Method for electron beam welding of hollow flat tube type parts

A technology of electron beam welding and electron beam, which is applied in the field of electron beam welding of hollow flat tube parts, can solve the problems that hollow flat tubes cannot be welded at the same time, welding efficiency needs to be improved, and welding methods are lacking, so as to avoid welding defects and solve Difficult to weld and improved welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

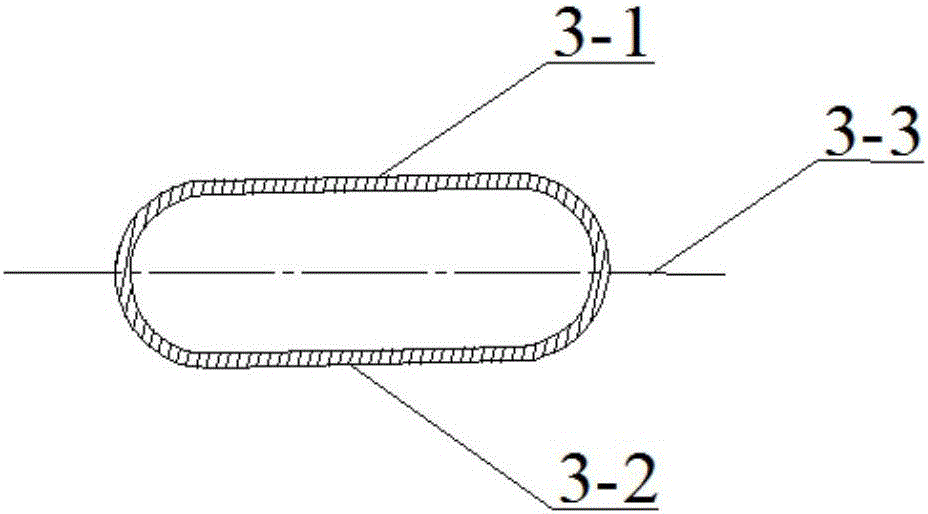

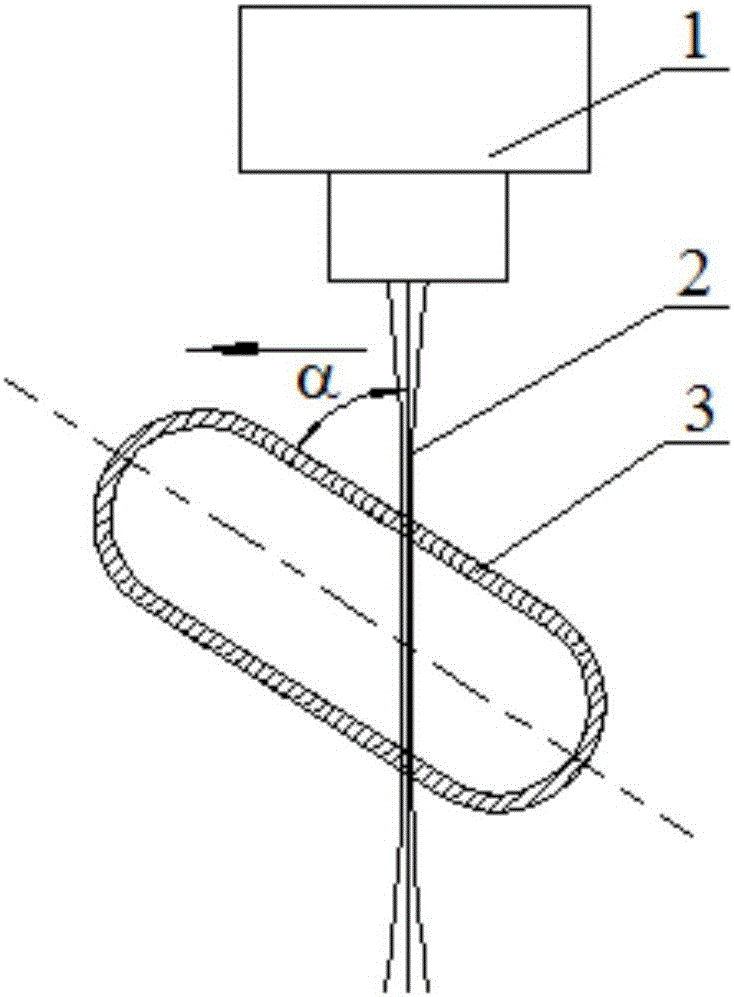

[0028] Hollow flat tube parts in the present embodiment, material is TC4 titanium alloy, and its hollow flat tube 3 is as figure 1 As shown, including the upper side 3-1 and the lower side 3-2, the position where the upper side and the lower side meet is an arc surface, and the axis of symmetry of the upper side and the lower side is the long axis 3-3 of the hollow flat tube. The wall thickness of the flat tube is 1.8 mm to 2.2 mm, and there is no shielding part on both sides of the welding part.

