Multi-target optimization method for main bearing of RV speed reducer

A multi-objective optimization and main bearing technology, applied in design optimization/simulation, instruments, special data processing applications, etc., can solve problems that are difficult to explain, have no method to analyze, and have no RV reducer main bearing stiffness and friction torque optimization Cases and other issues to achieve the effect of improving algorithm efficiency and reducing the number of calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

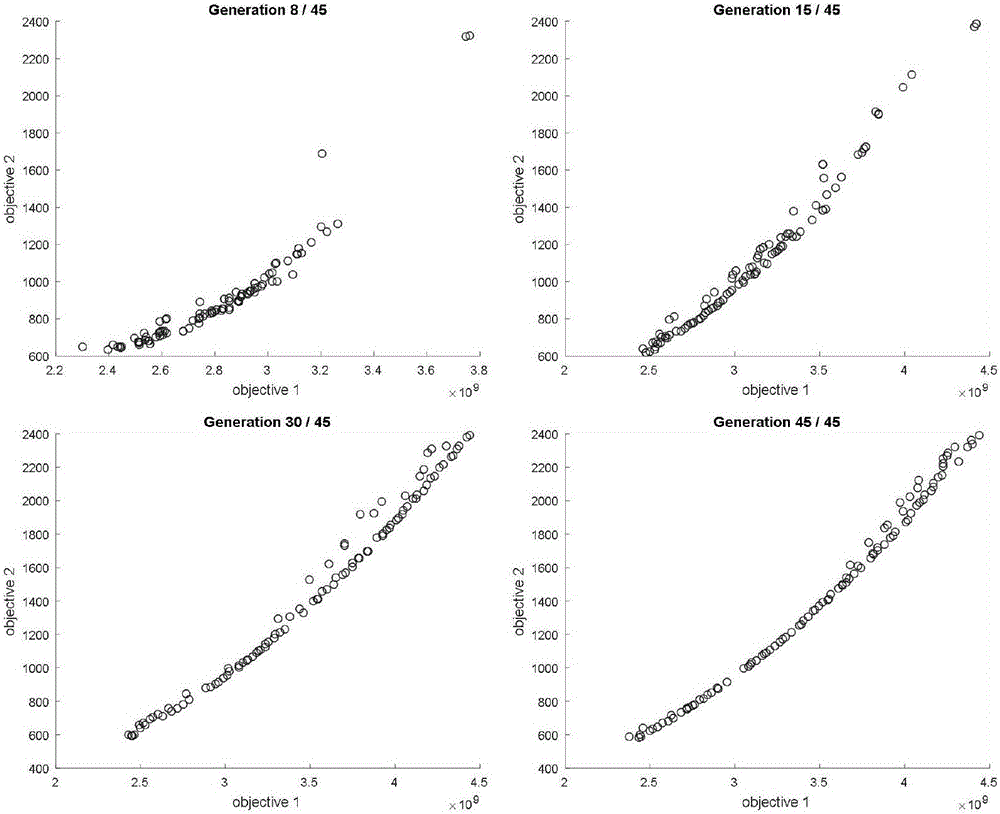

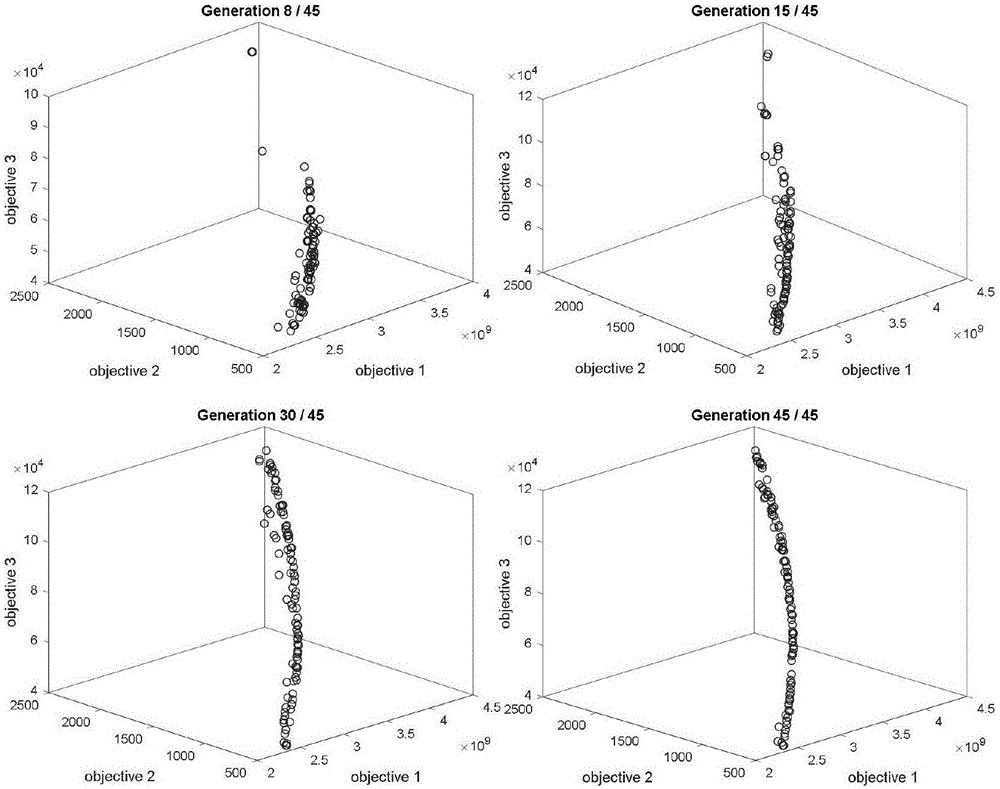

[0032]The model of the main bearing of the RV reducer in the embodiment is H76 / 182, and its main structural parameters are: the number of balls: 51, the ball