Method and apparatus for removing total organic carbon in emulsification liquid biochemical effluent

A biochemical effluent and total organic carbon technology, applied in the field of water treatment, can solve the problems of emulsion biochemical effluent environmental pollution and other problems, and achieve good social and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

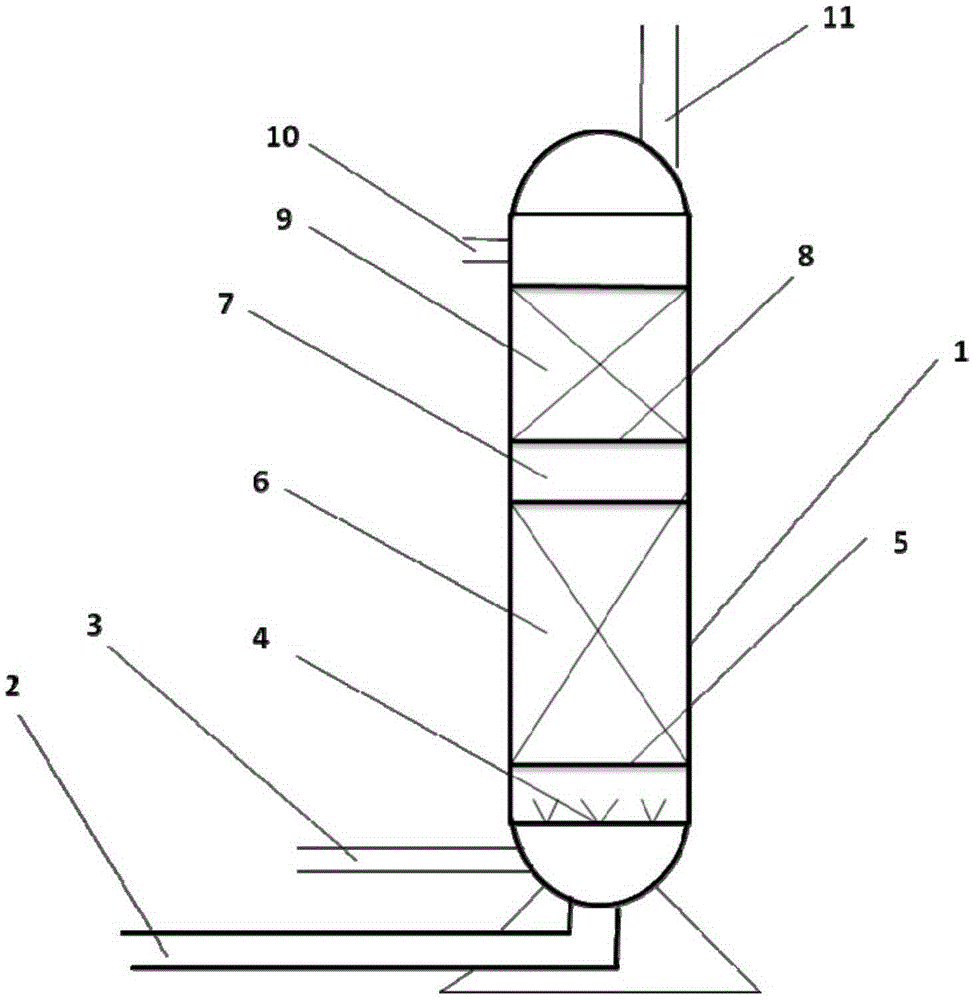

[0050]A process system for removing total organic carbon in an emulsion biochemical effluent, including a double-layer high-efficiency catalytic reaction tower, an ozone inlet, a water inlet, a distributor, a bottom catalyst layer, a supported two-component complex molecular sieve catalyst, and intermediate water Layer, top catalytic adsorbent layer, loaded manganese-based activated carbon catalyst, water outlet, gas outlet.

[0051] The biochemical effluent of the emulsion refers to the wastewater treated by the anoxic and aerobic biochemical pools. The pH of the biochemical effluent of the emulsion was 7.9, and the total organic carbon was 62 mg / L.

[0052] The biochemical effluent of the emulsion enters the double-layer high-efficiency catalytic reaction tower from the waste water inlet through the lift pump. Ozone enters the reaction tower from the double-layer high-efficiency catalytic reaction tower through the pipeline, and the water vapor flows from the bottom to the ...

Embodiment 2

[0061] A process system for removing total organic carbon in an emulsion biochemical effluent, including a double-layer high-efficiency catalytic reaction tower, an ozone inlet, a water inlet, a distributor, a bottom catalyst layer, a supported two-component complex molecular sieve catalyst, and intermediate water Layer, top catalytic adsorbent layer, loaded manganese-based activated carbon catalyst, water outlet, gas outlet.

[0062] The biochemical effluent of the emulsion refers to the wastewater treated by the anoxic and aerobic biochemical pools. The pH of the biochemical effluent of the emulsion was 7.5, and the total organic carbon was 49 mg / L.

[0063] The biochemical effluent of the emulsion enters the double-layer high-efficiency catalytic reaction tower from the waste water inlet through the lift pump. Ozone enters the reaction tower from the double-layer high-efficiency catalytic reaction tower through the pipeline, and the water vapor flows from the bottom to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com