A Tetra package recovered PE/PLA wire used for 3D printing and a preparing method thereof

A 3D printing and Tetra Pak technology, applied in the direction of additive processing, etc., can solve problems such as poor adhesion and achieve the effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

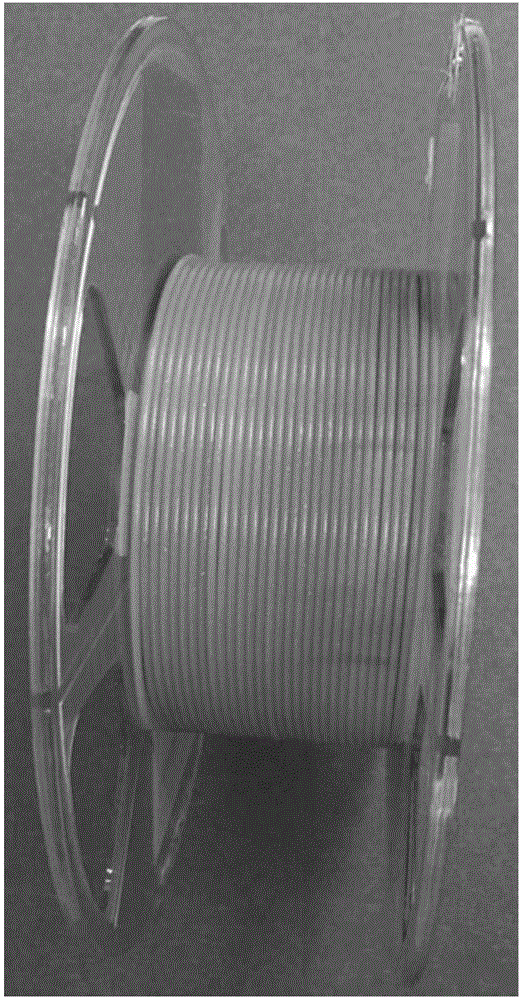

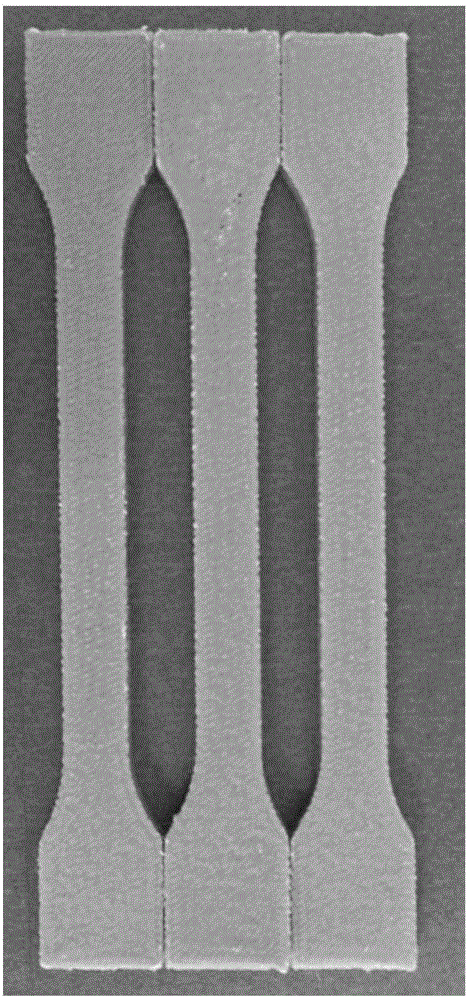

Image

Examples

Embodiment 1

[0039] A Tetra Pak recycled PE / PLA wire for 3D printing, characterized in that:

[0040] (1) the weight percent formula is as follows:

[0041] Tetra Pak Recycled PE 70

[0042] PLA 27

[0043] PE-g-MAH 2

[0044] P990 0.5

[0045] White oil 0.5

[0046] (2) Preparation method:

[0047] A. Put Tetra Pak recycled PE and PLA in a vacuum drying oven to dry;

[0048] B. According to the formula by weight percentage, take by weighing the dried Tetra Pak to recycle PE, PLA, PE-g-MAH, P990 and white oil;

[0049] C. each component after weighing is placed in the high-speed kneader, keep rotating speed 2000 rpm, and stir at high speed for 20min;

[0050] D. Add the uniformly mixed Tetra Pak recycled PE, PLA, PE-g-MAH, P990, and white oil to the feeding port of the screw extruder. The temperature of the screw extruder is 150-210°C, and the speed is 70rpm; The extruded raw material is cooled and sent to the pelletizer to be cut into pellets, and dried for later use;

[0051] E....

Embodiment 2

[0055] A Tetra Pak recycled PE / PLA wire for 3D printing, characterized in that:

[0056] (1) the weight percent formula is as follows:

[0057] Tetra Pak Recycled PE 80

[0058] PLA 13

[0059] POE-g-GMA 5

[0060] FX-5924 1

[0061] white oil 1

[0062] (2) Preparation method:

[0063] A. Put Tetra Pak recycled PE and PLA in a vacuum drying oven to dry;

[0064]B. According to the formula by weight percentage, take by weighing the dried Tetra Pak to recycle PE, PLA, POE-g-GMA, FX-5924 and white oil;

[0065] C. place each component after weighing in the high-speed kneader, keep the rotating speed at 1000-6000 rpm, and stir at high speed for 5-30min;

[0066] D. The uniformly mixed Tetra Pak recycled PE, PLA, POE-g-GMA, FX-5924, and white oil were added to the feeding port of the screw extruder. The temperature of the screw extruder was 150-210 °C, and the rotation speed was 150 rpm; The raw material extruded from the screw is cooled and sent to the pelletizer to be cu...

Embodiment 3

[0071] A Tetra Pak recycled PE / PLA wire for 3D printing, characterized in that:

[0072] (1) the weight percent formula is as follows:

[0073] Tetra Pak Recycled PE 60

[0074] PLA 34.5

[0075] PE-g-GMA 3

[0076] P990 1.5

[0077] white oil 1

[0078] (2) Preparation method:

[0079] A. Put Tetra Pak recycled PE and PLA in a vacuum drying oven to dry;

[0080] B. According to the weight percentage formula, take by weighing the dried Tetra Pak to recycle PE, PLA, PE-g-GMA, P990 and white oil;

[0081] C. place each component after weighing in the high-speed kneader, keep rotating speed 3000 rpm, stir 30min at high speed;

[0082] D. Add the uniformly mixed Tetra Pak recycled PE, PLA, PE-g-GMA, P990 and white oil to the feeding port of the screw extruder. The temperature of the screw extruder is 150-210°C and the speed is 110rpm; The extruded raw material is cooled and sent to the pelletizer to be cut into pellets, and dried for later use;

[0083] E. put the pellet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com