Lower plate sealing structure of gas-gas heat exchanger

A gas-type heat exchanger and sealing structure technology, applied in the direction of heat exchanger sealing device, heat exchanger shell, heat exchange equipment, etc., can solve the problems of plate corrosion, mixing of cold and hot fluids, easy failure, etc., and achieve production costs. Low, simple sealing structure, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

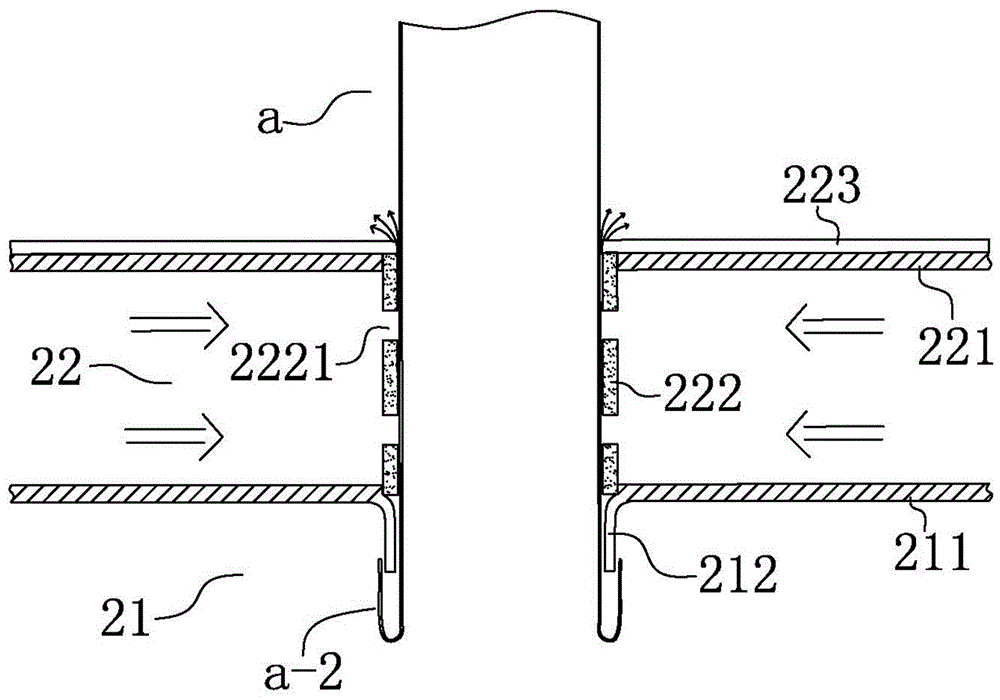

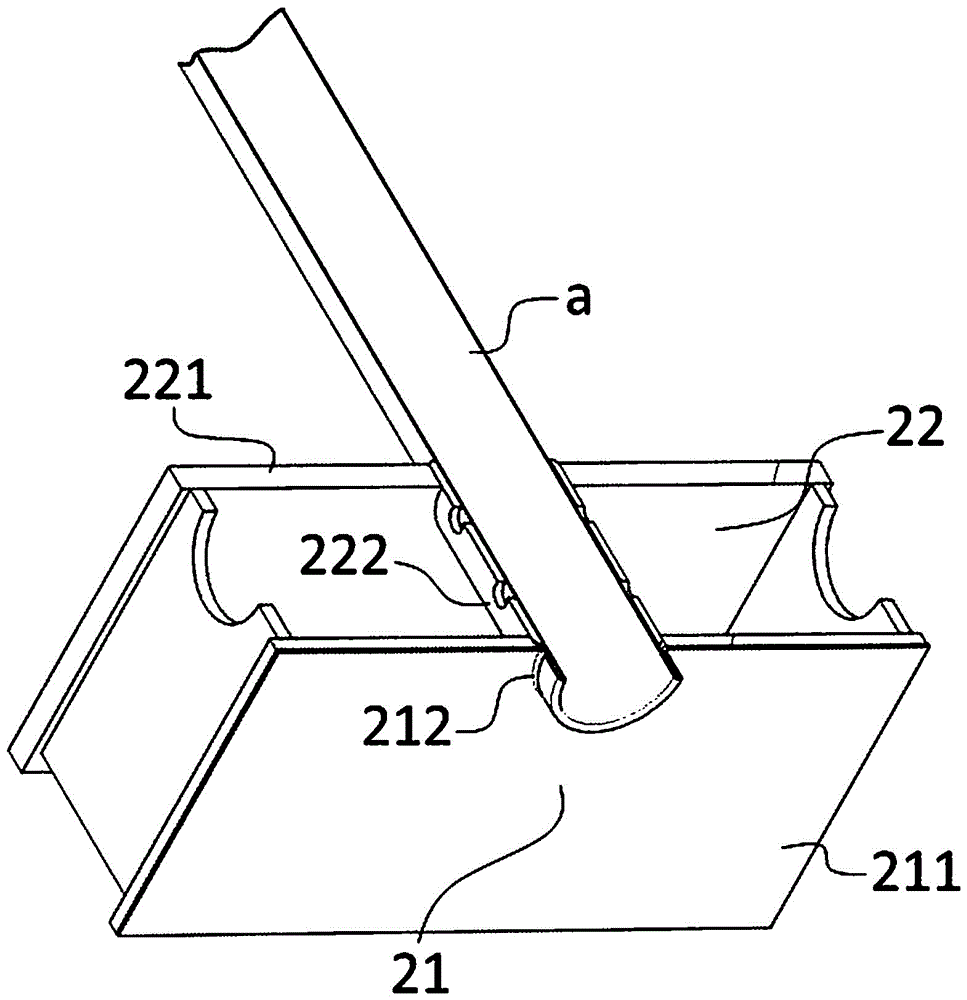

[0028] Example 1: Reference figure 1 and figure 2 , a lower plate sealing structure of a gas-gas heat exchanger, comprising a heat exchange tube limiting portion 21 and a lower plate high pressure air sealing portion 22 located above the heat exchange tube limiting portion 21;

[0029] The heat exchange tube limiting part 21 includes a first lower orifice plate 211, and the first lower orifice plate 211 is provided with a first lower hole for the heat exchange tube a to pass through. The lower surface of the first lower orifice plate 211 , The edge of the first lower hole is also provided with a limit protrusion 212, the outer surface of the limit protrusion 212 is a curved arc surface, and it is gathered inward from top to bottom, and the lower end of the heat exchange tube a is set Limiting part a-2, the limiting part a-2 is a lower edge formed by turning the lower edge of the heat exchange tube a outward, and the lower edge is formed with the outer wall of the heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com