Preparation method for polymer microcapsule

A technology of microcapsules and polymers, applied in the field of preparation of polymer microcapsules, can solve the problems of a large number of surfactant initiators, complex systems, etc., and achieve the effects of low cost, simple system and preparation process, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

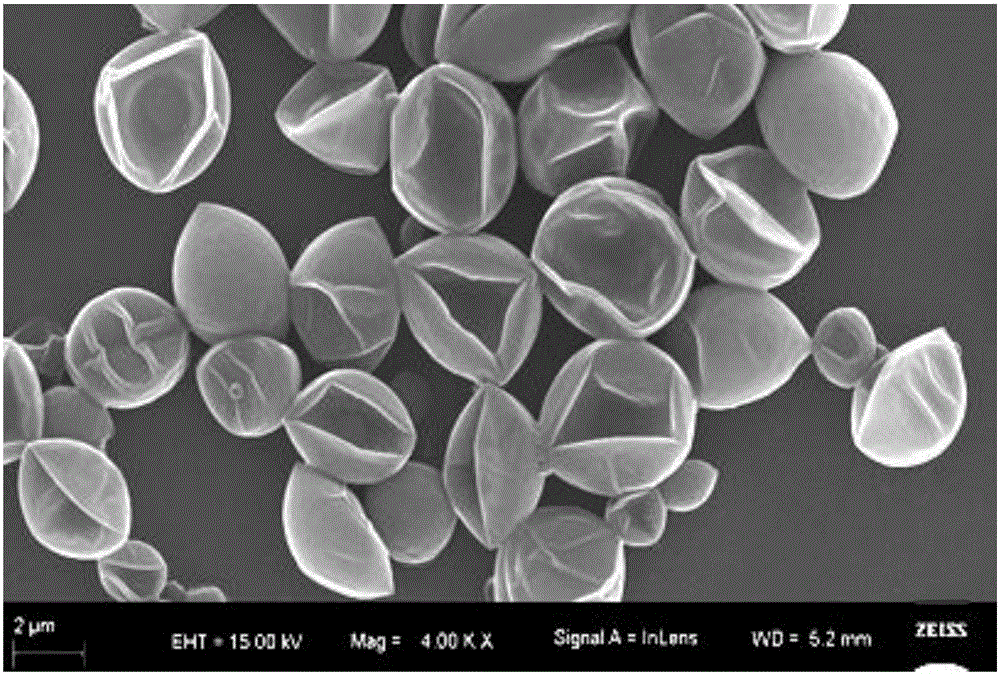

[0018] Embodiment 1: Polyglycidyl methacrylate triggers styrene polymerization to prepare polymer microcapsules

[0019] Mix 6g of polyglycidyl methacrylate, 40g of styrene monomer, and 100g of water, stir and emulsify at room temperature for 10 minutes, heat to 60°C, and react for 12 hours, then fully wash with water to remove unpolymerized styrene and dissolved in Polyglycidyl methacrylate in water to obtain polystyrene microcapsules.

Embodiment 2

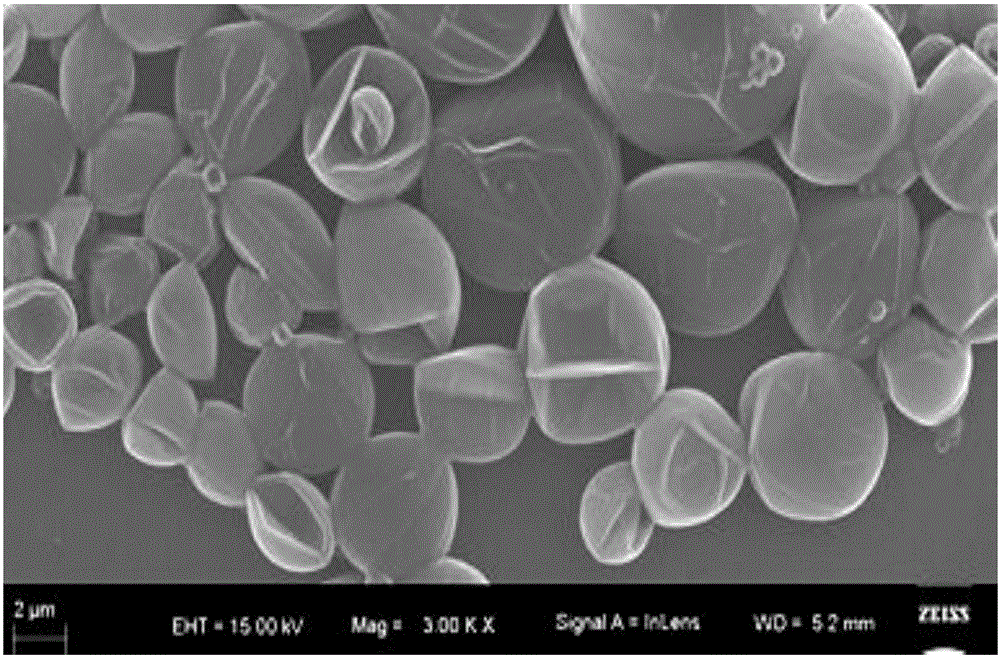

[0020] Example 2: Polyglycidyl methacrylate initiates divinylbenzene polymerization to prepare polymer microcapsules

[0021] Mix 4g of polyglycidyl methacrylate, 40g of divinylbenzene monomer, and 100g of water, stir and emulsify at room temperature for 10 minutes, heat to 70°C, and react for 12 hours, then fully wash with water to remove unpolymerized divinyl Benzene and polyglycidyl methacrylate dissolved in water to obtain polydivinylbenzene microcapsules.

Embodiment 3

[0022] Embodiment 3: Polyglycidyl methacrylate initiates the polymerization of 4-hydroxymethylstyrene to prepare polymer microcapsules

[0023] After mixing 4g polyglycidyl methacrylate, 40g 4-hydroxymethyl styrene monomer, and 100g water, stir and emulsify at room temperature for 30 minutes, heat to 70°C, and react for 12 hours, then fully wash with water to remove unpolymerized 4-hydroxymethylstyrene and polyglycidyl methacrylate dissolved in water to obtain poly(4-hydroxymethylstyrene) microcapsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com