Melt extrusion molding device suitable for multiple metal materials

A melt extrusion, metal material technology, applied in the field of additive manufacturing, which can solve problems such as affecting forming accuracy, low viscosity of molten metal, and salivation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

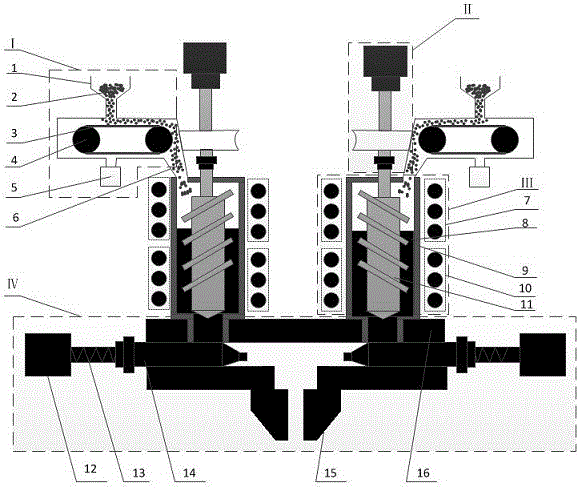

[0014] The process of using the present invention to manufacture workpieces will be described in detail below in conjunction with the accompanying drawings.

[0015] The specific implementation steps of the method of the present invention are as follows.

[0016] Add enough granular (powder) thermoplastic material (2) into the hopper (1) before work starts.

[0017] Set the heating temperature and heating efficiency of the primary induction heating coil (7) and the secondary induction heating coil (10) according to the properties of the granular (powder) thermoplastic material (2) and the properties of the molten material (8) to be obtained , to obtain the required molten material (8).

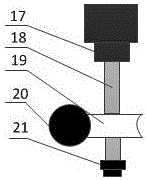

[0018] During work, the motor (17) is controlled to rotate, and the worm and gear device is used to drive the pulley (4) to rotate. The granular (powder) thermoplastic material (2) is deposited on the friction feeding belt (3) under the action of its own weight, and the friction feeding belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com