Cold-resistant environment-friendly water fire extinguishing agent

A kind of fire extinguishing agent, environmental protection technology, applied in the production field of cold-resistant and environment-friendly water-based fire extinguishing agent, can solve the problems of affecting the toxicity of water-based fire extinguishing agent, increasing the amount of antifreeze, etc., and achieve long storage period, good fire extinguishing, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

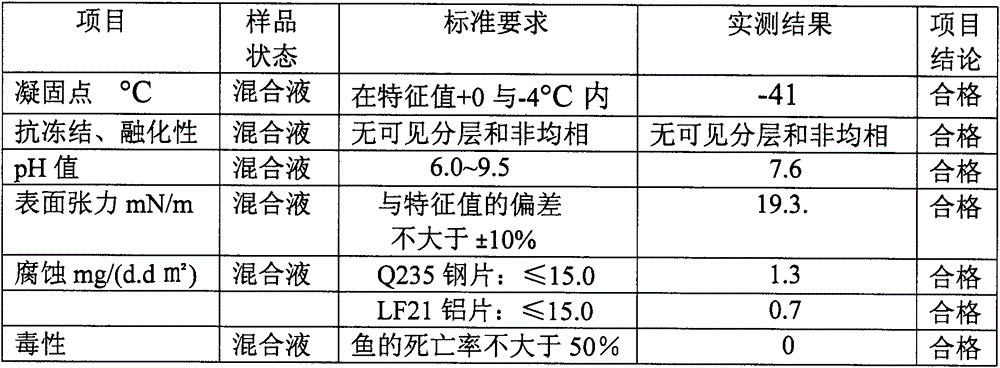

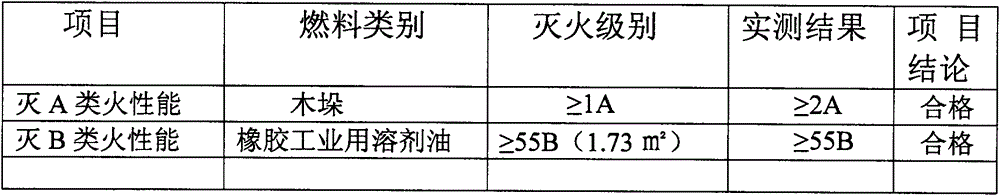

Embodiment 1

[0037] Embodiment one (3% water system fire extinguishing agent)

[0038] 1. Consists of the following components by weight:

[0039] Monoammonium Phosphate 7kg

[0040] Potassium bicarbonate 7 kg

[0041] Zinc borate 0.7 kg

[0042] Urea 10kg

[0043] Thickener (xanthan gum) 0.8 kg

[0044] Composite hydrocarbon surfactant (CAB-35+APG-0810) 24 kg

[0045] Compound fluorocarbon surfactant (JF1127A) 4.5 kg

[0046] Antifreeze (diethylene glycol butyl ether) 40 kg

[0047] 20 kg of water

[0048] 2. Production process:

[0049] (1) Potassium bicarbonate is mixed evenly with the thickener, and slowly added to the stirred water to fully dissolve;

[0050] (2) Zinc borate, monoammonium phosphate, and urea are slowly added in the above-mentioned solution that is stirred successively, and the latter material is added after the former material is fully dissolved;

[0051] (3) Antifreeze is added to the above solution that is stirred and fully dissolved;

[0052] (4) after a...

Embodiment 2

[0058] Embodiment two (6% water system fire extinguishing agent)

[0059] 1. It consists of the following components by weight:

[0060] Monoammonium Phosphate 7.8 kg

[0061] Potassium bicarbonate 7.7 kg

[0062] Zinc borate 0.7 kg

[0063] Urea 12kg

[0064] Thickener (xanthan gum) 0.8 kg

[0065] Composite hydrocarbon surfactant (CAB-35+APG-0810) 18kg

[0066] Compound fluorocarbon surfactant (JF1127A) 4 kg

[0067] Antifreeze (diethylene glycol butyl ether) 40 kg

[0068] 28 kg of water

[0069] 2. Production process:

[0070] (1) Potassium bicarbonate is mixed evenly with the thickener, and slowly added to the stirred water to fully dissolve;

[0071] (2) Zinc borate, monoammonium phosphate, and urea are slowly added in the above-mentioned solution that is stirred successively, and the latter material is added after the former material is fully dissolved;

[0072] (3) Antifreeze is added to the above solution that is stirred and fully dissolved;

[0073] (4) af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com