Automatic alarm device for material blockage of three-product dense-medium cyclone

A technology of automatic alarm device and heavy medium cyclone, applied in the direction of cyclone device, solid separation, etc., can solve the problems of material blocking accident, accident expansion, limited passing capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment, further illustrate the present invention.

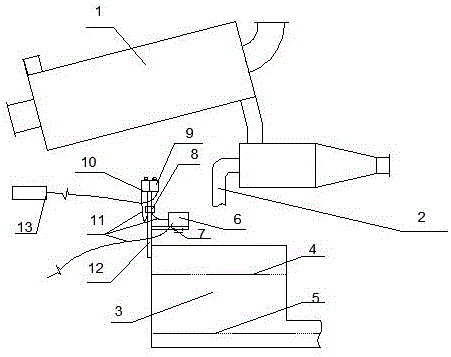

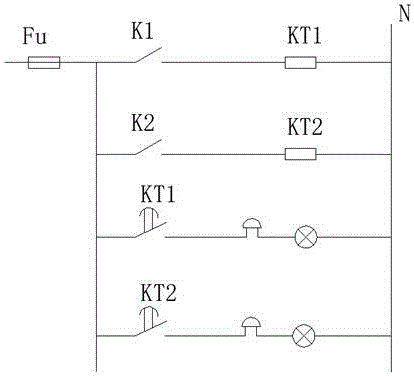

[0019] see figure 1 , figure 2 , an automatic alarm device for material blocking of a three-product dense medium cyclone, which is composed of an ultrasonic liquid level switch 6 and an audible and visual alarm; the three-product dense medium cyclone 1 is provided with a medium coal discharge port 2, and a medium coal discharge Port 2 discharges to the medium coal collection box 3, the ultrasonic liquid level switch 6 is set above the medium coal collection box 3, and the ultrasonic liquid level switch 6 is set in the medium coal collection box 3 to monitor the high liquid level 4 and the low level The liquid level 5, the ultrasonic liquid level switch 6 are electrically connected with the delay relay control box 8, and the delay relay control box 8 is equipped with a delay relay KT1, a delay relay KT2, a delay relay KT1 and a high liquid level sound and light al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com