Infrared detector with micro-bridge structure and manufacturing method thereof

A technology of infrared detector and microbridge structure, which is applied in the field of infrared detectors, can solve the problems of complex surface structure of infrared absorbing layer, microbridge thermal insulation failure, and lower yield rate, so as to avoid the contact between the suspended part and the microbridge structure, Effects of Reducing Difficulty, Improving Performance and Yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

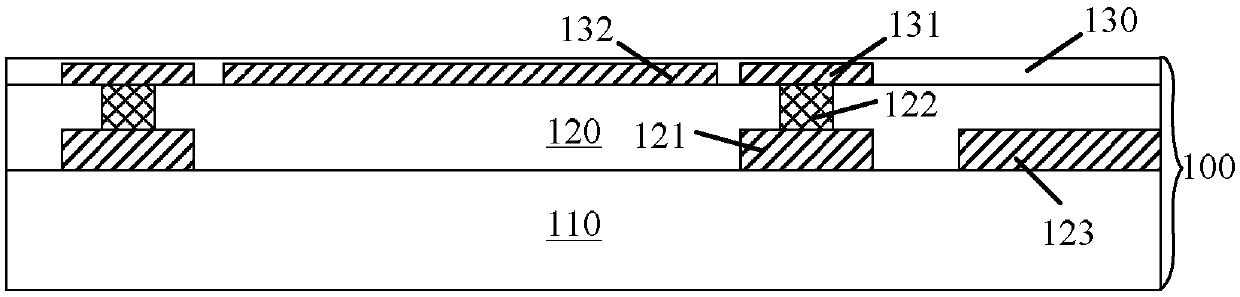

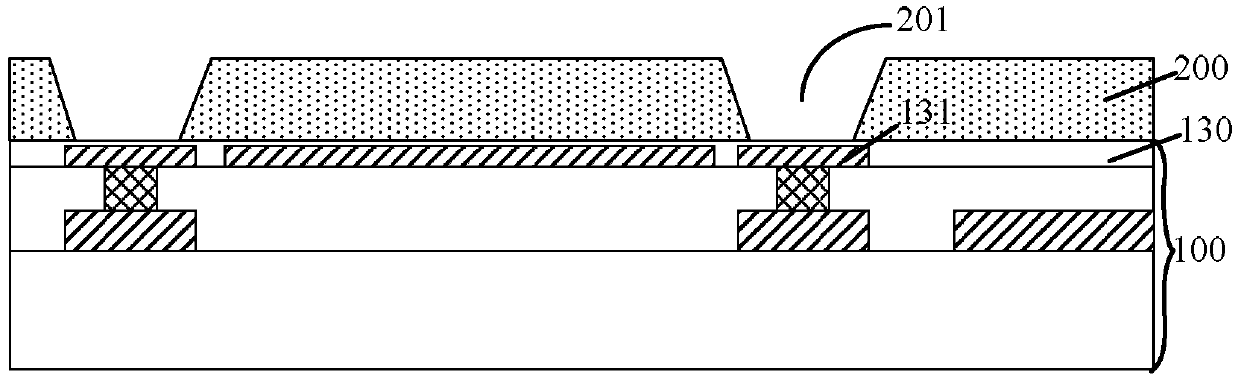

[0026] The specific implementation of the infrared detector with micro-bridge structure and its manufacturing method provided by the present invention will be described in detail below with reference to the accompanying drawings.

