Porous titanium cage

A technology of intervertebral fusion and porous titanium, applied in the direction of prostheses, manufacturing tools, spinal implants, etc., can solve the problems of lack of fatigue resistance, failure to meet long-term clinical conditions, and easy fracture, and achieve good elasticity and toughness , high strength, and the effect of ensuring structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

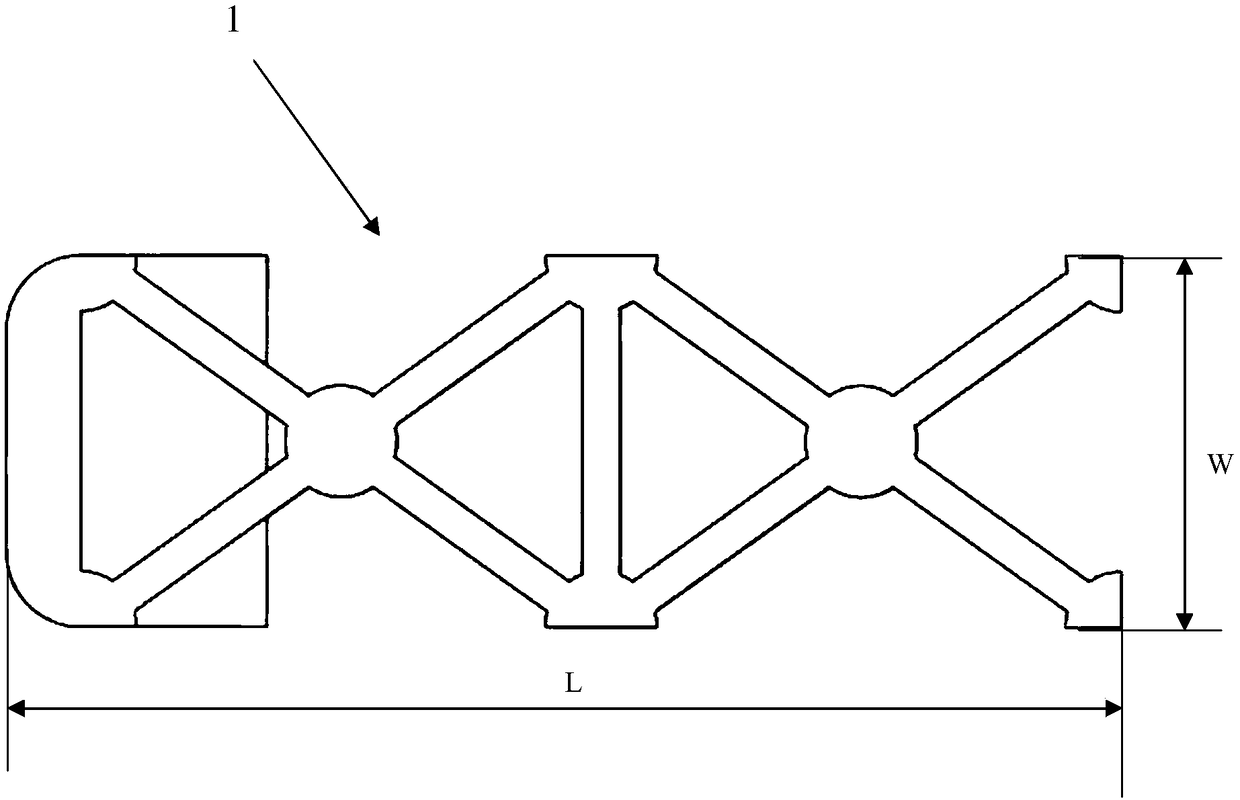

[0025] (Example 1. Porous titanium interbody fusion cage)

[0026] see Figure 5 with Image 6 The pore structure part of the porous titanium intervertebral fusion cage of this embodiment is a part of a fusion cage formed by integrally printing titanium alloy materials by a 3D printer, and the pore structure part 2 is composed of a combination of void units in a regular tetrahedral structure. ; Each void unit is composed of 4 rectangular parallelepiped cylindrical titanium pillars 21 with the same length connected together, that is, the respective ends of the 4 titanium pillars 21 are connected together, and the angle between each titanium pillar 21 is 109 The other end of each of the four titanium pillars 21 is connected to the other end of a titanium pillar corresponding to an adjacent void unit. The angle between the two connected titanium pillars is also 109 degrees and 28 minutes. That is, the connection mode between each titanium column 21 of the pore structure part and th...

