High-efficiency hydraulic air dissolving device used for dissolved air flotation

A dissolved air flotation and hydraulic technology, applied in the direction of flotation water/sewage treatment, etc., can solve the problems of large return flow, low utilization rate of compressed air, and fluctuation of effluent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

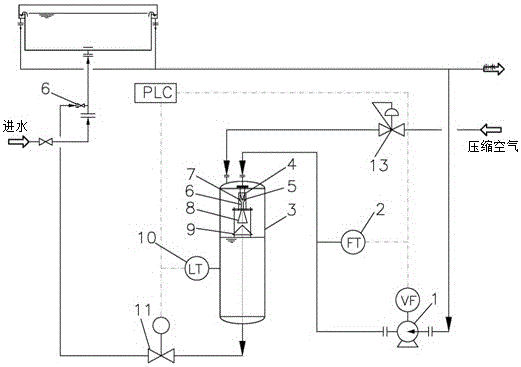

[0027] Embodiment 1, return flow is 5~10m 3 / h high-efficiency hydraulic dissolving device

[0028] It consists of 1 unit with an output of 10m 3 / h, a return pressure pump with a head of 0.6-0.7MPa (frequency conversion control), a dissolved air tank with a diameter of 500mm, and a set of output of 10m 3 / h hydraulic air mixing device and liquid level control. Regulate the pressure in the dissolved air tank at 5-6 bar through the compressed air intake control valve. Adjust the residence time of dissolved air water in the air dissolved tank through liquid level control to not less than 3 minutes; the diameter of the nozzle of the hydraulic air mixer is not greater than 13mm, and the air saturation of the dissolved air water outlet will exceed 92%.

Embodiment 2

[0029] Embodiment 2, return flow is 20~40m 3 / h high-efficiency hydraulic dissolving device

[0030] It is also composed of 1 unit with an output of 40m 3 / h, a return pressure pump with a head of 0.6-0.7MPa (frequency conversion control), a dissolved air tank with a diameter of 800mm, and a set with an output of 40m 3 / h hydraulic air mixing device and liquid level control. Regulate the pressure in the dissolved air tank at 5-6 bar through the compressed air inlet control valve. Adjust the residence time of dissolved air water in the air dissolved tank through the liquid level control device to not less than 4 minutes; the diameter of the nozzle of the hydraulic air mixer is not greater than 20mm, and the air saturation of the dissolved air water outlet will exceed 95%.

Embodiment 3

[0031] Embodiment 3, return flow is 50~60m 3 / h high-efficiency hydraulic dissolving device

[0032] It is also composed of 1 unit with an output of 60m 3 / h, reflux pressurized pump with a head of 0.6-0.7MPa (frequency conversion control), a dissolved air tank with a diameter of 1200mm, and 4 sets of output of 10-20m 3 / h standard hydraulic-air mixing device and liquid level control, 4 sets of hydraulic-air mixing devices are arranged in two groups, 2 can be operated, or 4 can be operated at the same time to meet the requirements of different return flow changes. Regulate the pressure in the dissolved air tank at 4.5-5.5 bar through the compressed air intake control valve. Adjust the residence time of the dissolved air water in the air dissolved tank through the liquid level control device to not less than 4 minutes, and the air saturation of the dissolved air water outlet will exceed 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com