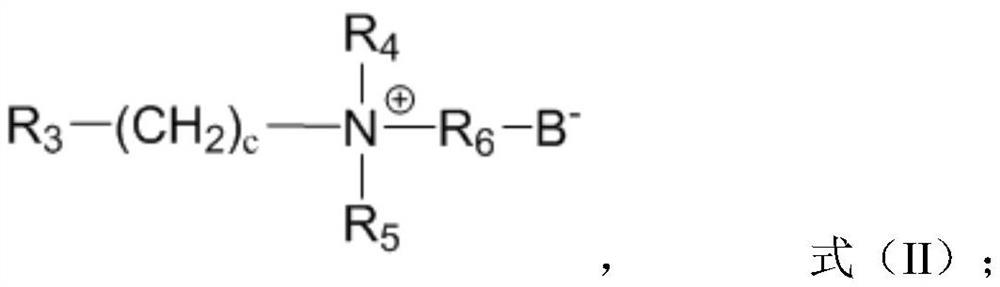

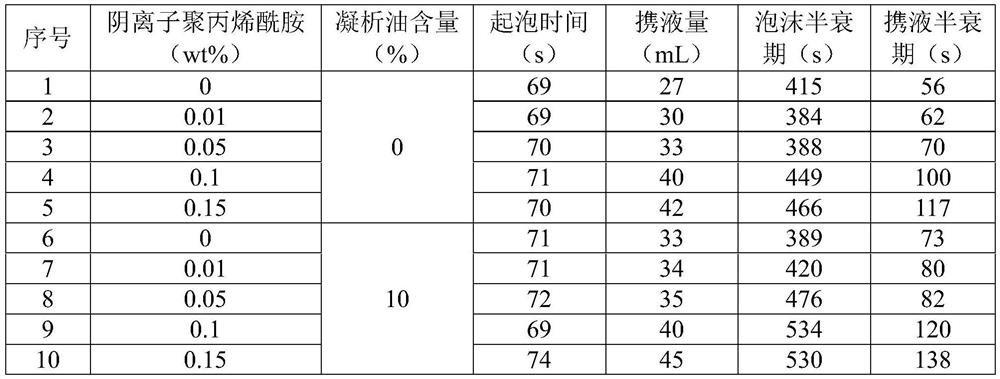

[0041] In terms of mass percentage, 0.06wt% sodium dodecyl diphenyl ether sulfonate (R 1 , R 2 =C 12 ;A=O;M 1 , M 2 =Na + ), 0.14wt% cocamidopropyl betaine (R 3 =R'CONH-;R'=C 8 ~C 18 , R 4 , R 5 =CH 3 , R 6 =-CH 2 -, B is COO - , c=3) and a certain amount of anionic polyacrylamide X (wt%) were dissolved in Southwest Oilfield Formation Simulated Water 1 and stirred for 30 minutes to obtain the required foaming agent. The ion content of formation simulation water 1 in Southwest Oilfield is shown in Table 1. Under the condition of a water bath at 75°C, the foaming time, liquid carrying capacity, foam half-life and liquid carrying half-life of the foam discharge agent were measured with a foam scanning analyzer (FOAMSCAN). The results are shown in Table 2.

[0042] Table 1

[0043] name Na +

Mg 2+

Ca 2+

Cl -

total salinity pH value Content (mg / L) 8109 50 926 13915 23000 4.5

[0044] Table 2

[0045]

Embodiment 2

[0047] Take the foam discharge agent in [Example 1] and put it into a pressure bomb, put it into an oven, age at 150°C for 15 days, take it out, and measure the foam discharge agent’s performance with a foam scanning analyzer (FOAMSCAN) under the condition of a 75°C water bath. The results of foaming time, liquid carrying capacity, foam half-life and liquid carrying half-life are shown in Table 3.

[0048] table 3

[0049]

Embodiment 3

[0051] In terms of mass percentage, get 0.02wt% sodium dodecyl diphenyl ether sulfonate (R 1 , R 2 =C 12 ;A is O;M 1 , M 2 for Na + ), 0.18wt% cocamidopropyl betaine and a certain amount of anionic polyacrylamide were dissolved in the Southwest oilfield formation simulated water 2 and stirred for 30 minutes to obtain the required foaming agent. The ion content of formation simulation water 2 in Southwest Oilfield is shown in Table 4. Under the condition of a water bath at 75°C, the foaming time, liquid carrying capacity, foam half-life and liquid carrying half-life of the foam discharge agent were measured with a foam scanning analyzer (FOAMSCAN). The results are shown in Table 5.

[0052] Table 4

[0053] name Na +

Mg 2+

Ca 2+

Cl -

total salinity pH value Content (mg / L) 58310 500 3500 97690 160000 3.6

[0054] table 5

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com