Soaking load test method of strip-shaped foundation model

A strip foundation and load test technology, which is applied in foundation structure tests, on-site foundation soil surveys, foundation structure engineering, etc., can solve the problem of inability to accurately simulate strip foundations and surface settlement states, and inability to obtain collapsible soil layers Changes in volumetric moisture content, influence of size effect on foundation settlement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

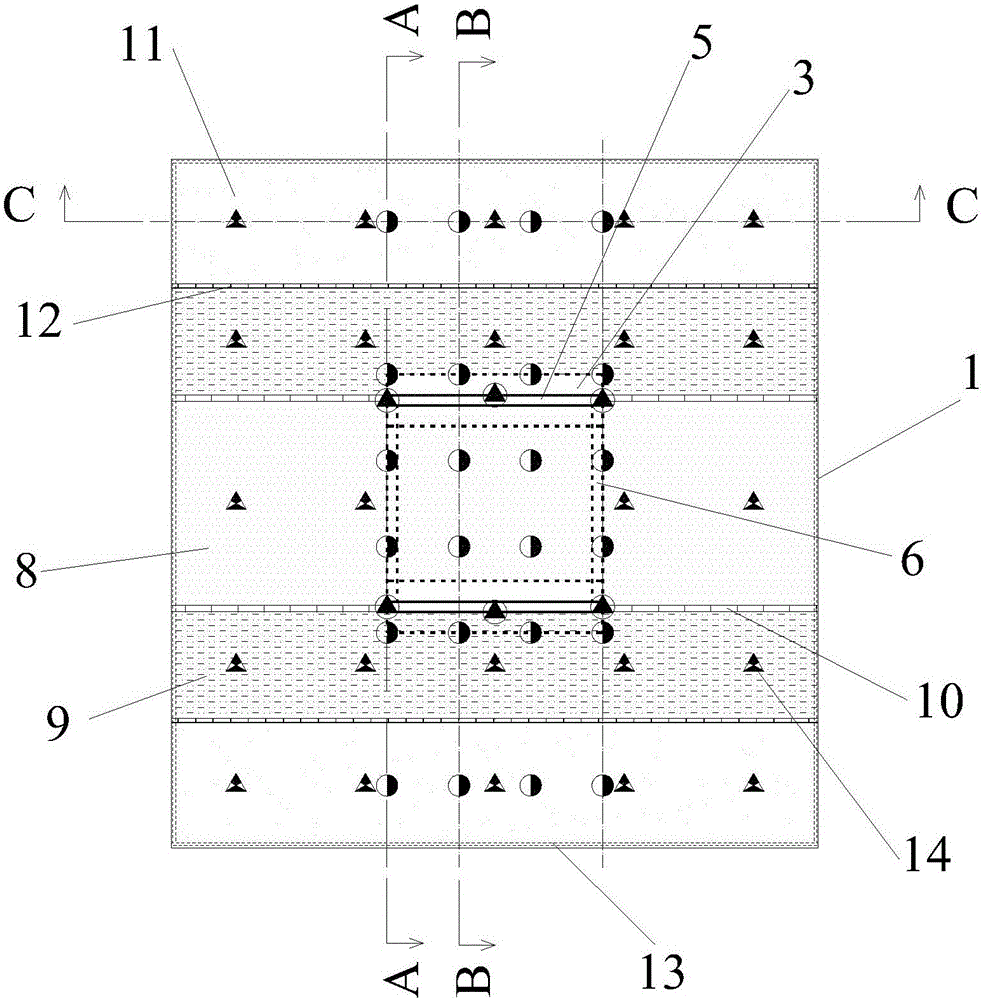

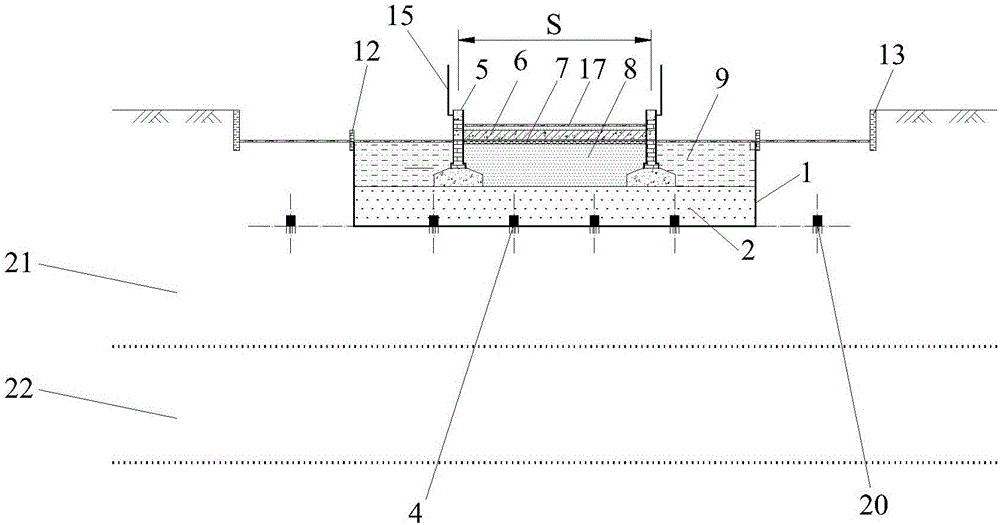

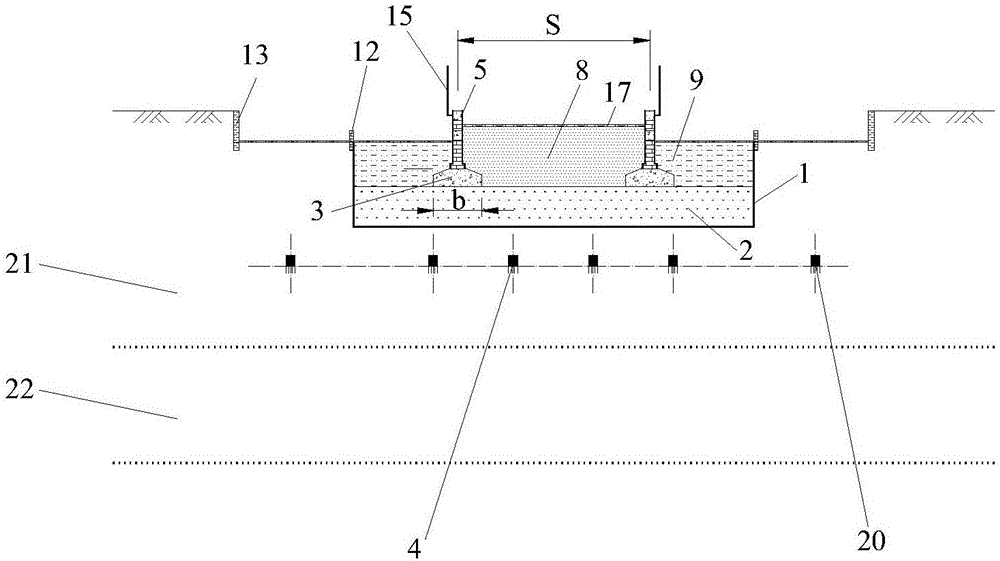

[0060] like figure 1 As shown, the present invention comprises the following steps:

[0061] Step 1, strip foundation model construction: excavate foundation pit 1 from top to bottom, and build strip foundation model 5 in said foundation pit 1, and install monitoring elements in the process of constructing strip foundation model 5, The process is as follows:

[0062] Step 101, excavation of the foundation pit: in the construction strip foundation research site, excavate the foundation pit 1 in advance from top to bottom, wherein the foundation pit 1 is a rectangular foundation pit;

[0063] Step 102, the installation of the first monitoring element: in step 101, a plurality of first soil moisture measuring points are arranged at intervals in the horizontal and vertical directions below the bottom of the foundation pit 1, and a plurality of the first soil moisture The measurement points are respectively installed with the first soil moisture meter 4 to complete the installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com