Embodiment 2

[0028] (Example 2. Intervertebral fusion cage)

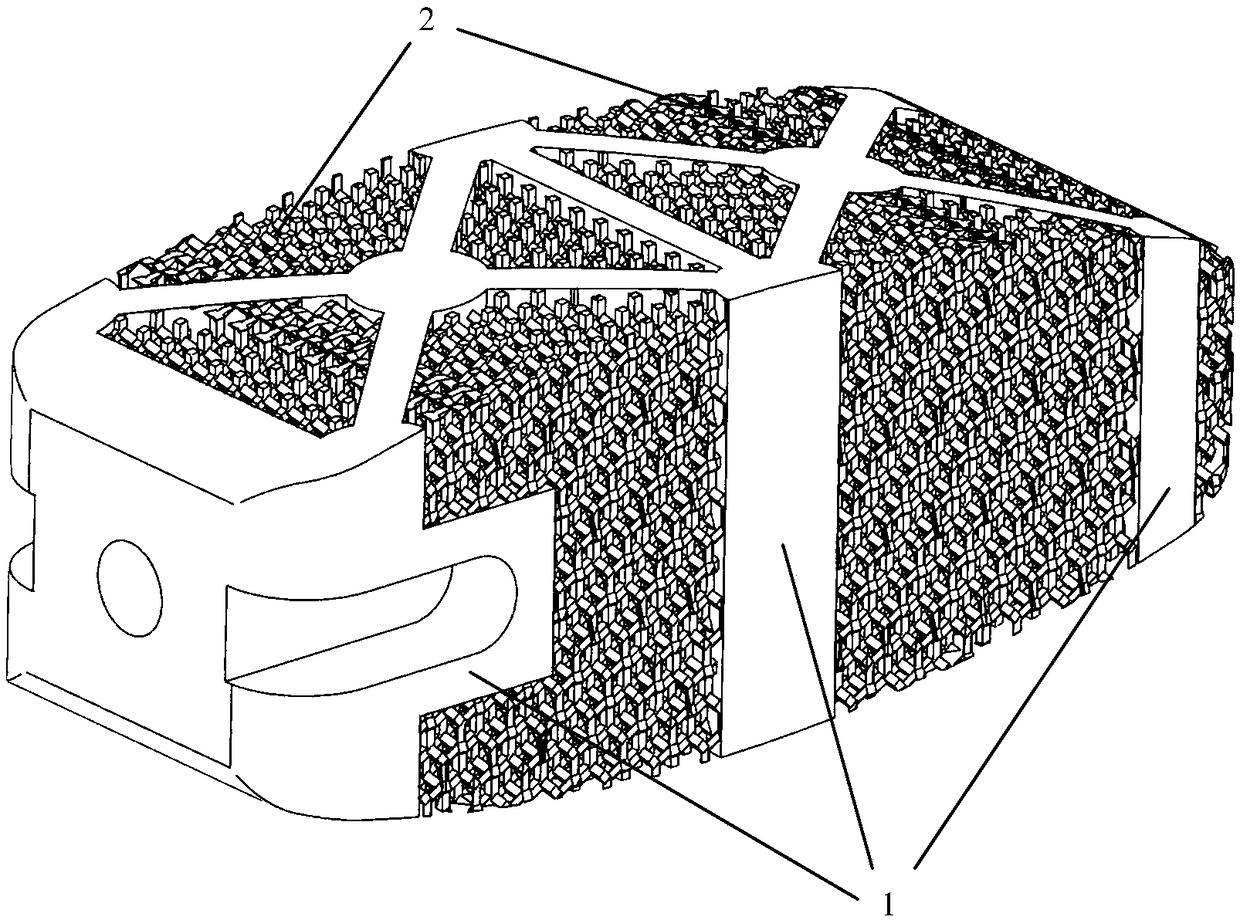

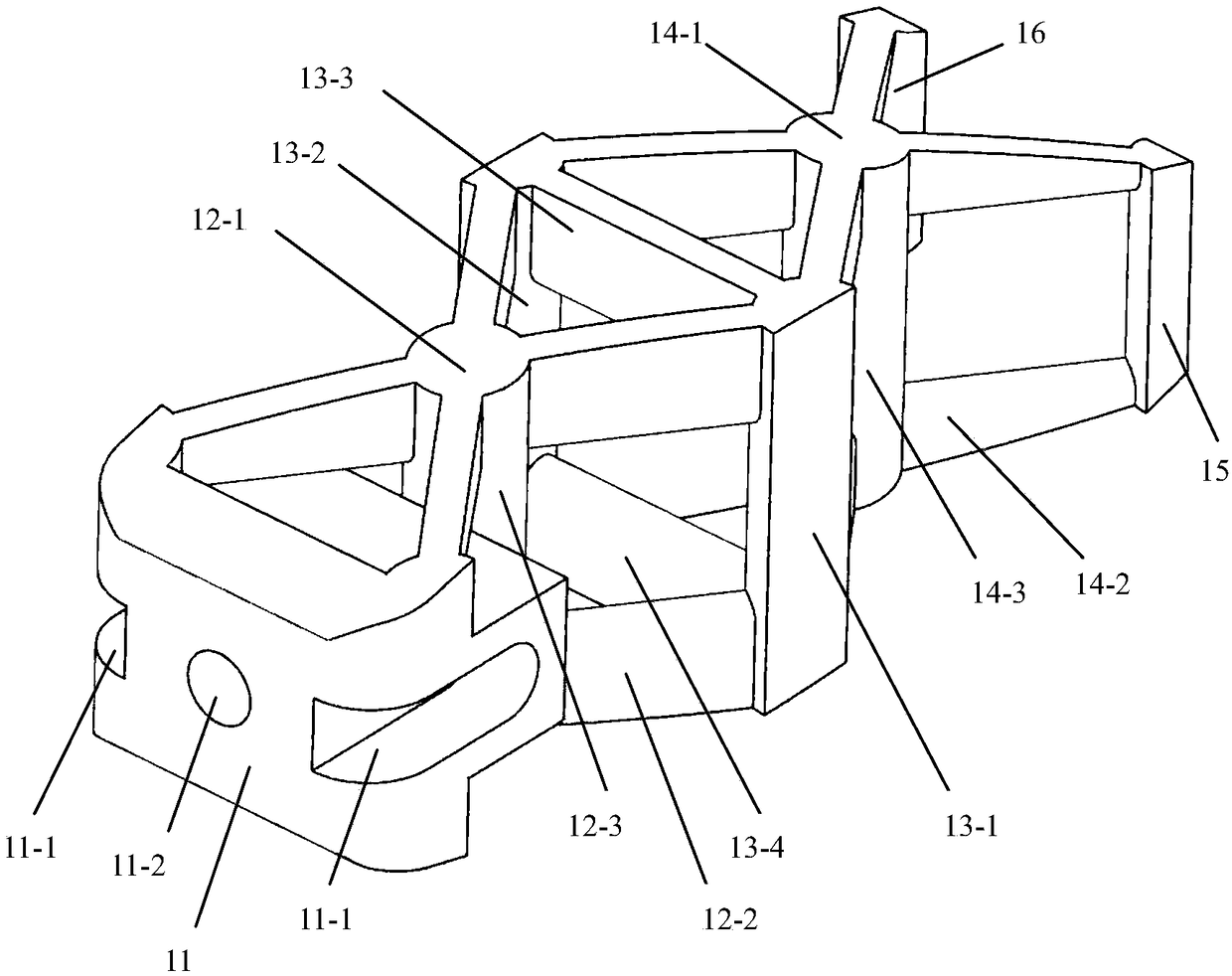

[0029] Such as figure 1 As shown, the intervertebral fusion cage of this application example is a structural part formed by integrally printing titanium alloy materials by a 3D printer. The pore structure device of the cage is divided into a supporting structure part 1 and a pore structure part 2 according to different functions. The supporting structure portion 1 and the pore structure portion 2 are integrally fixedly connected to each other. The supporting structure part 1 is used to bear the external load, and the pore structure part 2 is used to guide the growth of new bone; the volume of the supporting structure part 1 accounts for 10% of the total volume of the cage. The pore structure part 2 is exposed to the outside in an open manner on the upper, lower, front, back and right sides of the support structure part 1, and at corresponding locations on the front, back and right sides of the support structure part 1. It is loca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com