Process for firing jun porcelain by aid of temmoku brown golden glaze

A Tianmu sauce, golden technology, applied in the field of ceramic manufacturing, can solve the problems of Jun porcelain glaze easily darkening, low Jun porcelain output, affecting aesthetics and other problems, achieve bright surface, reduce the probability of deformation and cracking, and improve the effect of forming performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

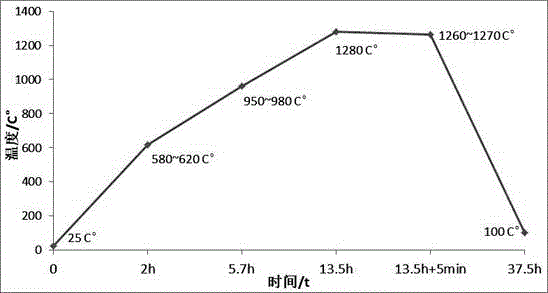

[0038] The process of preparing Jun porcelain using Tianmu sauce gold glaze includes the following steps:

[0039] Step 1. Firing the plain tire

[0040] Mix 65 parts of kaolin, 20 parts of soda stone, 8 parts of Mujie clay and 7 parts of quartz sand evenly, and stir with water at a mass ratio of 1:1 to obtain a mixture; grind the mixture into a slurry with a ball mill, and finely grind it for 80 minutes. The fineness reaches 250 meshes; the obtained mud is hand-drawn to make a plain tire, and the plain tire is put into a kiln to dry at 880°C for 10 hours, and cooled to room temperature with the furnace, and the fired plain tire is obtained. ;

[0041] Step 2. Prepare the glaze

[0042] Mix 22 parts of yellow feldspar, 12 parts of albite, 0.8 part of quartz, 0.6 part of kaolin, 0.5 part of soda stone, 0.8 part of talc, 1.4 parts of bone ash and 0.8 part of iron ore into a ball mill, add water of equal quality to it and ball mill first Make a slurry with a fineness of 350 me...

Embodiment 3

[0048] The process of preparing Jun porcelain using Tianmu sauce gold glaze includes the following steps:

[0049] Step 1. Firing the plain tire

[0050] Mix 65 parts of kaolin, 20 parts of soda stone, 8 parts of Mujie clay and 7 parts of quartz sand evenly, and stir with water at a mass ratio of 1:1 to obtain a mixture; grind the mixture into a slurry with a ball mill, and finely grind it for 80 minutes. The fineness reaches 300 meshes; the obtained mud is hand-drawn to make a plain tire, and the plain tire is put into a kiln to dry at 900°C for 10 hours, and cooled to room temperature with the furnace, and the fired plain tire is obtained. ;

[0051] Step 2. Prepare the glaze

[0052] Mix 26 parts of yellow feldspar, 14 parts of albite, 1 part of quartz, 0.8 part of kaolin, 0.6 part of soda stone, 1 part of talc, 1.6 parts of bone ash and 1 part of iron ore into a ball mill, add water of equal quality to it and ball mill first Make a slurry with a fineness of 350 mesh, th...

Embodiment 4

[0058] The process of preparing Jun porcelain using Tianmu sauce gold glaze includes the following steps:

[0059] Step 1. Firing the plain tire

[0060] Mix 65 parts of kaolin, 20 parts of soda stone, 8 parts of Mujie clay and 7 parts of quartz sand evenly, and stir with water at a mass ratio of 1:1 to obtain a mixture; grind the mixture into a slurry with a ball mill, and finely grind it for 80 minutes. The fineness reaches 250 mesh; the obtained mud is hand-drawn to make a plain tire, and the plain tire is put into a kiln to dry at 930°C for 10 hours, and cooled to room temperature with the furnace, and the fired plain tire is obtained. ;

[0061] Step 2. Prepare the glaze

[0062] Mix 30 parts of yellow feldspar, 16 parts of albite, 1.2 parts of quartz, 1 part of kaolin, 0.7 parts of soda stone, 1.2 parts of talc, 1.8 parts of bone ash and 1.2 parts of iron ore into a ball mill, add water of equal quality to it and ball mill first Form a slurry with a fineness of 350 me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com