Linear styrene-butadiene block copolymer and preparation method and application thereof

A technology of linear styrene-butadiene block and copolymer, which is applied in the direction of building structure, building components, building insulation materials, etc. It can solve the problems that the high temperature retardation effect cannot be guaranteed, and the low temperature resistance of matrix asphalt cannot be well improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of linear styrene-butadiene block copolymer provided by the invention may further comprise the steps:

[0027] (1) In the presence of an organic monolithium initiator, styrene is carried out in an inert solvent for the first anionic polymerization reaction to obtain a solution containing polystyrene;

[0028] (2) Add an organoaluminum compound to the solution containing polystyrene and mix for 5-10 minutes, then add butadiene to continue the second anionic polymerization reaction to obtain a block polymer containing styrene and butadiene The solution; The organoaluminum complex contains at least one general formula of AlR 1 R 2 R 3 Alkyl aluminum Al 1 and at least one of the general formula AlR 4 R 5 R 6 Alkyl aluminum Al 2 , R 1 , R 2 and R 3 each independently for C 1 -C 4 the alkyl group, R 4 , R 5 and R 6 each independently for C 6 -C 20 Alkyl or C 6 -C 20 the aryl group;

[0029] (3) Add a coupling agent to the solution of...

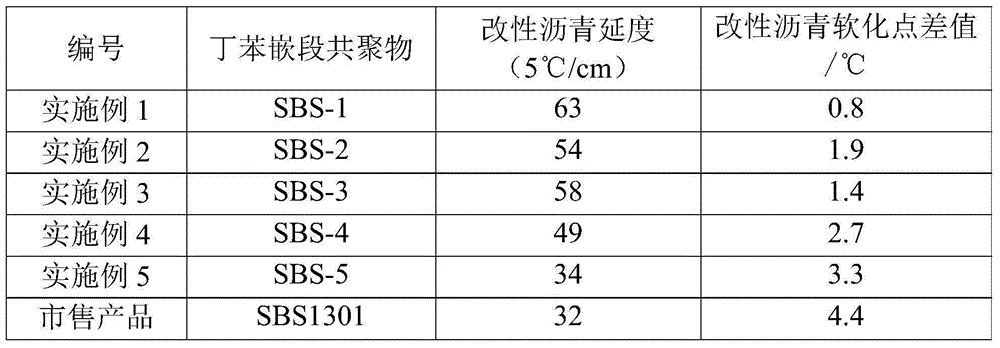

Embodiment 1

[0050] Under the protection of high-purity nitrogen, 1800g of cyclohexane and 230g of styrene were sequentially added to a 5L batch polymerization reactor equipped with an anchor stirrer, stirring was started, and the circulating water bath was heated to 60°C, and then 9ml of n-butylene was added to the reactor Lithium solution (1.6M hexane solution, the same below) initiates the polymerization reaction. After 20min, the styrene stage reaction ends, and 4ml of triisobutylaluminum solution (1.1M hexane solution, the same below) and 17ml triisobutylaluminum solution are added to the reactor. Phenyl aluminum solution (1.0M hexane solution, the same below), add 540g butadiene in the reactor after 10min, after 1h the reaction ends, add 8ml of 1,8-dibromooctane solution (0.5 M cyclohexane solution, the same below), 1ml isopropanol was added after 30min, 6g antioxidant 264 was added after 5min, after stirring evenly, water vapor condensed to remove cyclohexane, dried in a vacuum oven ...

Embodiment 2

[0052] Under the protection of high-purity nitrogen, 1800g of cyclohexane and 255g of styrene were sequentially added to a 5L batch polymerization reactor equipped with an anchor stirrer, stirring was started, and the circulating water bath was heated to 60°C, and then 8ml of n-butylene was added to the reactor Lithium-based solution initiates the polymerization reaction. After 20 minutes, the styrene segment reaction ends. Add 6ml of triisobutylaluminum solution and 8ml of triphenylaluminum solution to the reactor, add 515g of butadiene to the reactor after 10 minutes, and react after 1 hour. At the end, add 10.5ml of 1,8-dibromooctane solution to the reactor, add 1ml of isopropanol after 30 minutes, add 6g of antioxidant 264 after 5 minutes, stir evenly, water vapor condenses to remove cyclohexane, and vacuum oven Dry until the volatile matter is less than 1% by weight to obtain the styrene-butadiene block copolymer SBS-2. The analysis and characterization of the styrene-but...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com