Preparation method of extracting agent for innocent treatment of industrial waste oil

A technology for harmless treatment of industrial waste oil, applied in chemical instruments and methods, petroleum industry, separation methods, etc., can solve problems such as unsatisfactory effects, and achieve the effect of enhancing the effect of oil-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 30 milliliters of N,N-dimethylformamide, 10 g of β-cyclodextrin and 7 g of 2-hydroxy-propanetricarboxylic acid successively to a three-necked flask connected with a stirring device, stir and react at 60°C for 20 hours, Cool and filter, wash the filter cake three times with acetone, and dry at 50°C for 24 hours to obtain 9.1 g of white solid powder of cyclodextrin-2-hydroxy-propanetricarboxylate.

[0019] Take 0.5g of cyclodextrin-2-hydroxyl-propylene tricarboxylate, 20g of n-hexane, 28g of n-octane, 38g of cyclohexane, 1.5g of ethanol and 0.1 water in a 250mL three-necked flask, 25 Stirring at ℃ for 15 minutes to prepare an extractant for harmless treatment of industrial waste oil, which is used to treat industrial waste oil produced by drilling tools or drilling machines.

Embodiment 2

[0021] Add 80ml of N,N-dimethylformamide, 12g of β-cyclodextrin and 9g of 2-hydroxy-propanetricarboxylic acid in sequence to a three-necked flask connected with a stirring device, stir and react at 90°C for 50 hours , cooled and filtered, the filter cake was washed 3 times with acetone, and dried at 50° C. for 24 hours to obtain 11.0 g of white solid powder of cyclodextrin-2-hydroxy-propanetricarboxylate.

[0022] Take 1.5g of cyclodextrin-2-hydroxyl-propylene tricarboxylate, 30g of n-hexane, 32g of n-octane, 45g of cyclohexane, 2.0g of ethanol and 1.0g of water in a 250mL three-necked flask, Stir at 30°C for 15 minutes to prepare an extractant for harmless treatment of industrial waste oil, which is used for industrial waste oil produced in product oil tanks.

Embodiment 3

[0024] Add 60 ml of N,N-dimethylformamide, 11.35 g of β-cyclodextrin, and 8 g of 2-hydroxy-propanetricarboxylic acid in sequence to a three-necked flask connected with a stirring device, stir and react at 80°C for 24 hours, cooled and filtered, the filter cake was washed 3 times with acetone, and dried at 50°C for 24 hours to obtain 10.8 g of cyclodextrin-2-hydroxyl-propylene tricarboxylate white solid powder.

[0025] Take 1g of cyclodextrin-2-hydroxyl-propylene tricarboxylate, 25g of n-hexane, 28.5g of n-octane, 43g of cyclohexane, 2g of ethanol and 0.5g of water in a 250mL three-necked flask for 30 Stir at ℃ for 15 minutes to prepare an extractant for harmless treatment of industrial waste oil. The extractant obtained by this formula is mainly suitable for industrial waste oil produced in various fields such as ship transportation and oil field operations.

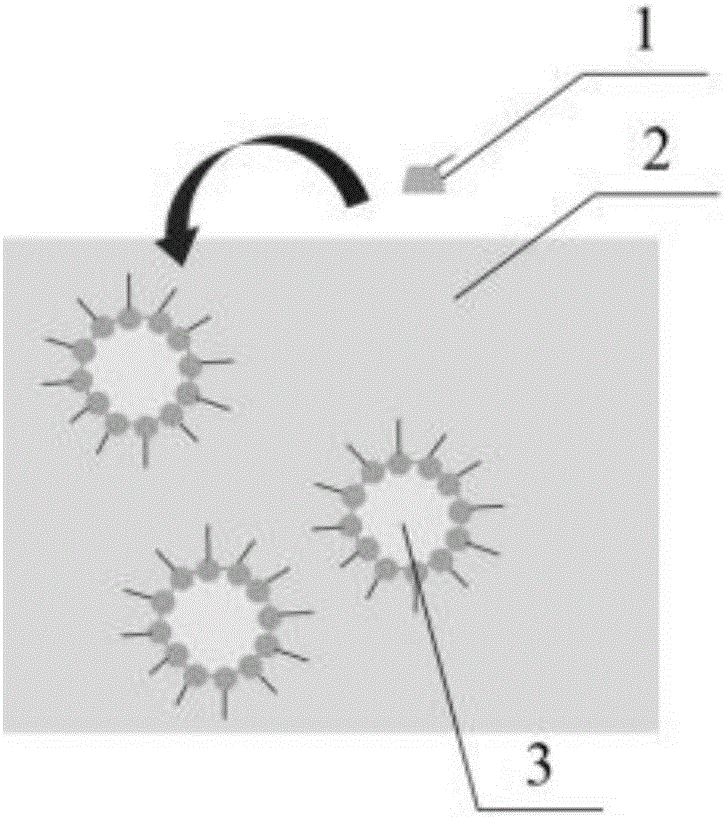

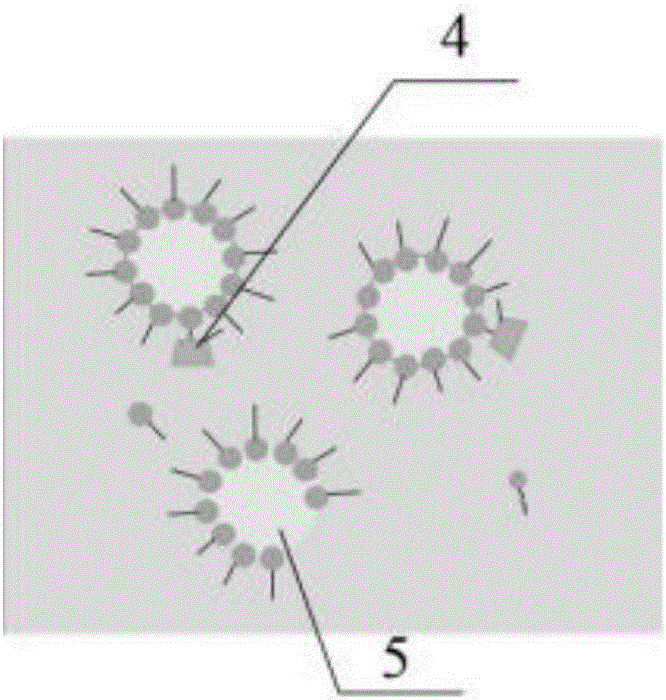

[0026] Such as figure 1 , figure 2 As shown, after cyclodextrin-2-hydroxy-propanetricarboxylate enters the oil pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com