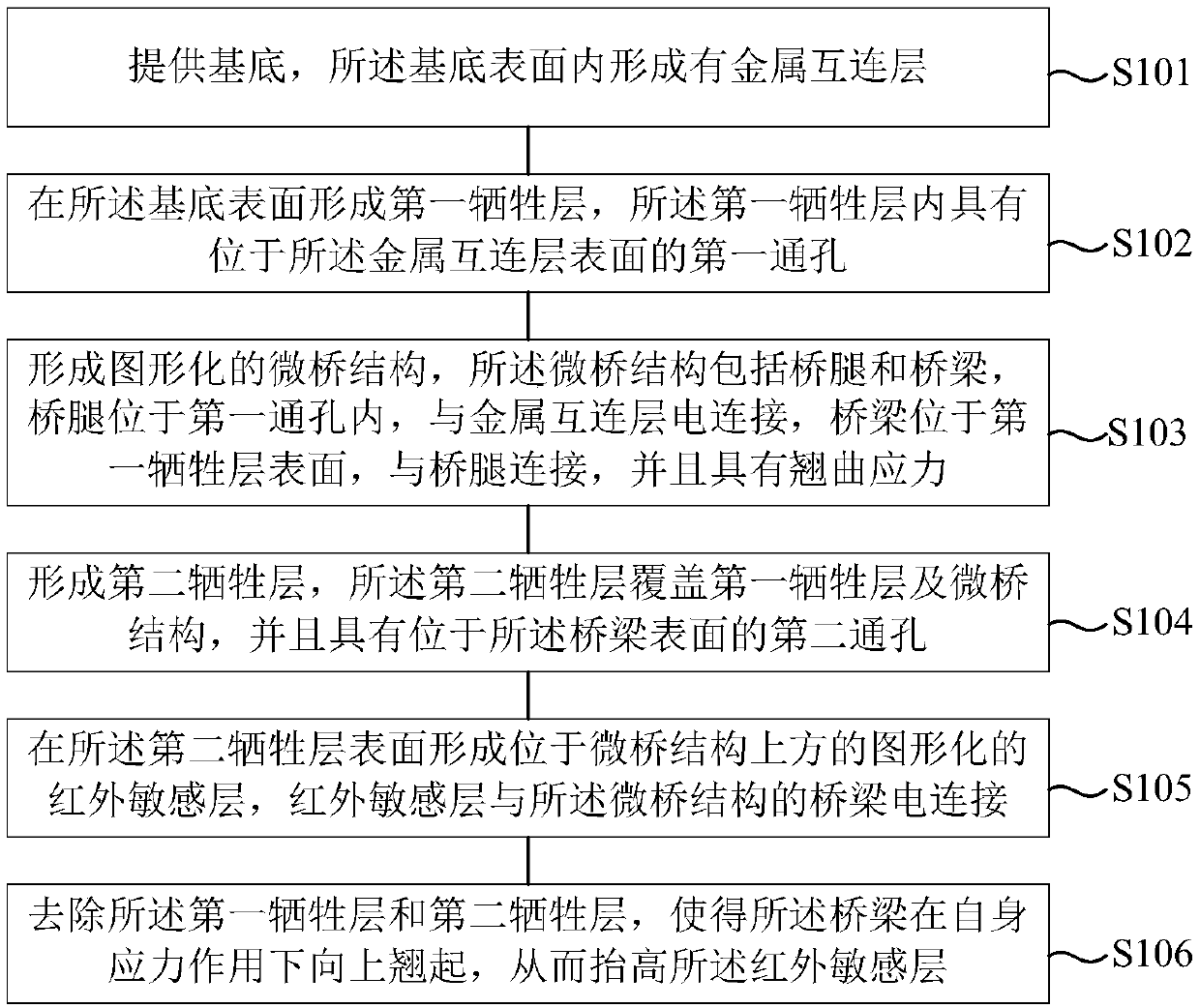

[0027] Please refer to figure 1 , is a flow chart of a method for manufacturing an infrared detector with a microbridge structure according to a specific embodiment of the present invention.

[0028] The manufacturing method of described infrared detector comprises:

[0029] Step S101: providing a substrate, a metal interconnection layer is formed in the surface of the substrate.

[0030] Step S102: forming a first sacrificial layer on the surface of the substrate, the first sacrificial layer having a first through hole located on the surface of the metal interconnection layer in the first sacrificial layer.

[0031] Step S103: forming a patterned micro-bridge structure on the inner wall surface of the first through hole and the surface of the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com