A supercritical carbon dioxide pulse jet oil pipe cleaning device and method

A carbon dioxide, pulse jet technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of limited cleaning fluid discharge, frequent replacement of wire brushes, and unsatisfactory cleaning effects. Good application prospects, low energy loss, and the effect of reducing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described through embodiment.

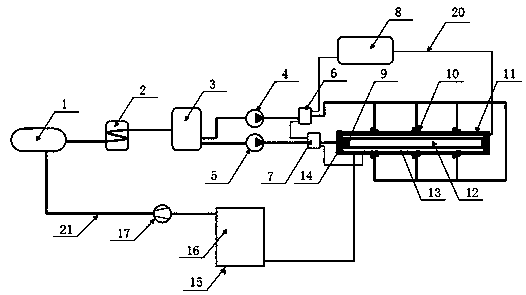

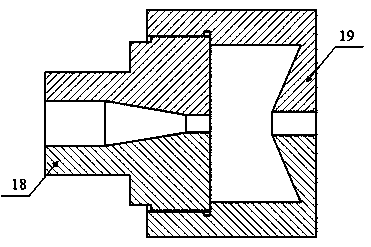

[0020] Such as figure 1 As shown, the main structure of the present invention includes gaseous carbon dioxide storage device 1, refrigeration device 2, liquid carbon dioxide storage device 3, high-pressure pump one 4, high-pressure pump two 5, supercritical carbon dioxide storage device one 6, supercritical carbon dioxide storage device two 7 , heating device 8, center self-excited oscillation pulse nozzle 9, side self-excited oscillation pulse nozzle 10, cleaning chamber 11, oil pipe 12, cleaning chamber end cover 14, crude oil discharge port 15, oil-gas separation device 16, carbon dioxide gas compression device 17, and hot water pipeline 20 and carbon dioxide pipeline 21.

[0021] The right end of the gaseous carbon dioxide storage device 1 is connected to the refrigeration device 2 through a pipeline, and the lower part is connected to the outlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com