Production method of yeast extract through yeast cell breakage

A yeast extract and production method technology, applied in the direction of yeast-containing food ingredients, food science, food ingredients as taste improvers, etc., can solve the problems of increasing reaction costs, affecting the taste of yeast extract, and complex reaction conditions, etc. Achieve the effect of simple method, increase delicious taste and mellow feeling, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

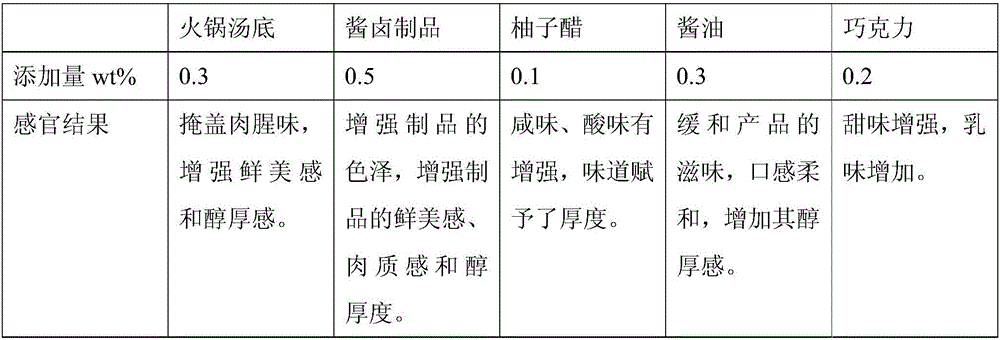

Examples

Embodiment 1

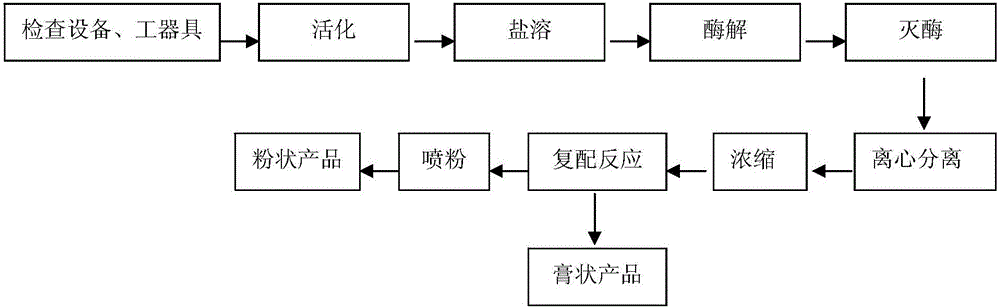

[0033] Such as figure 1 , the production method of yeast cell wall breaking and preparation of yeast extract of the present invention, comprises the following steps:

[0034] (1) Activation: add water to the activation tank, raise the temperature to 30°C, add dry yeast, stir evenly for activation, keep the temperature at 30°C for 1 hour, and obtain the yeast solution;

[0035] (2) Salt dissolution: add salt to the yeast solution, raise the temperature to 55°C, and continue stirring for 5.5 hours to open and break the cell wall of the yeast to dissolve the contents of the yeast cells;

[0036] (3) Enzymolysis: Yeast extract enzyme is added, and the yeast extract enzyme will cut the long-chain protein released from the cells into amino acids, embryos and other substances, stimulate the fresh fragrance of yeast, and obtain the enzymatic hydrolysis solution;

[0037] (4) Enzyme inactivation: inactivate the enzymatic hydrolyzate in step (3) at 90°C for 30 minutes;

