Fatigue test hydraulic loading device for rigid material

A fatigue test and hydraulic loading technology, which is applied in fluid pressure actuation devices, analysis materials, measurement devices, etc., can solve problems such as low work efficiency and complex systems, and achieve high work reliability, low operating costs, and additional shock loads low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

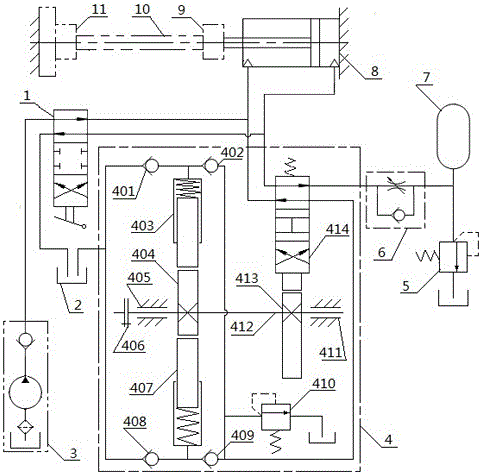

[0020] A hydraulic loading device for a rigid material fatigue test, including a clamping pump station 3, a loading pump station 4, a manual reversing valve 1, an oil cylinder 8, a specimen fixture, an accumulator 7 and an oil storage tank 2 ( figure 1 The middle oil storage tanks 2 are all the same oil storage tank 2, which are only drawn in different parts for the convenience of viewing), the test piece fixtures include fixtures I11 and fixtures II9, and the fixtures I11 are fixed on the machine base. The clamp II9 is connected with the piston rod on the oil cylinder 8, and the cylinder body of the oil cylinder 8 is also fixed on the machine base. The loading pump station 4 includes plunger pump I 403, plunger pump II 407, eccentric wheel 404, cam 413 and reversing valve 414, and the described eccentric wheel 404 and cam 413 are respectively fixed on the same shaft connected to the motor. Above, the plunger pump I 403 and the plunger pump II 407 are respectively driven and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com