Packaging bag

A packaging bag and anti-mildew technology, applied in the field of packaging bags, can solve the problems of food dehydration, unfriendly human body and environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

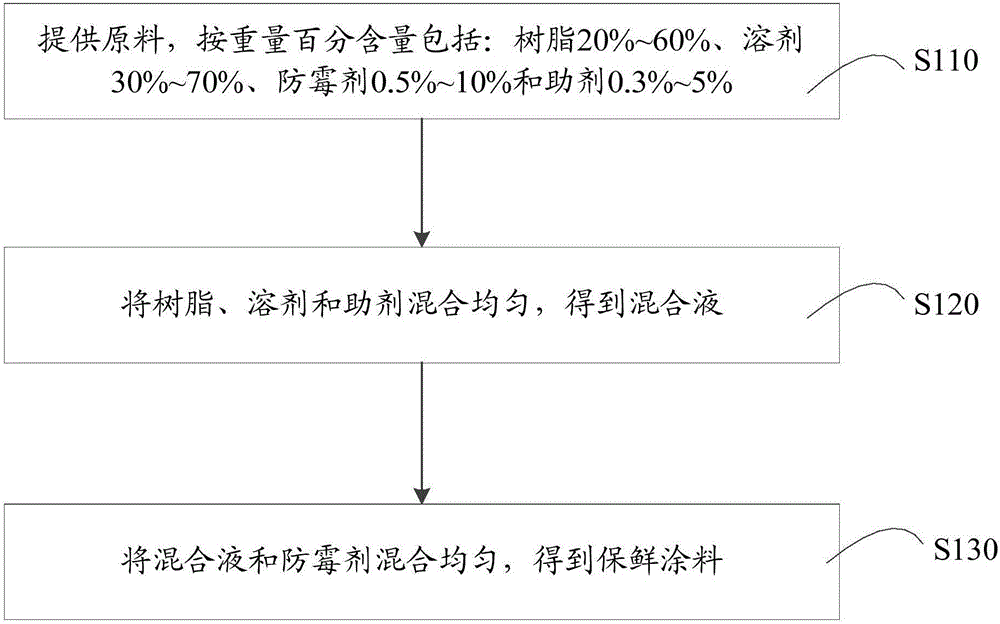

[0038] refer to figure 2 , the preparation method of the above-mentioned mildew-proof and fresh-keeping coating of the present invention, comprises the following steps.

[0039] Step S110: Provide raw materials, including 20%-60% of resin, 30%-70% of solvent, 0.5%-10% of anti-fungal agent and 0.3%-5% of auxiliary agent by weight percentage.

[0040] Step S120: Mix the resin, solvent and additives uniformly to obtain a mixed liquid.

[0041] Specifically, the temperature at which the resin, solvent and additives are mixed in step S120 is 30-65°C.

[0042] Specifically, step S120 includes the following steps: dissolving the resin in a solvent, stirring at a rotation speed of 100-300 rpm and heating to 30-65°C; adding additives, and continuing at a rotation speed of 200-400 rpm Stir for 30-60 minutes to obtain a mixed solution. The temperature and stirring intensity are controlled in this way to promote the uniform mixing of the mixed liquid.

[0043] Specifically, when the ...

Embodiment 1

[0057] The raw materials are provided, and the content by weight percentage includes: 60% of polyurethane resin, 30% of water, 5% of gingerol, 4% of Tween and 1% of triethylamine.

[0058] Dissolve the polyurethane resin in water, stir at a speed of 300 rpm and heat to 50°C; add additives, and continue stirring for 50 min at a speed of 300 rpm to obtain a mixed solution. The pH of the mixture was 7 after adding triethylamine.

[0059] Gingerol is added dropwise to the mixed solution with stirring at a speed of 600 rpm. After the addition of gingerol is completed, the mixed solution and gingerol are continuously stirred and mixed at a speed of 600 rpm. Cool down to obtain the anti-mildew and fresh-keeping coating.

[0060] The anti-mold and fresh-keeping coating is coated on the substrate, and then treated at 80°C, 90°C, 120°C, 100°C and 85°C for 1.2s respectively to obtain the anti-mold and fresh-keeping coating.

Embodiment 2

[0062] Raw materials are provided, including by weight percentage: 47% of polyvinyl alcohol 2488 resin, 40% of water, 8% of the total amount of sorbic acid and turmeric alcohol, 2% of Tween and 3% of sodium bicarbonate.

[0063] Dissolve polyvinyl alcohol 2488 resin in water, stir at a speed of 100 rpm and heat to 65°C; add additives, and continue stirring for 30 minutes at a speed of 200 rpm to obtain a mixed solution. The pH of the mixture was 8 after adding sodium bicarbonate.

[0064] Sorbic acid and turmeric alcohol are added dropwise under the stirring of 800 rev / mins with rotating speed in mixed solution, after sorbic acid and turmeric alcohol dropwise are finished, mixed solution, sorbic acid and turmeric alcohol are continued to rotate at a speed of 800 rpm. Stir and mix for 2 hours at 500-800 rpm. Cool down to obtain the anti-mildew and fresh-keeping coating.

[0065] The anti-mildew and fresh-keeping coating is coated on the substrate, and then treated at 85°C, 95...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com