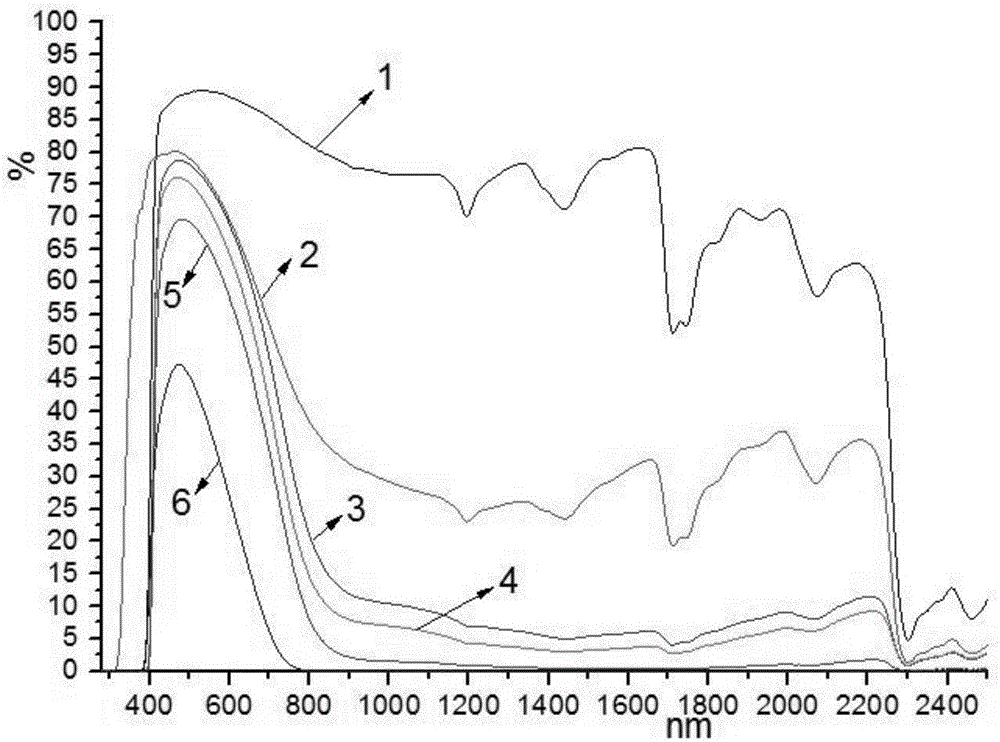

High thermal-insulating eye and skin protecting type PVB film and production method thereof

A film and formula technology, applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problems of PVB film discoloration and infrared blocking, and achieve strong market promotion and application prospects, transparent The effect of good light rate and optimized production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

