Industrial robot joint speed reducer lubricating grease and preparation method thereof

An industrial robot and grease technology, applied in the field of grease, can solve the problem of fretting wear grease cycle, etc., and achieve the effect of improving service life, reducing anti-wear performance, and reducing anti-fretting wear performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

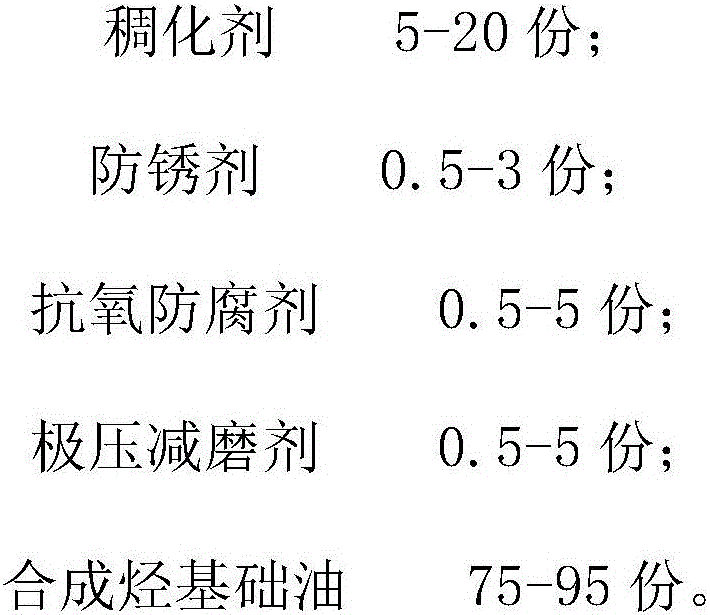

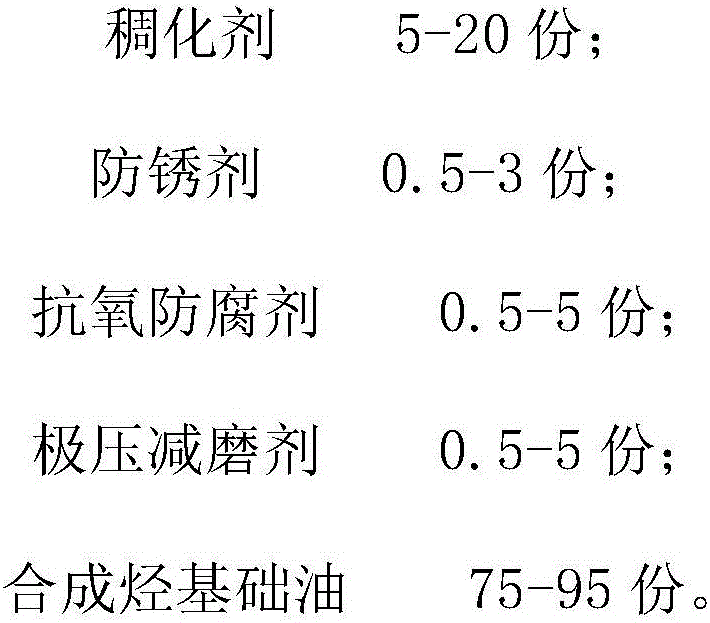

[0020] Prepare 100Kg of industrial robot joint reducer lubricating grease, which is composed of the following components by weight: thickener 10Kg; rust inhibitor 2Kg; antioxidant anticorrosion agent 5Kg; extreme pressure antifriction agent 5Kg; synthetic hydrocarbon base oil 78Kg . The thickener is lithium stearate; the rust inhibitor is calcium petroleum sulfonate; phenyl esters.

[0021] The above-mentioned industrial robot joint reducer grease is prepared by the following preparation method:

[0022] a. Add the thickener to the synthetic hydrocarbon base oil, stir while heating, heat to 100°C, heat and stir for 2 hours, completely dissolve the thickener in the base oil to obtain a mixed oil, and then cool to 65°C;

[0023] b. Add the antirust agent, anti-oxidation preservative, and extreme pressure antifriction agent into the mixed oil respectively while stirring, and then stir for 1 hour;

[0024] c. After the temperature of the mixed oil obtained in step b is lowered ...

Embodiment 2

[0026] Prepare 100Kg of industrial robot joint reducer lubricating grease, which is composed of the following components by weight: thickener 5Kg; rust inhibitor 1Kg; antioxidant anticorrosion agent 1Kg; extreme pressure antifriction agent 3Kg; synthetic hydrocarbon base oil 90Kg . The thickener is barium stearate; the antirust agent is lanolin; the anti-oxidation anticorrosion agent is diphenylamine, and the extreme pressure antifriction agent is polytetrafluoroethylene.

[0027] The above-mentioned industrial robot joint reducer grease is prepared by the following preparation method:

[0028] a. Add the thickener to the synthetic hydrocarbon base oil, stir while heating, heat to 150°C, heat and stir for 5 hours, completely dissolve the thickener in the base oil to obtain a mixed oil, and then cool to 65°C;

[0029] b. Add the antirust agent, anti-oxidation preservative, and extreme pressure antifriction agent into the mixed oil respectively while stirring, and then stir for...

Embodiment 3

[0032] Prepare 100Kg of industrial robot joint reducer lubricating grease, which consists of the following components by weight: 15Kg thickener; 0.5Kg rust inhibitor; 2Kg anti-oxidant anticorrosion agent; 0.5Kg extreme pressure antifriction agent; synthetic hydrocarbon base Oil 82Kg. The thickener is lithium potassium oleate; the rust inhibitor is dodecenylsuccinic acid; the anti-oxidation anticorrosion agent is phenylenediamine, and the extreme pressure antifriction agent is molybdenum carbamate.

[0033] The above-mentioned industrial robot joint reducer grease is prepared by the following preparation method:

[0034] a. Add the thickener to the synthetic hydrocarbon base oil, stir while heating, heat to 150°C, heat and stir for 5 hours, completely dissolve the thickener in the base oil to obtain a mixed oil, and then cool to 65°C;

[0035] b. Add the antirust agent, anti-oxidation preservative, and extreme pressure antifriction agent into the mixed oil respectively while s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com