Preparation method of amyl 3-pentyloxy propionate

A technology of pentyloxypentyl propionate and acrylates, which is applied in the field of preparation of 3-pentyloxypentyl propionate, and can solve the problems of many side reactions, products and reactants that cannot be separated in time, and cannot be separated in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] One embodiment of the present invention provides a method for preparing 3-pentyloxypentyl propionate, which includes the following steps 1 to 3.

[0030] Step 1, carry out transesterification reaction and addition reaction with n-amyl alcohol and acrylic acid ester compound under the action of basic catalyst, obtain the product containing 3-amyloxypropionate, and will contain 3-pentoxypropionate The product of pentyl ester is subjected to the first vacuum distillation treatment at -0.02Mpa~-0.06Mpa, 110℃~135℃, and the fraction at 30℃~65℃ is distilled to obtain a mixture of alcohol compounds and acrylate compounds. The liquid is the first crude product containing 3-pentyloxy pentyl propionate, the acrylate compound is any one of methyl acrylate, ethyl acrylate, and butyl acrylate; the alcohol compound is the acrylate compound through transesterification The corresponding alcohol is converted after the reaction.

[0031] It should be noted that in step 1, n-amyl alcohol ...

Embodiment 1

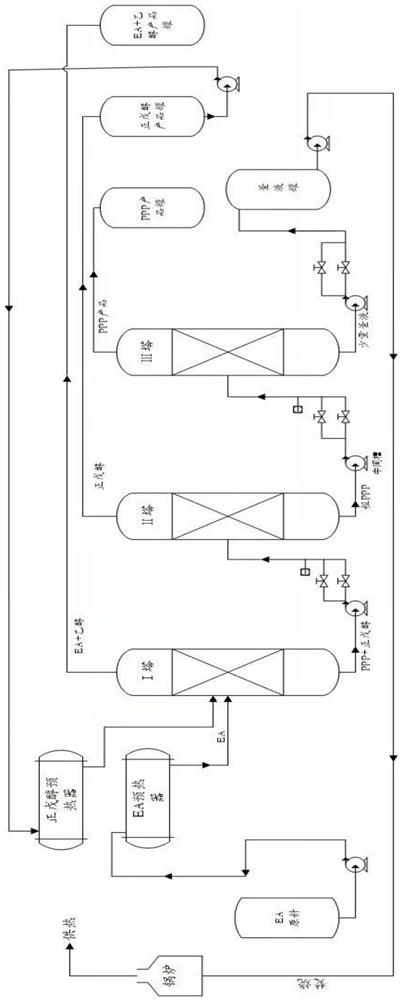

[0074] (1) For details, please refer to figure 1, In a preheater, n-amyl alcohol and the basic catalyst sodium ethoxide were mixed and preheated to 40°C to obtain a mixture; in another preheater, ethyl acrylate was preheated to 40°C. Wherein, based on the total mass of n-amyl alcohol, ethyl acrylate and the basic catalyst, the mass percentage of the basic catalyst is 1%. Then the mixture and ethyl acrylate are simultaneously passed into the middle of the reactive distillation column I for reaction, and the ratio of the amount of n-amyl alcohol to ethyl acrylate is 3:1 by controlling the flow rate. Control the pressure in the reactive distillation I column to -0.035Mpa, the temperature of the tower bottom is 121°C to 126°C, the temperature at the top of the tower is 44°C to 48°C, the reflux ratio at the top of the tower is 4:1, and the number of trays is 41; The by-product ethanol at the boiling point and the unreacted ethyl acrylate are azeotroped, and gradually rise to the t...

Embodiment 2

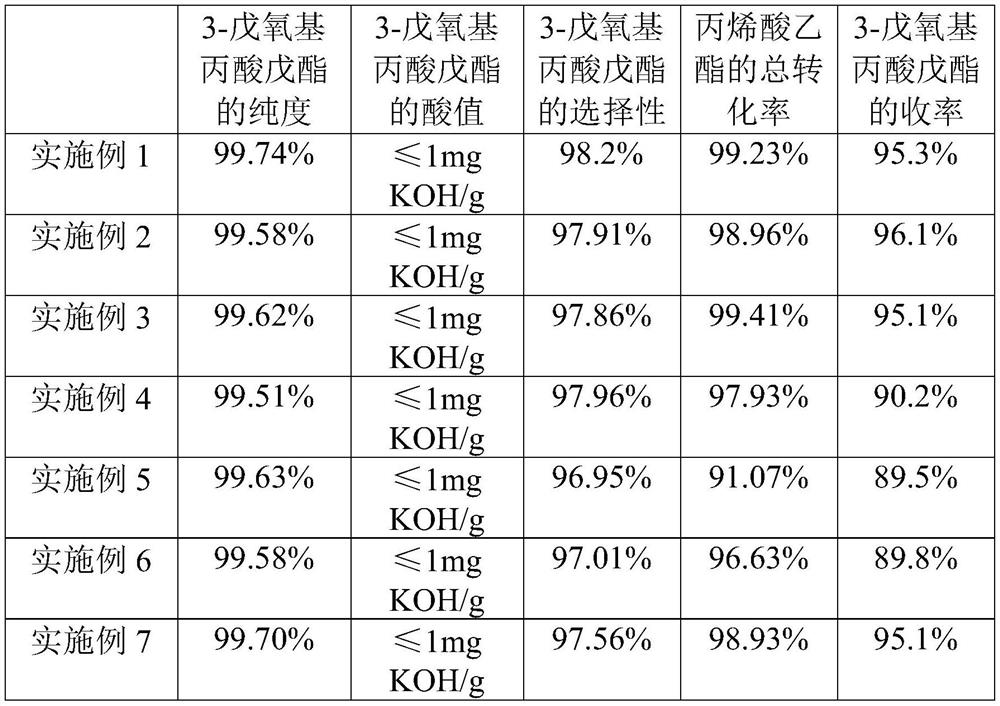

[0091] Embodiment 2 is substantially the same as Embodiment 1, and the difference is only: in step (1), the ratio of the amount of n-amyl alcohol to ethyl acrylate is 2.5: 1; the pressure in the reactive distillation column I is- 0.04Mpa, tower top temperature is 40 ℃~45 ℃; In step (2), the pressure of rectifying tower II is-0.08Mpa, tower still temperature is 159 ℃~169 ℃, tower top temperature is 80 ℃~87 ℃, The reflux ratio is adjusted to 5:1; in step (3), the column pressure of the rectification column III is -0.095Mpa, the reflux ratio is adjusted to 6:1, and the fraction with a top temperature of 141°C to 143°C is collected.

[0092] The remaining steps and process parameters are the same as in Example 1, and the specific results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com