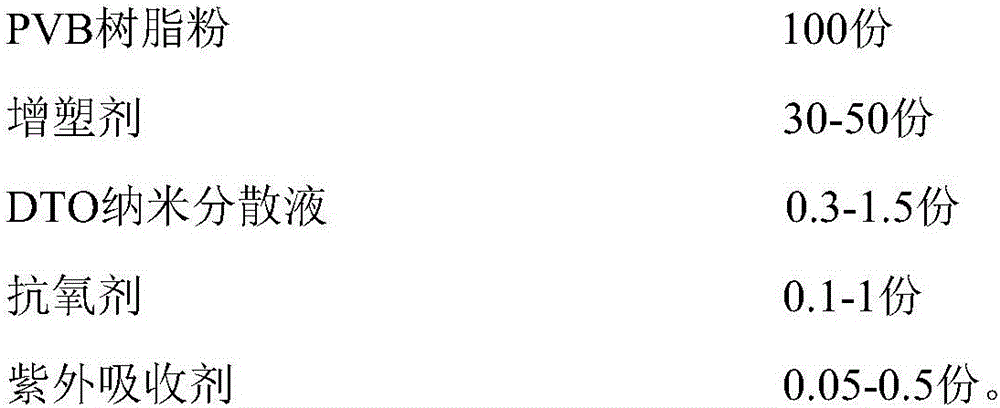

Method used

Image

Examples

Embodiment 1

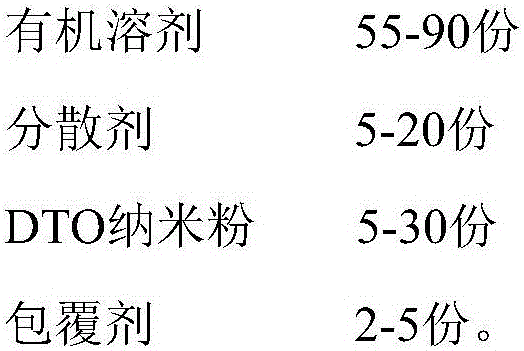

[0042] (1) Preparation of nano-DTO dispersion

[0043] Take 7.8kg of dispersing medium isopropanol and 1kg of nano-DTO powder, mix them together, carry out rough grinding on a ball mill for 3-5 hours, then add 1kg of dispersant silane coupling agent 6598 and 0.2kg of coating agent (11 -acryloyloxyundecyl)phosphonic acid, and then continue to grind on a ball mill for 4-7 days to prepare a nano DTO dispersion.

[0044] (2) 100kgPVB resin powder, 0.4kg antioxidant mixture (by 266.8g tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester and 133.2g three [2, 4-di-tert-butylphenyl]phosphite), 0.1kg UV absorber mixture (composed of 50g 2-(2'-hydroxy-5'-tert-octyl)-benzotriazole and 50g2-(2'-hydroxy- 5'-methyl)-benzotriazole), added to the powder mixer, and stirred at a high speed of 1000RPM for 20 minutes. Control the temperature of the equipment so that the temperature of the material during the stirring process is between 40°C and 50°C. Finally, 3...

Embodiment 2

[0046] (1) Preparation of nano-DTO dispersion

[0047] Take 8.2kg of dispersing medium isopropanol and 1.2kg of nano-DTO powder, mix them together, carry out coarse grinding on a ball mill for 3-5 hours, then add 0.4kg of dispersant silane coupling agent 6598 and 0.2kg of coating agent (11-acryloyloxyundecyl)phosphonic acid, and then continue to grind on a ball mill for 4-7 days to prepare a nano-DTO dispersion.

[0048] (2) 100kgPVB resin powder, 0.4kg antioxidant mixture (by 266.8g tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester and 133.2g three [2, 4-di-tert-butylphenyl]phosphite), 0.1kg UV absorber mixture (composed of 50g 2-(2'-hydroxy-5'-tert-octyl)-benzotriazole and 50g2-(2'-hydroxy- 5'-methyl)-benzotriazole), added to the powder mixer, and stirred at a high speed of 1000RPM for 20 minutes. Control the temperature of the equipment so that the temperature of the material during the stirring process is between 40°C and 50°C. Finall...

Embodiment 3

[0050] (1) Preparation of nano-DTO dispersion

[0051] Take 7.6kg of dispersing medium isopropanol and 1.2kg of nano-DTO powder, mix them together, carry out rough grinding on a ball mill for 3-5 hours, then add 1kg of dispersant silane coupling agent 6598 and 0.2kg of coating agent ( 11-acryloyloxyundecyl)phosphonic acid, and then continue to grind on a ball mill for 4-7 days to obtain a nano-DTO dispersion.

[0052] (2) 100kgPVB resin powder, 0.4kg antioxidant mixture (by 266.8g tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester and 133.2g three [2, 4-di-tert-butylphenyl]phosphite), 0.1kg UV absorber mixture (composed of 50g 2-(2'-hydroxy-5'-tert-octyl)-benzotriazole and 50g2-(2'-hydroxy- 5'-methyl)-benzotriazole), added to the powder mixer, and stirred at a high speed of 1000RPM for 20 minutes. Control the temperature of the equipment so that the temperature of the material during the stirring process is between 40°C and 50°C. Finally, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com