Special automatic test system used for microwave component power supply

A technology for microwave components and power supplies, applied in the field of automated testing of high-power microwave component power supplies, can solve the problems of low test data accuracy, low repetition efficiency, reading errors, etc., and achieve convenient data comparison and historical data query, Guaranteed Accuracy and Reliability, Guaranteed Reliability and Safety Effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

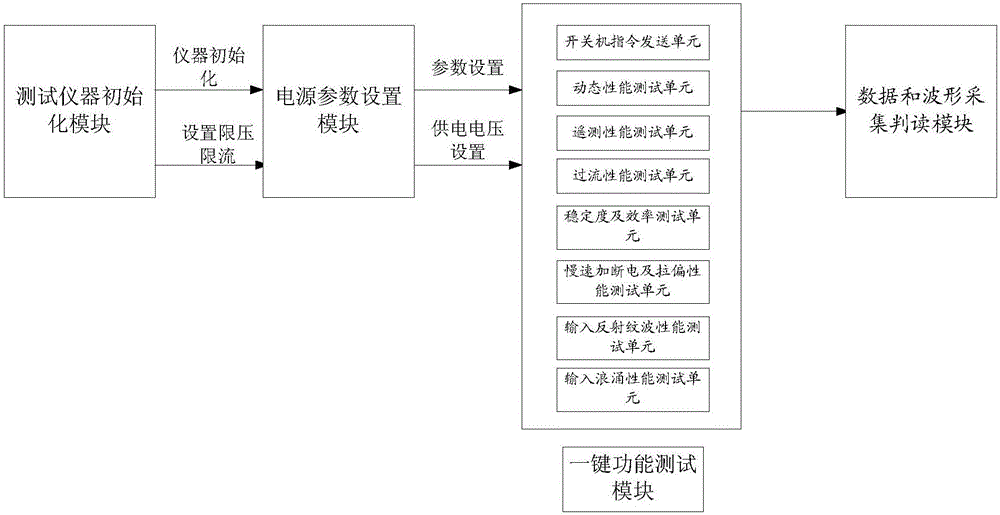

[0026] like figure 1 As shown, the present invention mainly includes a test instrument initialization module, a power parameter setting module, a one-key test function module, and a data and waveform acquisition and interpretation module.

[0027] When testing the microwave component power supply, the computer initializes each test instrument through the test instrument initialization module to ensure that each test instrument maintains a reliable and effective communication connection with the computer. And limit the maximum output voltage and maximum output current of the power supply to ensure that the subsequent power supply voltage is limited within the voltage range that the power supply of the microwave component to be tested can withstand, and prevent the output of the power supply from being treated due to programming errors and human errors. The power supply of the microwave component under test is not damaged, which ensures the reliability of the test.

[0028] Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com