diameter is 10.319mm, the nominal diameter is 198mm, the curvature coefficients of the inner and outer grooves are: 0.5097, 0.5204, and the initial contact angle About 47 degrees. The angular rigidity, frictional moment and rated axial dynamic load of the main bearing of this type of RV reducer are 3.12e+09N*mm / rad, 1.24e+03N*mm, 7.37e+04N.

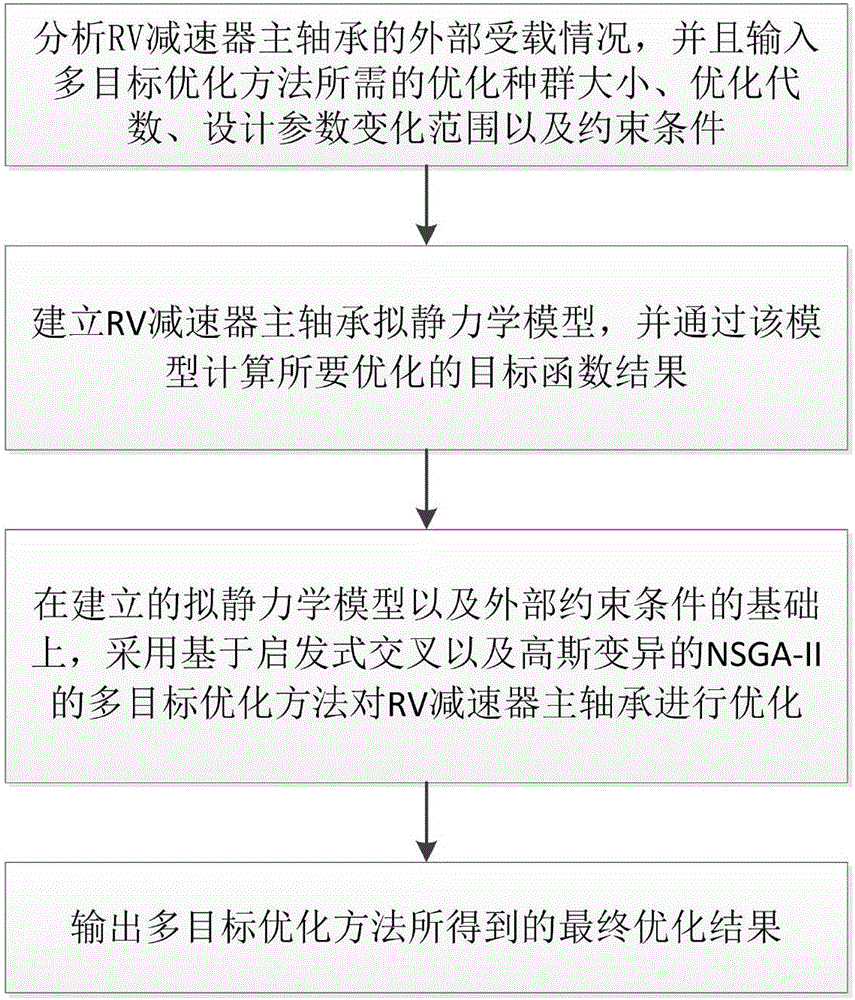

[0033] refer to figure 1 , a multi-objective optimization method for RV reducer main bearings, including the following steps:

[0034] Step 1, analyze the external loading condition of the main bearing, determine the working condition of the main bearing, determine the structural parameters of the main bearing to be optimized, set the upper and lower limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com