Method for improving coercive force of sintered neodymium iron boron magnet

A neodymium-iron-boron and coercivity technology, which is applied in the field of preparation of neodymium-iron-boron magnets, can solve the problems of inability to achieve high remanence Br coercivity, increase the cost of magnets, reduce remanence and the maximum magnetic energy product, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

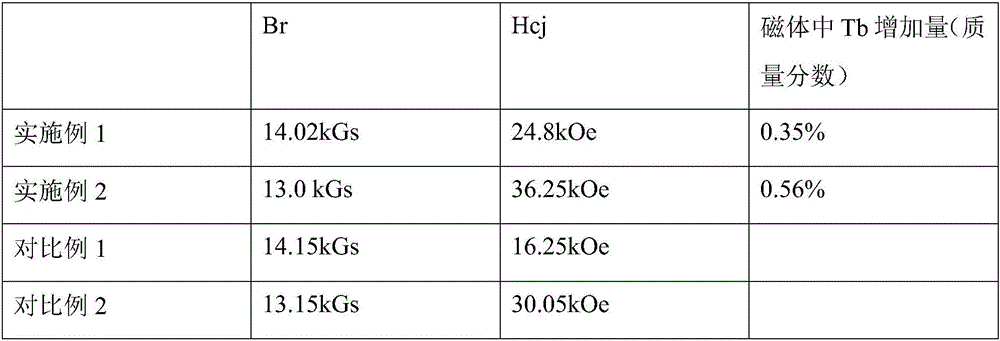

Embodiment 1

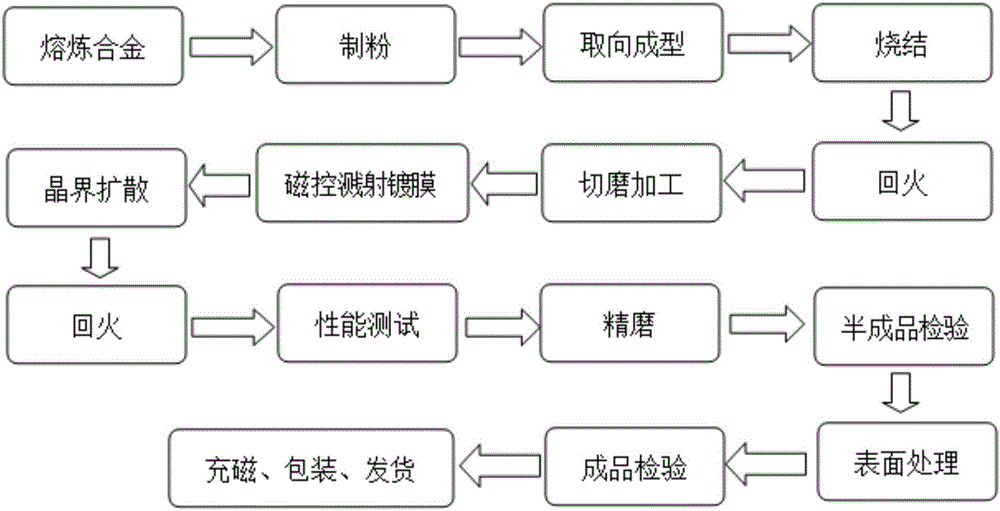

[0042] Such as figure 1 As shown, the method for improving the coercive force of sintered NdFeB magnets described in the present invention comprises the following steps:

[0043] 1) Furnace alloy: sintered NdFeB magnets are made by traditional technology, and the alloy composition includes at least: the total amount of rare earth ΣRe: 29.7% in terms of mass fraction;

[0044] 2) Flour making: use the quick-setting sheet ingot process (Strip Casting) to make sheet ingots, columnar crystal ratio: ≥85%, sheet thickness: 0.1-0.5mm; cast the obtained NdFeB sheet into ingots , after hydrogen crushing and coarse crushing, the average particle size of the coarse powder: 50-200μm, the prepared NdFeB coarse powder is powdered by jet milling, the average particle size of the powder is 2.9μm,

[0045] 3) Orientation molding, sintering, tempering: Orientation magnetic field strength: 1.5T, sintering at 1045°C high temperature sintering, and then tempering at 520°C to make a rough. The ave...

Embodiment 2

[0052] The method for improving the coercive force of a sintered NdFeB magnet according to the present invention comprises the following steps:

[0053] 1) Prepare NdFeB alloy, wherein the raw materials include by mass fraction: the total amount of rare earth ΣRe: 30%, and the content of heavy rare earth Dy / Tb: 8%;

[0054] 2) Using the quick-setting flake ingot process to make flake ingots to obtain NdFeB flake ingots, wherein the proportion of columnar crystals is not less than 85%, and the thickness of the flakes is 0.1-0.5mm;

[0055] 3) The obtained NdFeB flakes are cast into ingots, and the NdFeB coarse powder is obtained by hydrogen crushing and coarse crushing. The average particle size of the coarse powder particles is 50-200 μm, and then the NdFeB powder is obtained by jet milling , the average particle size of the powder is 5μm, and then it is oriented and formed with an orientation magnetic field of 1.8T, then sintered at a high temperature of 1020-1060°C, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com