[0029] In this embodiment, the electron beam acceleration voltage of the electron beam generator 1 is 60KV-150KV, the welding speed (moving speed of the electron beam generator) is 10mm / sec-20mm / sec, and the electron beam current varies with the welding thickness according to the following formula :

[0030] E=(U·I) / (V·T)

[0031] Where E is the input energy per unit time and unit thickness of the welding part, U is the electron beam acceleration voltage, I is the electron beam cu...

Embodiment 2

[0040] In this embodiment, for Figure 5 The shown casing main body 7 and the pipe joint 9 are welded, and the welded parts of the pipe joint 9 and the casing main body 7 are hollow flat tubes (see Figure 4 ), the length L=60.5mm of the cross-section of the hollow flat tube 3, the width B=30mm, the wall thickness is 2.0mm, and the lower side of the welding part 8 is shielded by the structure on the casing main body 7 (see Figure 5 ); The materials of casing main body 7 and pipe joint 9 are GH4169 superalloy.

[0041] In this embodiment, the electron beam accelerating voltage of the electron beam generator 1 is 150KV, the electron beam current varies with the welding depth (see step 3 below), and the welding speed (moving speed of the electron beam generator) is 20mm / s.

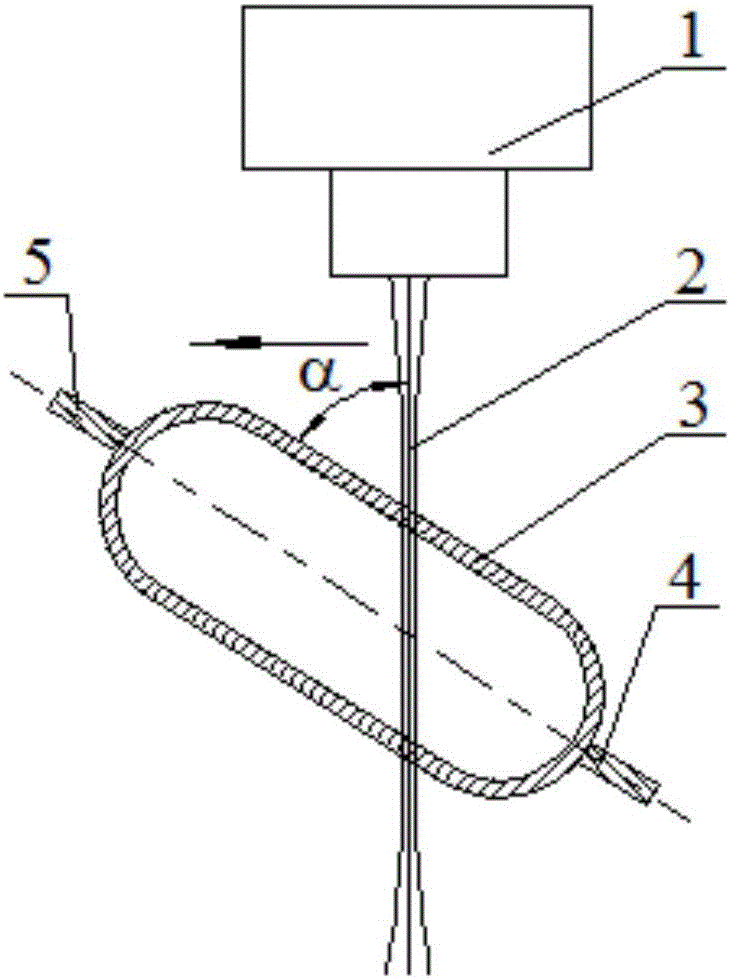

[0042] In this embodiment, the electron beam energy absorbing plate 6 is equipped, and the arc starting plate 4 and the arc receiving plate 5 are fixedly connected by tack welding on both sides of the weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com