Electric heating device with plasma-sprayed stainless steel tube

A technology of stainless steel pipe and plasma, applied in the direction of coating, fusion spraying, metal material coating process, etc., can solve the problems of difficult control of product defects, limited range of material selection, difficult performance improvement, etc., to achieve high production efficiency and product quality Good stability and reliability, strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described below in conjunction with specific embodiments.

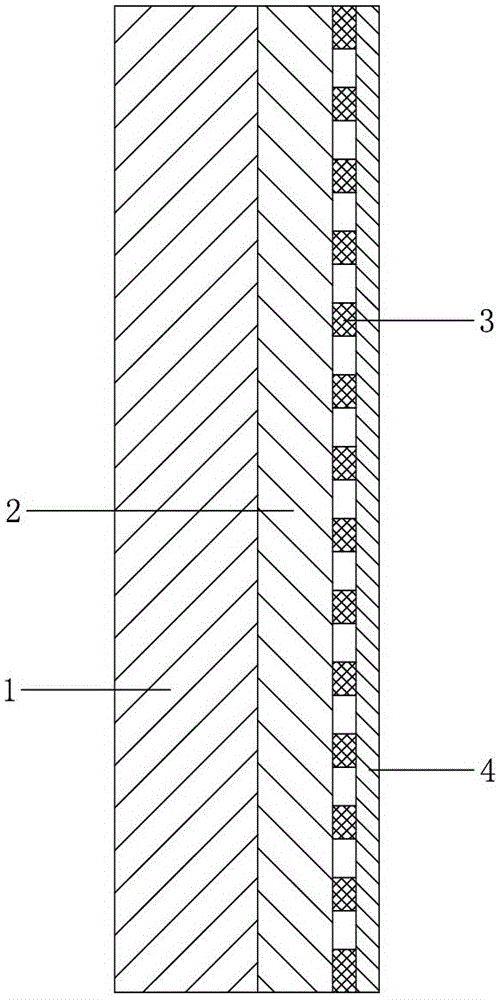

[0023] Such as figure 1 As shown, a plasma sprayed stainless steel tube electric heating device includes a stainless steel tube 1 in the shape of a round tube. The outer peripheral surface of the stainless steel tube 1 is sprayed with a dielectric layer 2 by plasma spraying, and the outer surface of the dielectric layer 2 is sprayed by plasma spraying. A resistance layer 3 is sprayed, the outer surface of the resistance layer 3 is sprayed with an encapsulation layer 4 by means of plasma spraying, and the resistance layer 3 is provided with electrodes exposed to the encapsulation layer 4;

[0024] The dielectric layer 2 is a ceramic powder layer or a glass powder layer;

[0025] The resistance layer 3 is a molybdenum powder layer, niobium powder layer, nickel powder layer, molybdenum alloy powder layer, niobium alloy powder layer or nickel alloy powder layer;

[0026] The packagin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com