Composite skeleton structure slide plate for bridge support

A skeleton structure, bridge bearing technology, applied in bridges, bridge materials, bridge construction and other directions, can solve the problems of single friction coefficient of friction pair material, can not meet the friction coefficient, friction coefficient is not adjustable, etc., to achieve good wear resistance, High carrying capacity and the effect of meeting the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

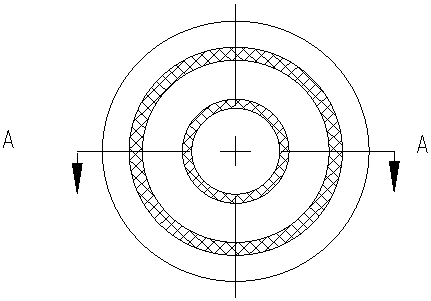

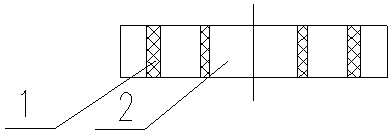

[0035] Such as figure 1 , 2 As shown, a composite skeleton structure slide plate for bridge bearings is composed of a skeleton support 1 and a filling matrix 2 . Skeleton support 1 is circular, with the center of the filled matrix as the center, and multiple sets can be set. Its material is filled polytetrafluoroethylene, and its raw material composition and mass percentage are: polytetrafluoroethylene 65%, carbon fiber 25%, two Molybdenum sulfide 2%, graphite 8%. The filling matrix material 2 is filled around the skeleton support material 1, and the material is polytetrafluoroethylene, and its raw material composition and mass percentage are: polytetrafluoroethylene 100%.

[0036] Weigh each component, put them into a high-speed mixer and mix evenly; use compression molding, firstly use a circular feeding tool to add a skeleton support 1 to the mold, add a filling matrix 2 to the vacant position, scrape, remove the feeding tool, and combine Die, mold on a press, and releas...

Embodiment 2

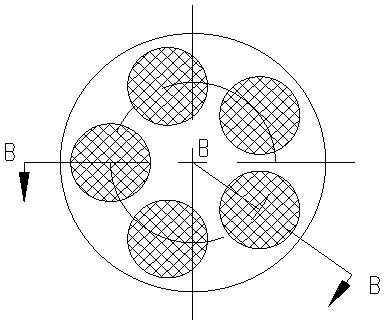

[0039] Such as image 3 , 4 As shown, a composite skeleton structure slide plate for bridge bearings is composed of a skeleton support 1 and a filling matrix 2 . Skeleton support 1 is circular, made of modified ultra-high molecular weight polyethylene, and its raw material composition and mass percentage are: ultra-high molecular weight polyethylene 75%, carbon fiber 18%, molybdenum disulfide 1%, silicon carbide 1%, glass micro Beads 5%. The filling matrix 2 is filled around the skeleton support 1, and the material is modified ultra-high molecular weight polyethylene, and its raw material composition and mass percentage are: ultra-high molecular weight polyethylene 92%, polytetrafluoroethylene 5%, and molybdenum disulfide 3%.

[0040] Weigh each component, put them into a high-speed mixer and mix them evenly; adopt the simultaneous method of molding and sintering to form, firstly add a skeleton support 1 to the mold with a circular feeding tool, add a filling matrix material...

Embodiment 3

[0043] Such as Figure 5 , 6As shown, a composite skeleton structure slide plate for bridge bearings is composed of skeleton support material 1 and filling matrix material 2 . The skeleton support material 1 is honeycomb-shaped, and the material is modified polyoxymethylene, and its raw material composition and mass percentage are: polyether ether ketone 75%, glass fiber 20%, molybdenum disulfide 5%. The filler matrix material 2 is filled around the skeleton support material 1, and the material is modified ultra-high molecular weight polyethylene, and its raw material composition and mass percentage are: ultra-high molecular weight polyethylene 90%, nano-alumina 5%, graphite 5%.

[0044] Skeleton support material 1 is prefabricated into a honeycomb shape, placed in the mold, positioned, filled with matrix material 2 in the vacant position, scraped off, clamped, heated and molded on a plastic molding machine at a heating temperature of 230°C, and a holding time of 1 hour. pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com