Welding fixture for rear fork of cross country motorcycle frame

A technology for welding fixtures and motorcycles, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unguaranteed welding quality and low work efficiency, and achieve improved welding efficiency, improved welding quality, and improved The effect of pinpointing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

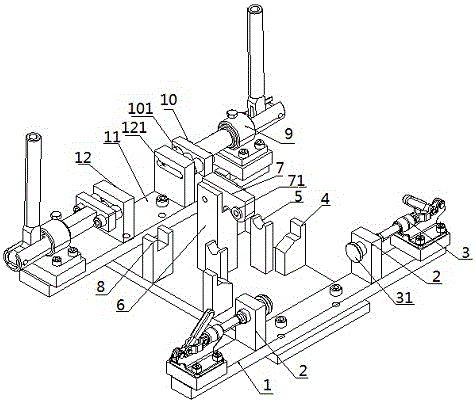

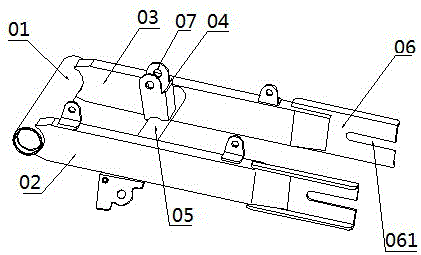

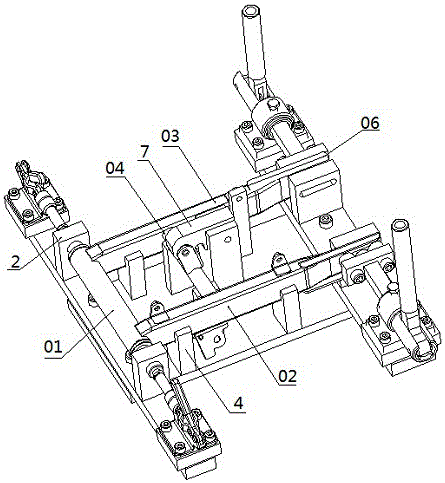

[0026] like figure 1 As shown, a welding fixture for the rear fork of the off-road motorcycle frame of the present embodiment includes a tooling base plate and various supports arranged on the tooling base plate. The supports include a front support 4, a shock absorbing seat tube support 5 and a rear support 8, and the tooling base plate The middle part and both sides of the central axis along its length direction are provided with front support 4, shock absorbing seat tube support 5 and rear support 8 successively from front to rear, and the front support 4, shock absorbing seat tube support 5 and rear support 8 on both sides The supports 8 are all arranged symmetrically along the width direction of the above-mentioned tooling base plate, and each support corresponds to each part of the rear fork of the off-road motorcycle frame, such as figure 2 As shown, the sides of the two ends of the rear fork shaft 01 of the off-road motorcycle frame rear fork of the present embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com