A modified red mud subgrade structure and its construction method

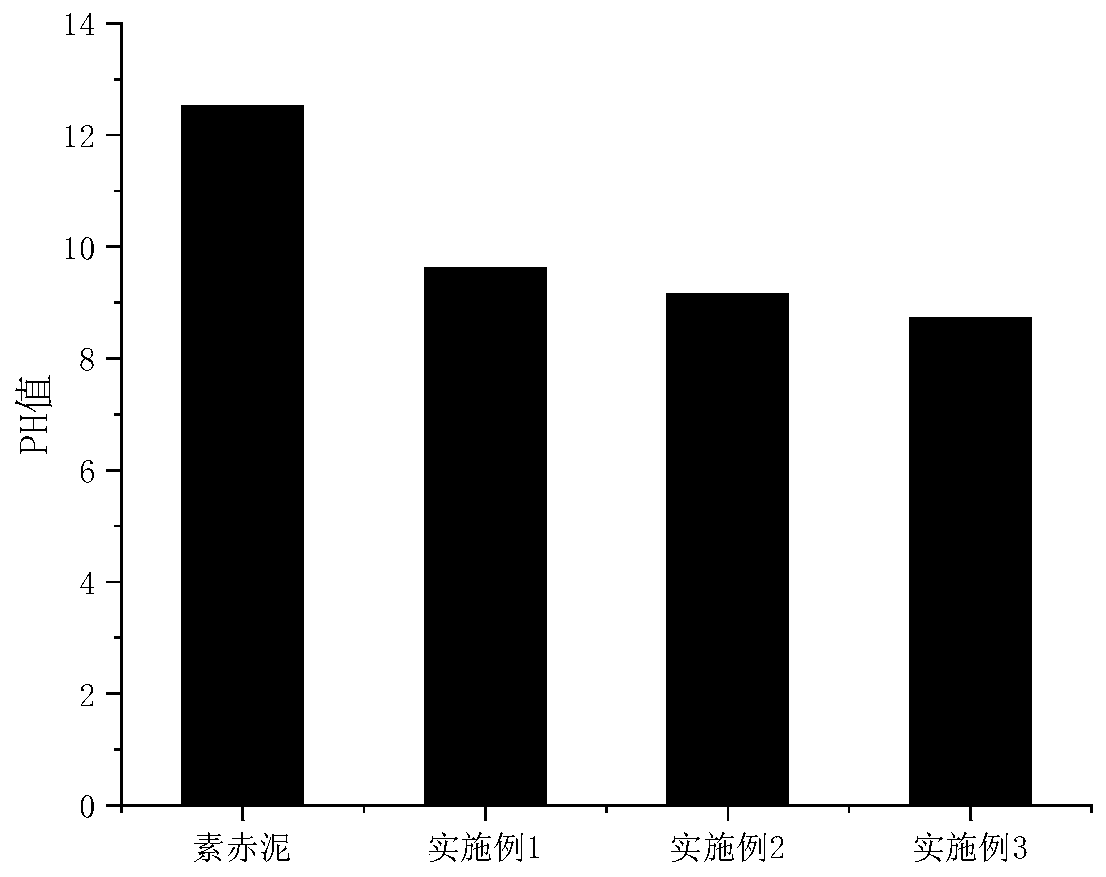

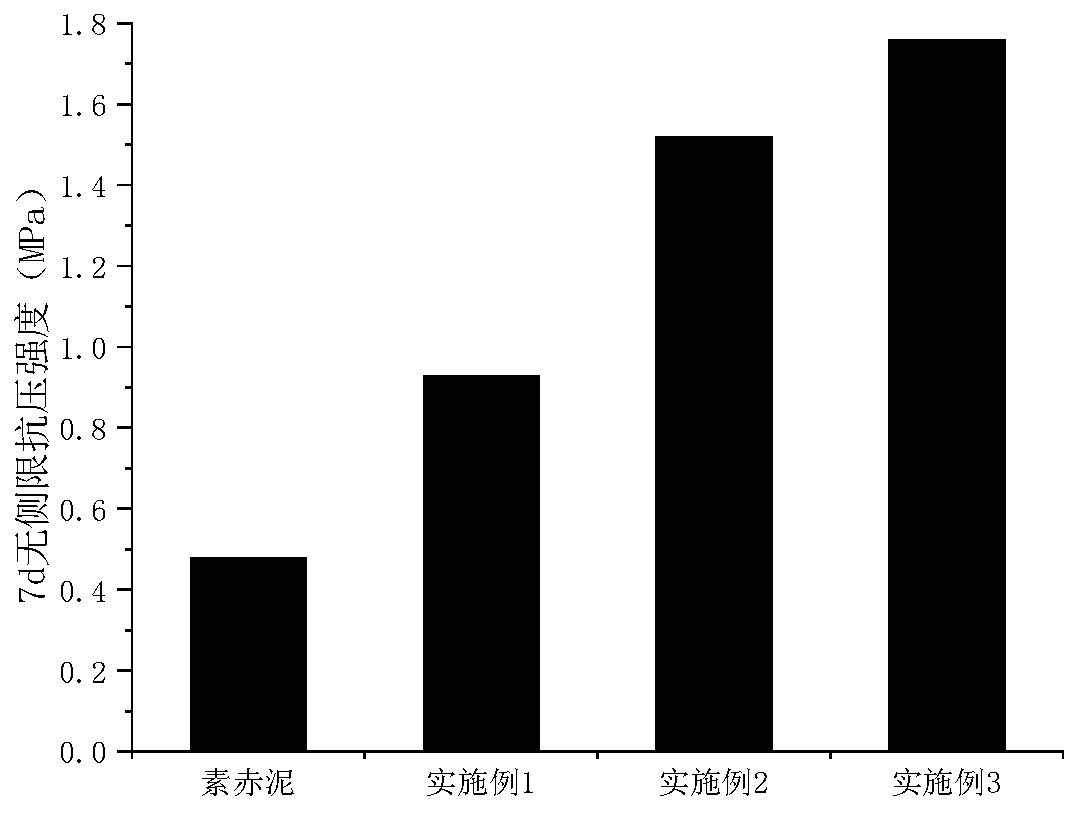

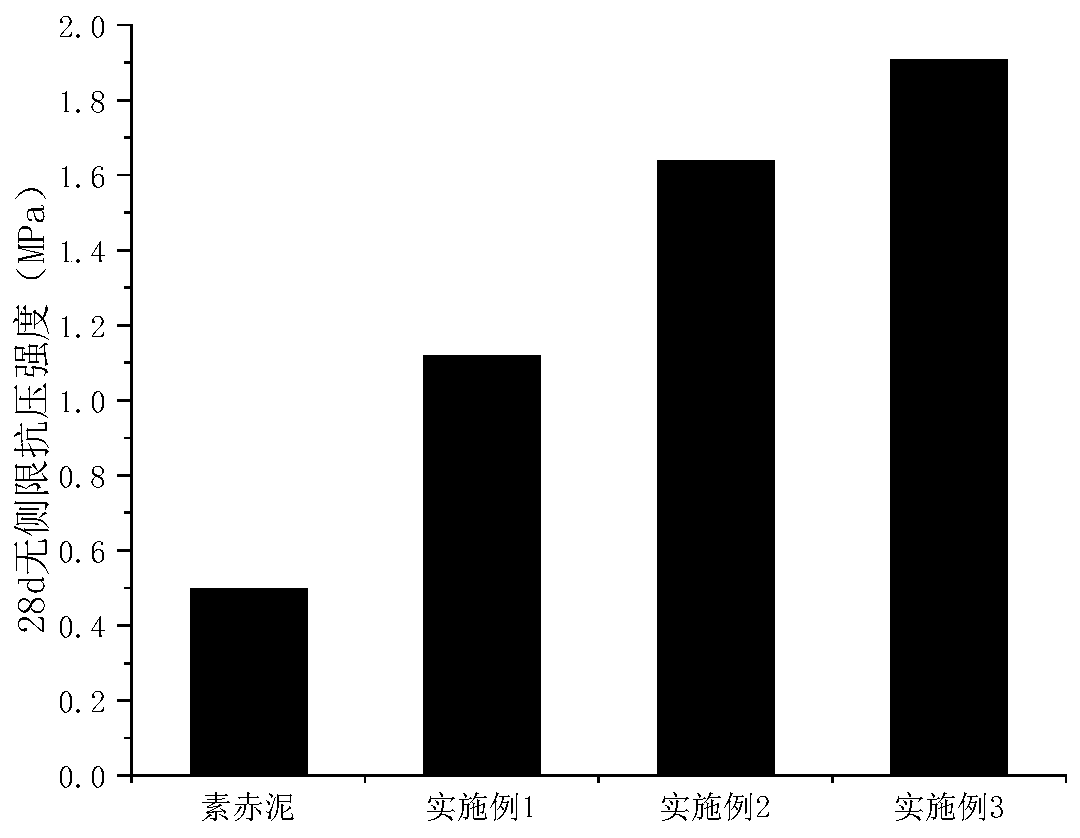

A construction method and technology of red mud road, applied in the field of modified red mud roadbed and its construction, sintering method red mud modifier, can solve the problems of long-term strength attenuation, practical application effect to be verified, etc., to reduce pH value, Achieve green recycling, improve compactness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Preparation and application method of a sintering method red mud road modifier

[0097] 1. Weigh raw materials: including 160 parts of desulfurized gypsum, 80 parts of phosphogypsum, 100 parts of quicklime, and 220 parts of cement.

[0098] 2. Put the weighed raw materials into a clean container and mix them evenly.

[0099] 3. Put the prepared sintered red mud soil samples after air drying and dehydration into the basin, add a modifier accounting for 10% of the dry soil mass, mix them evenly, and divide them into several groups of soil samples.

