Micro-fluidic chip and preparation method and application thereof

A technology of microfluidic chips and microfluidic channels, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems of cumbersome steps, low separation efficiency, dead cells, etc., and achieve comprehensive Low cost, good application prospect, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

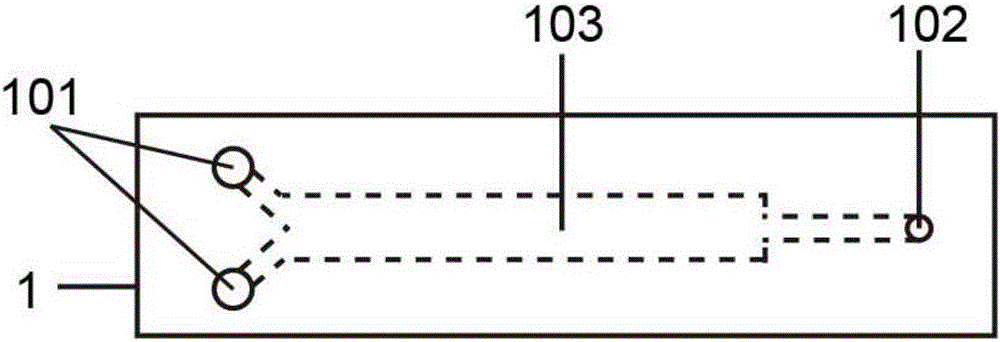

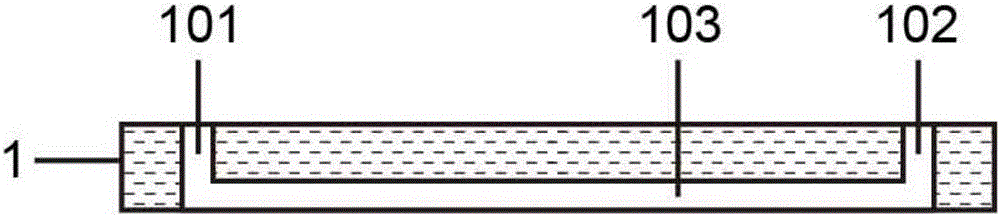

[0030] Such as figure 1 with 2 As shown, the structure of the encapsulation layer 1 includes an encapsulation layer inlet 101, an encapsulation layer outlet 102 and an encapsulation layer microfluidic channel 103, and the three are connected to each other, and liquid can enter from the encapsulation layer inlet 101 and flow through the encapsulation layer microfluidic channel 103. The channel 103 exits from the outlet 102 of the encapsulation layer.

[0031] Such as image 3 with 4 As shown, the base layer 2 is a plate-like structure without holes.

[0032] Such as Figure 5 with 6 As shown, the microfluidic chip contains three porous membrane layers and three support layers. For ease of distinction, the three-layer porous membrane layers are named respectively as the first porous membrane layer 3, the second porous membrane layer 5 and the third porous membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com