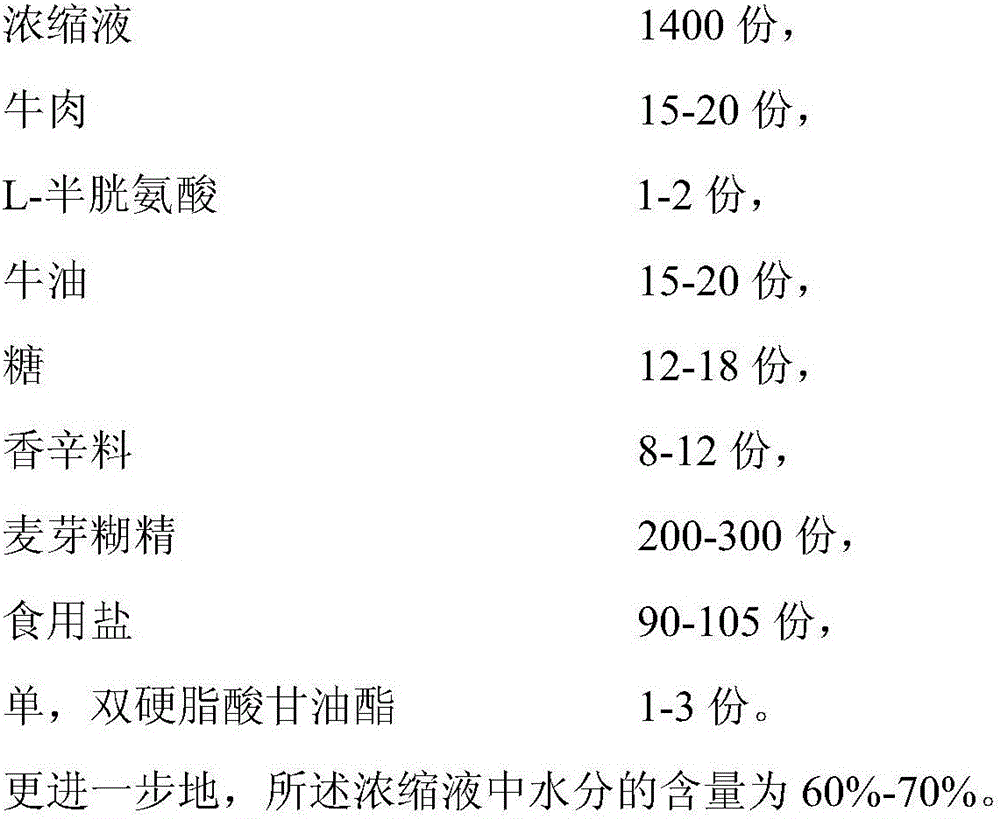

[0038] (5) ce...

Embodiment 2

[0046] The production method of yeast cell wall breaking and preparation of yeast extract of the present invention comprises the following steps:

[0047] (1) Activation: add water to the activation tank, raise the temperature to 27°C, add dry yeast, stir evenly to activate, keep the temperature at 27°C, and the time is 1.5 hours to obtain the yeast solution;

[0048] (2) Salt dissolution: add salt to the yeast solution, raise the temperature to 50°C, and continue stirring for 6 hours to open and break the cell wall of the yeast to dissolve the contents of the yeast cells;

[0049] (3) Enzymolysis: Yeast extract enzyme is added, and the yeast extract enzyme will cut the long-chain protein released from the cells into amino acids, embryos and other substances, stimulate the fresh fragrance of yeast, and obtain the enzymatic hydrolysis solution;

[0050] (4) Enzyme inactivation: inactivate the enzymatic hydrolyzate in step (3) at 92°C for 40 minutes;

[0051] (5) centrifugation...

Embodiment 3

[0059] The production method of yeast cell wall breaking and preparation of yeast extract of the present invention comprises the following steps:

[0060] (1) Activation: add water to the activation tank, raise the temperature to 32°C, add dry yeast, stir evenly to activate, keep the temperature at 32°C, and the time is 1.2 hours to obtain the yeast solution;

[0061] (2) Salt dissolution: add salt to the yeast solution, raise the temperature to 60°C, and continue stirring for 5 hours to open and break the cell wall of the yeast to dissolve the contents of the yeast cells;

[0062] (3) Enzymolysis: Yeast extract enzyme is added, and the yeast extract enzyme will cut the long-chain protein released from the cells into amino acids, embryos and other substances, stimulate the fresh fragrance of yeast, and obtain the enzymatic hydrolysis solution;

[0063] (4) Enzyme inactivation: inactivate the enzymatic solution in step (3) at 95°C for 25 minutes;

[0064] (5) centrifugation: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com