Combined centrifugal compressor for continuous catalytic reforming units

A centrifugal compressor and reformer technology, which is applied in the petroleum industry, processing naphtha, etc., can solve problems such as insufficiency, and achieve the effects of reducing design and production costs, shortening production cycles, and reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1120

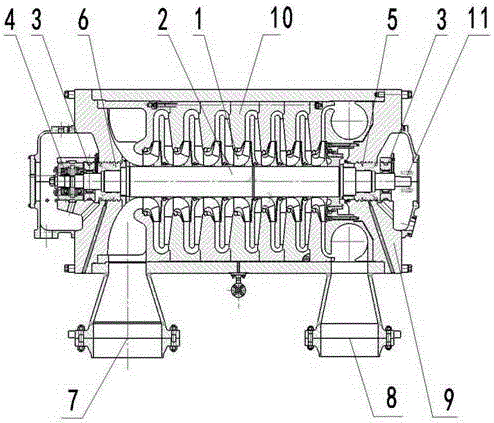

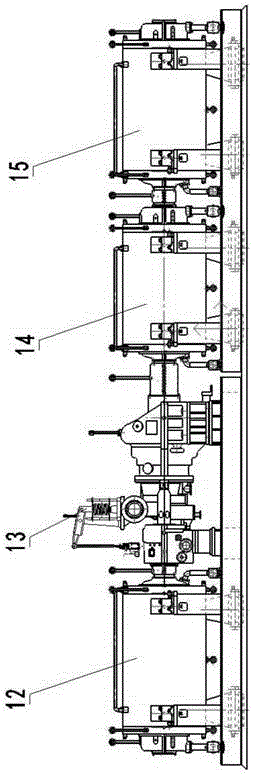

[0023] Example 1 Combined centrifugal compressor for 1.2 million tons / year continuous reforming unit

[0024] 1.2 million tons / year high-pressure cylinder centrifugal compressor for continuous reforming, adopts vertical split form, and the seven impellers are all closed impellers with an outer diameter of 700mm. There are shaft end seals, dry gas seals and other structures. The compression ratio of the whole machine is 1.73.

[0025] 1.2 million tons / year medium-pressure cylinder centrifugal compressor for continuous reforming, adopts vertical split form, and the seven impellers are all closed impellers with an outer diameter of 700mm. Equipped with shaft end seal, dry gas seal and other structures. The compression ratio of the whole machine is 2.01.

[0026] 1.2 million tons / year low-pressure cylinder centrifugal compressor for continuous reforming, adopts vertical split form, and the seven impellers are closed impellers with an outer diameter of 700mm. There are shaft en...

Embodiment 2

[0027] Example 2 Centrifugal compressor for 1 million tons / year continuous reforming unit

[0028] The high-pressure cylinder of the centrifugal compressor for 1 million tons / year continuous reforming is vertically split, and the seven impellers are all closed impellers with an outer diameter of 700mm. There are shaft end seals, dry gas seals and other structures. A compression ratio of 1.73 was achieved.

[0029] The medium-pressure cylinder of a centrifugal compressor for continuous reforming of 1 million tons per year adopts a vertically split form, and the seven impellers are all closed impellers with an outer diameter of 700mm. Equipped with shaft end seal, dry gas seal and other structures. The compression ratio of the whole machine is 2.01.

[0030] The low-pressure cylinder of the centrifugal compressor for 1 million tons / year continuous reforming is vertically split, and the seven impellers are all closed impellers with an outer diameter of 700mm. There are shaft ...

Embodiment 3

[0031] Example 3 Centrifugal compressor for 1.5 million tons / year continuous reforming unit

[0032] The high-pressure cylinder of the centrifugal compressor for 1.5 million tons / year continuous reforming is vertically split, and the ten impellers are all closed impellers with an outer diameter of 400mm. There are shaft end seals, dry gas seals and other structures. The compression ratio of the whole machine is 1.73.

[0033] The medium-pressure cylinder of the centrifugal compressor for 1.5 million tons / year continuous reforming is vertically split, and the seven impellers are all closed impellers with an outer diameter of 400mm. Equipped with shaft end seal, dry gas seal and other structures. The compression ratio of the whole machine is 2.01.

[0034] The low-pressure cylinder of the centrifugal compressor for 1.5 million tons / year continuous reforming is vertically split, and the eight impellers are all closed impellers with an outer diameter of 400mm. There are shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com