Angle-variable subzero-temperature direct shear apparatus for rock and test operation method

A technology of test operation and variable angle, which is applied in the direction of instruments, scientific instruments, strength characteristics, etc., can solve the problems that the fractured rock samples cannot be sheared at any angle, cannot reflect the mechanical properties of fractures, and cannot obtain rock strength, etc., so as to achieve the real monitoring data reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings.

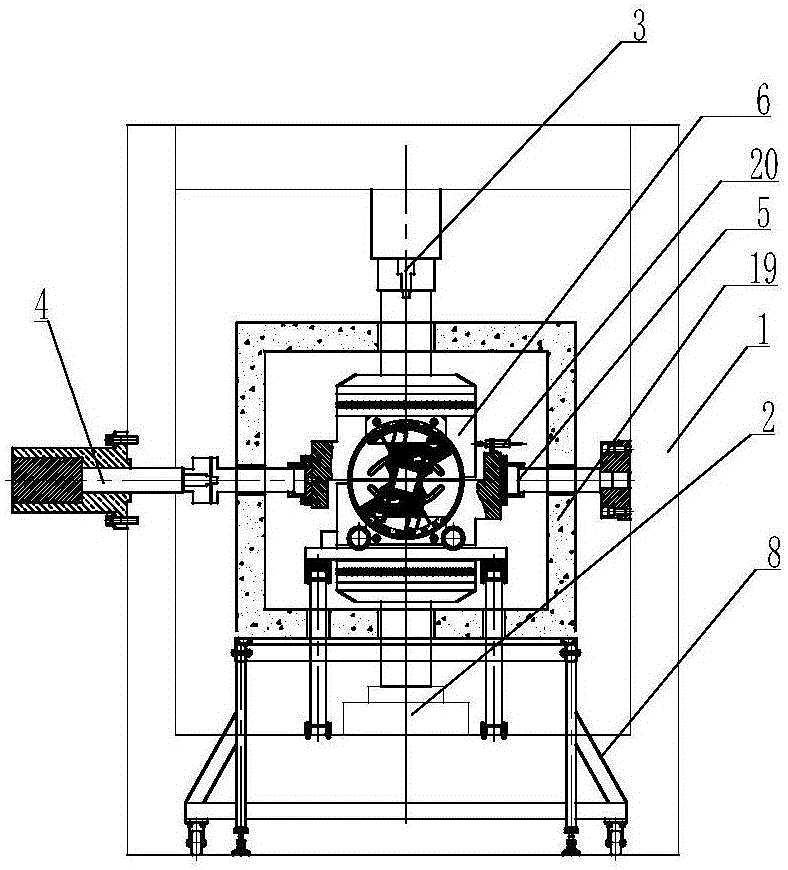

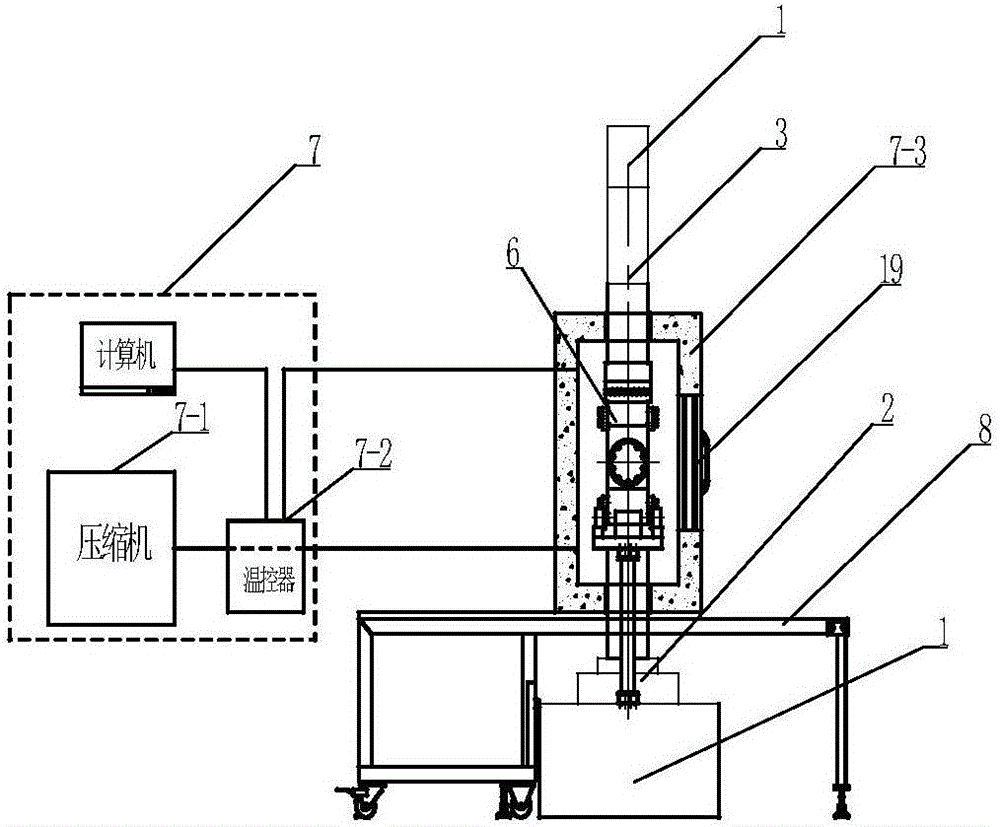

[0048] refer to Figure 1 to Figure 29 , a low-temperature cracked rock direct shear test system, which can measure the negative temperature shear strength of cracked rock samples rotated at different angles under a certain size and a certain normal loading range. The direct shear system is mainly composed of a main frame 1 and a vertical loading mechanism 2 , vertical load supporting mechanism 3, horizontal loading mechanism 4, horizontal load supporting mechanism 5, variable angle shear box 6, temperature control system 7, trolley 8, measurement and control system and computer system. The main frame 1 is composed of a base, a left column, a right column and an upper beam, and each component can be fixed by bolts and welding.

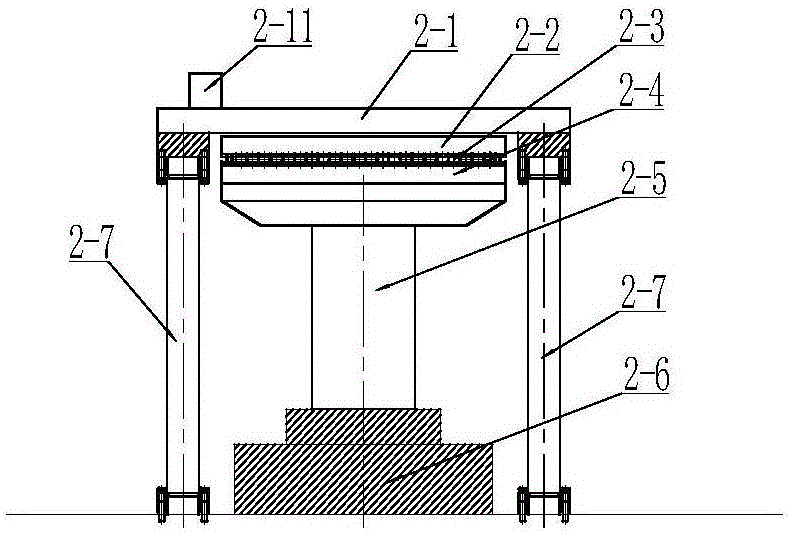

[0049] The vertical loading mechanism 2 is mainly composed of a guide rail frame 2-1, an upper pressure plate 2-2, a vertical pressure bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com