Soft-material high-polymer precision filter used for infusion and manufacturing method thereof

A precision filter and polymer technology, applied in the field of medical devices, can solve problems such as low production efficiency and good product rate, complex manufacturing process, and high cost, and achieve the goal of improving filtration efficiency and effect, product qualification rate, and production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, and the present invention is not limited to the following embodiments.

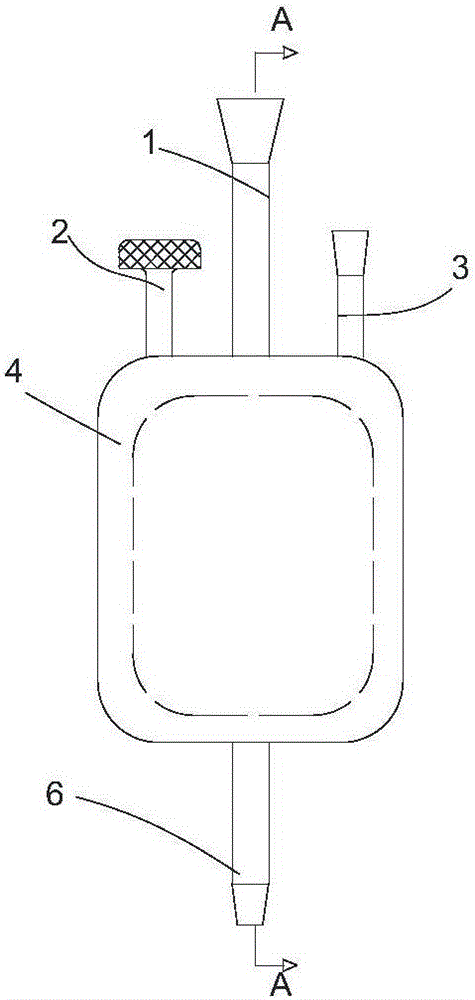

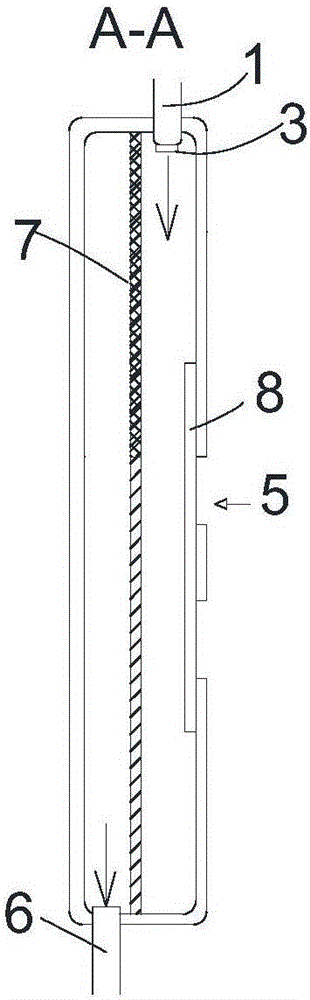

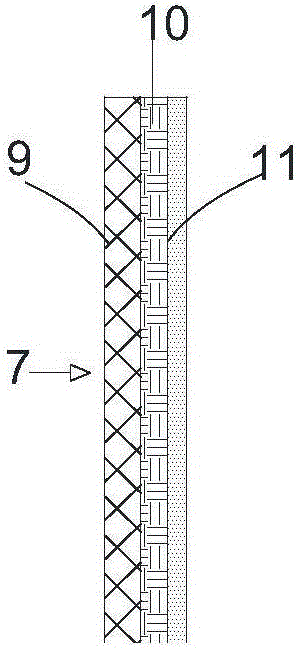

[0033] Such as figure 1 As shown, a soft polymer precision filter for infusion includes: a filter bag 4 made of light film material, and a filter cavity and a liquid discharge cavity are formed by setting a precision filter 7 inside the filter bag 4; the filter bag The upper end of 4 is provided with input joint 1 and dosing joint 3, and both input joint 1 and dosing joint 3 are connected with the liquid discharge cavity; The bag 4 is also provided with venting means. Before the vent hole 5 is not in use, the vent shell 9 is provided with an air film that seals the vent hole. The precision filter 7 is arranged between the two side walls of the filter bag 4, and formed by ultrasonic welding or high-frequency heat welding. Both the input connector 1 and the output connector...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Filter pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com