An inclined silicon pinpoint and a manufacturing method thereof

A manufacturing method and a tilting technology, which are applied in the field of micro-nano device preparation, can solve problems such as the inability to meet the needs of near-field optical real-time observation, and achieve the effects of being suitable for large-scale production, simple manufacturing methods, and cheap and readily available raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] As mentioned above, in view of the shortcomings in the prior art, the inventor of the present case, after long-term research and extensive practice, specially proposed the technical solution of the present invention, and obtained unexpectedly good technical effects. The technical solutions of the present invention will be explained in more detail in conjunction with the embodiments and the drawings as follows.

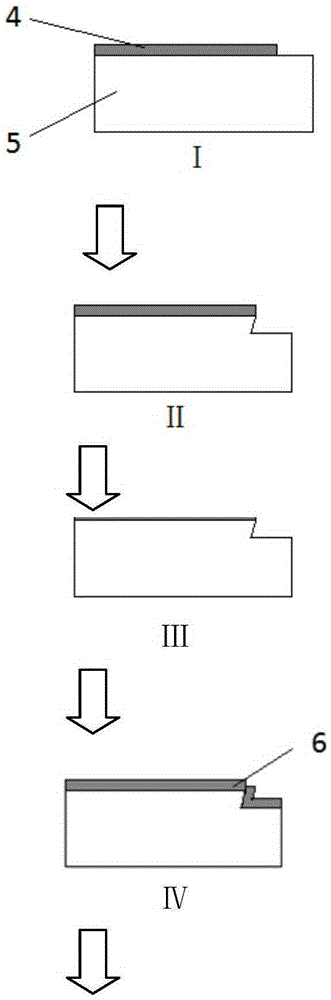

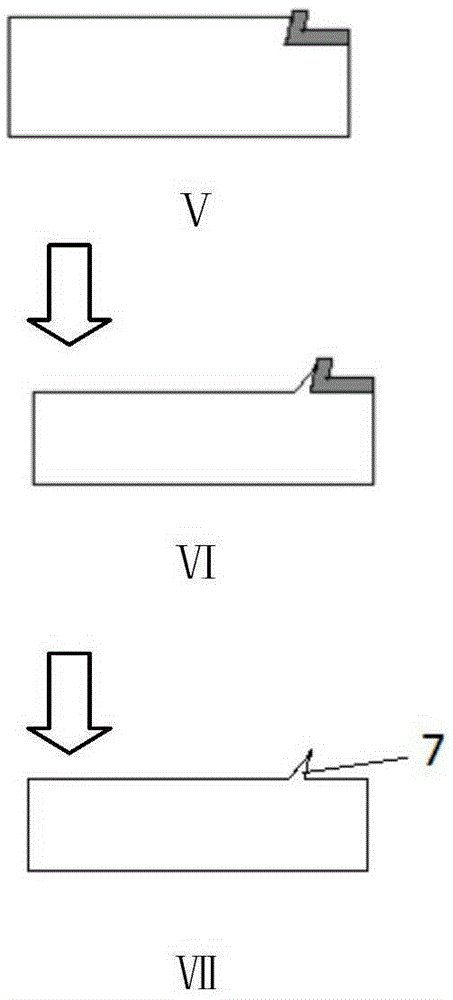

[0028] See Figure 1-2 , Which shows a typical implementation case of the present invention.

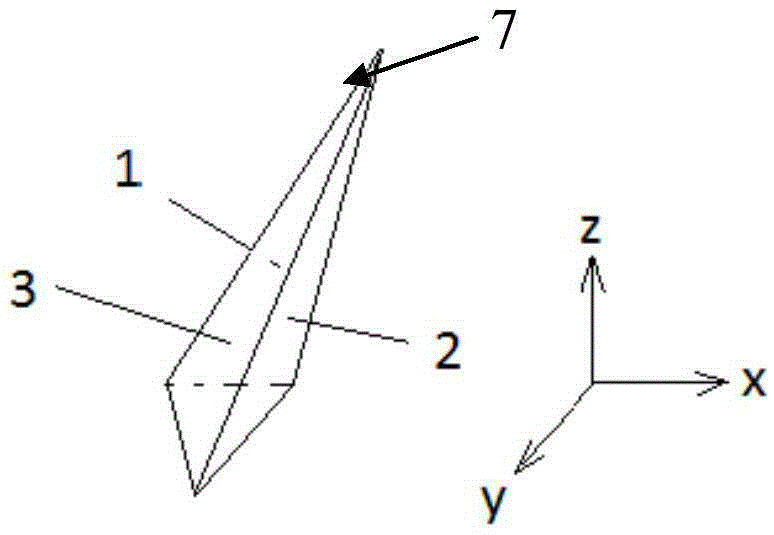

[0029] Further, please refer to figure 1 , This embodiment relates to an inclined silicon tip, which is a triangular pyramid and has a first inclined surface, a second inclined surface, a third inclined surface and a bottom surface, and the first inclined surface, the second inclined surface and The angles between at least two of the third inclined surfaces and the bottom surface are not equal.

[0030] Wherein, the angle between the first inclined surface and the bottom su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com