Cam type driving weft needle device

A cam type and weft needle technology, which is applied in the direction of textile, textile, papermaking, loom, etc., can solve the problems of large movement range, poor driving effect, and loose weaving, etc., and achieves compact cam structure, small inertial mass, and moment of inertia small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

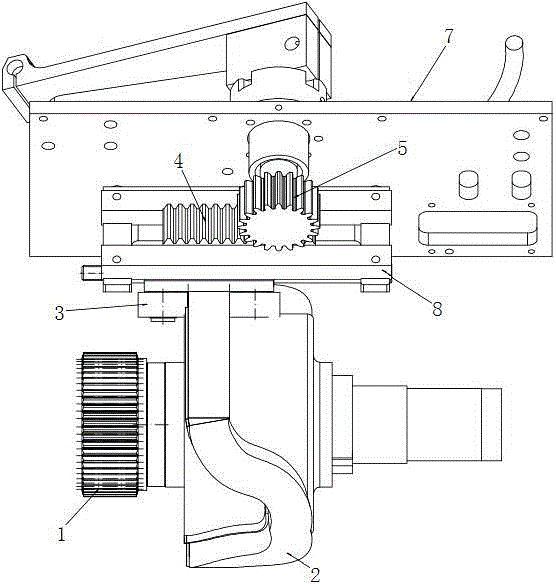

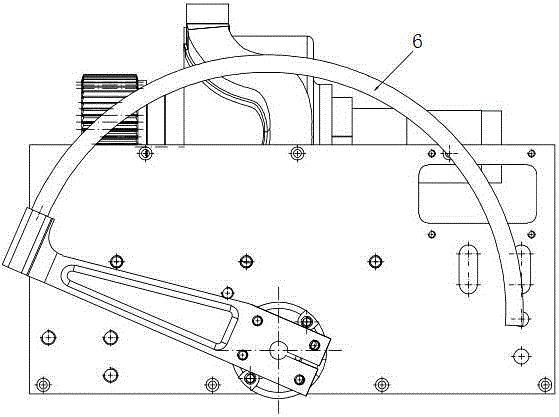

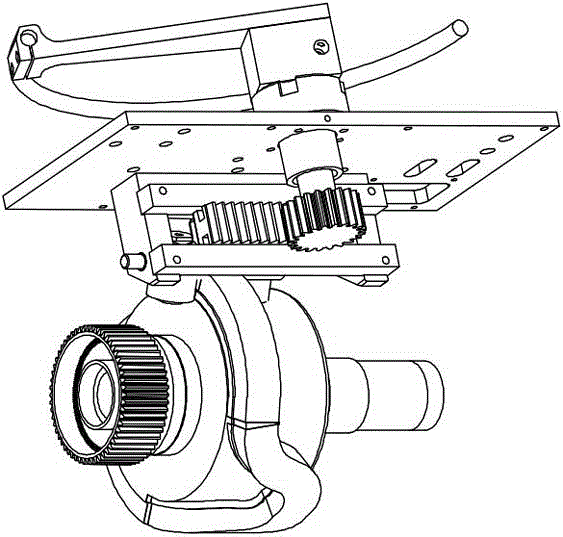

[0021] refer to Figure 1 to Figure 3 As shown, a cam-driven weft needle device includes a main shaft gear 1, a cam 2 coaxially arranged with the main shaft gear 1, and a rack support 3 matched with the working surface of the cam 2, and the tooth The bar support 3 is fixedly connected with a rack 4, the tooth surface of the rack 4 is provided with a countershaft gear 5 matched with it, the shaft of the countershaft gear 5 is provided with a weft needle 6, and the cam 2 is provided with It includes at least one curved portion 21 for pushing the rack support 3 to perform reciprocating linear motion.

[0022] The shaft of the countershaft gear 5 is arranged on a connecting cover 7 through corresponding bearings, and the weft needle 6 and the countershaft gear 5 are respectively arranged on both sides of the connecting cover 7 .

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com