[0100] 4. Add a certain quality of water to the uniformly mixed soil in step 3, so that the moisture content of the soil sample reaches its optimum moisture content of 42.5%. According to the "Highway Soil Engineering Test Regulations" (JTG E40-2007), according to 96% compaction Make 50mm*50mm cylindrical specimens at a high degree, and keep them healthy for 7d and 28d respectively.

[0101] 5. According to the "Highway Geot...

Embodiment 2

[0103] Preparation and application method of a sintering method red mud road modifier

[0104] 1. Weigh raw materials: including 200 parts of desulfurized gypsum, 80 parts of phosphogypsum, 180 parts of quicklime, and 220 parts of cement.

[0105] 2. Put the weighed raw materials into a clean container and mix them evenly.

[0106] 3. Put the prepared sintered red mud soil samples after air drying and dehydration into pots, add a modifier accounting for 12% of the dry soil mass, mix them evenly, and divide them into several groups of soil samples.

[0107] 4. Add a certain quality of water to the uniformly mixed soil in step 3, so that the moisture content of the soil sample reaches its optimum moisture content of 42.5%. According to the "Highway Soil Engineering Test Regulations" (JTG E40-2007), according to 96% compaction Make 50mm*50mm cylindrical specimens at a high degree, and keep them healthy for 7d and 28d respectively.

[0108] 5. According to the "Highway Geotechni...

Embodiment 3

[0110] Preparation and application method of a sintering method red mud road modifier

[0111] 1. Weigh raw materials: including 160 parts of desulfurized gypsum, 120 parts of phosphogypsum, 100 parts of quicklime, and 320 parts of cement.

[0112] 2. Put the weighed raw materials into a clean container and mix them evenly.

[0113] 3. Put the prepared sintered red mud soil samples after air drying and dehydration into pots, add a modifier accounting for 14% of the dry soil mass, mix them evenly, and divide them into several groups of soil samples.

[0114] 4. Add a certain quality of water to the uniformly mixed soil in step 3, so that the moisture content of the soil sample reaches its optimum moisture content of 42.5%. According to the "Highway Soil Engineering Test Regulations" (JTG E40-2007), according to 96% compaction Make 50mm*50mm cylindrical specimens at a high degree, and keep them healthy for 7d and 28d respectively.

[0115] 5. According to the "Highway Geotechn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com