Intelligent remote control self-adaption pipe robot

A pipeline robot and intelligent remote control technology, which is applied in the direction of special pipes, pipe components, mechanical equipment, etc., can solve the problems of complex overall structure and driving principle of pipeline robots, limited flexibility and range of motion of mechanisms, and failure of pipelines to achieve self-adaptation. Achieve high pipe passing performance and stability, excellent bending performance and stability, and reduce complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

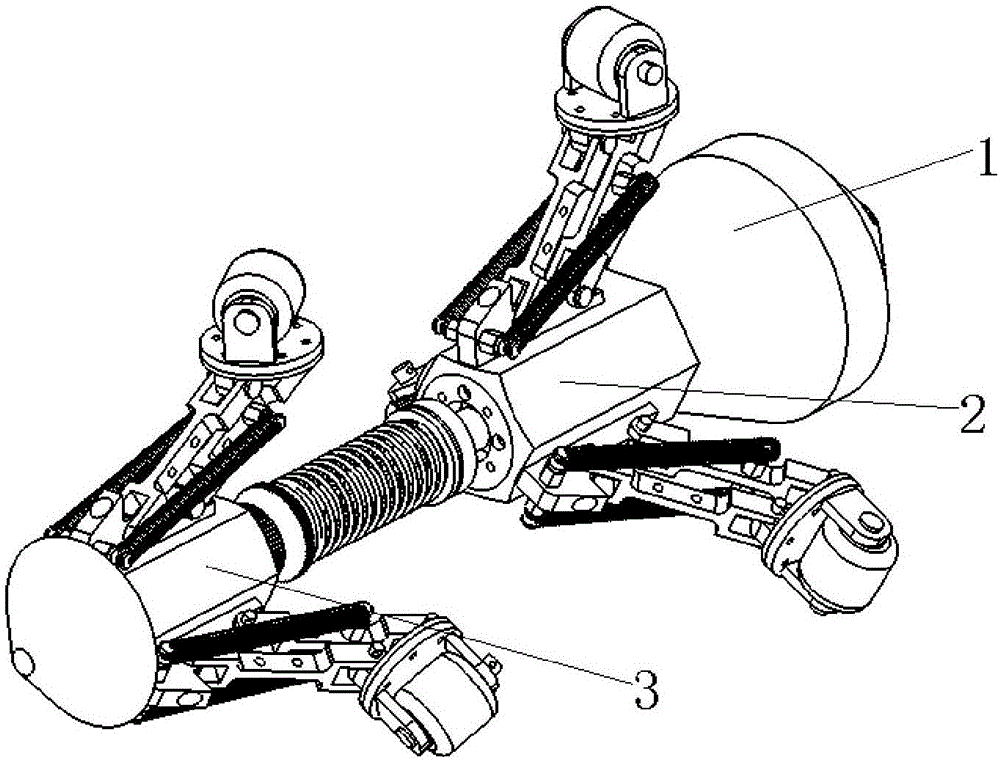

[0030] like Figure 1-10 As shown, the present invention provides an intelligent remote control adaptive pipeline robot, including: a control guide assembly 1 , a universal transmission assembly 3 and six adaptive adjustment bracket assemblies 2 .

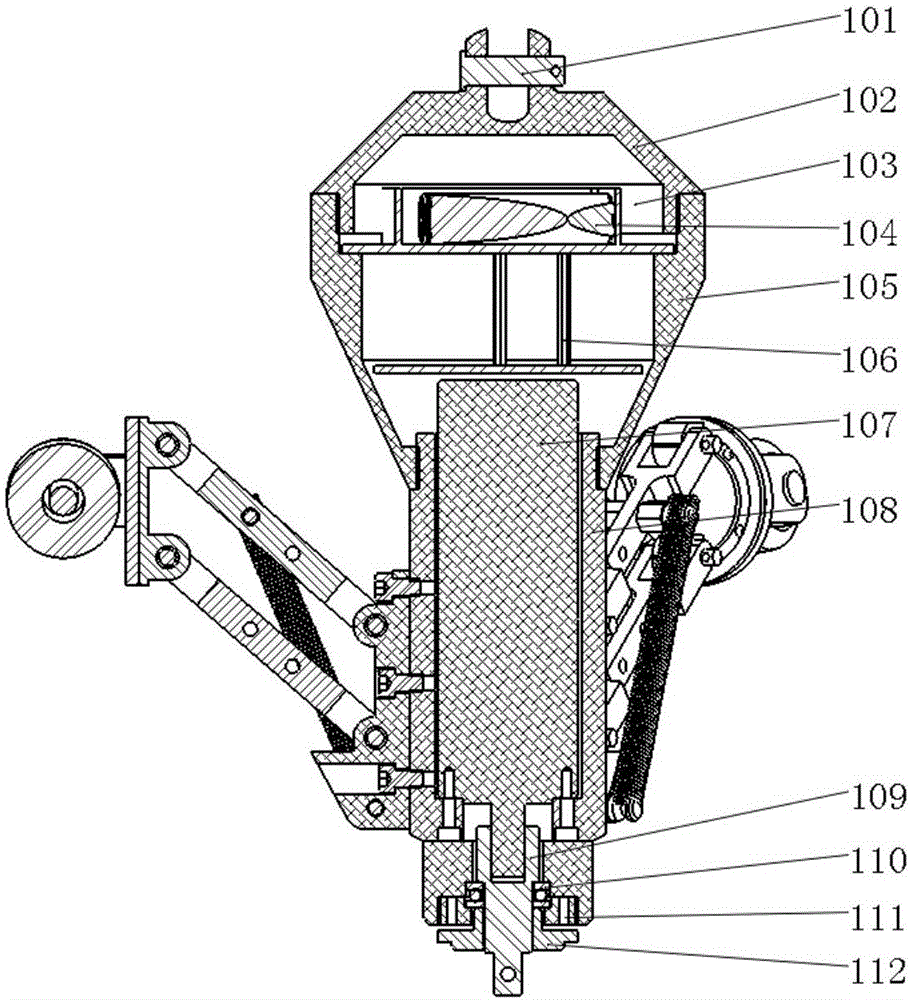

[0031] The control guide assembly 1 includes a traction pin shaft 101 , a traction housing 102 , a battery box 103 , a battery pack 104 , a conical adapter housing 105 , a circuit board 106 , a gear motor 107 , a gear motor mounting housing 108 , and a transmission stepped shaft 109 , rolling bearing 110 , bearing retaining ring 111 and nylon block 112 .

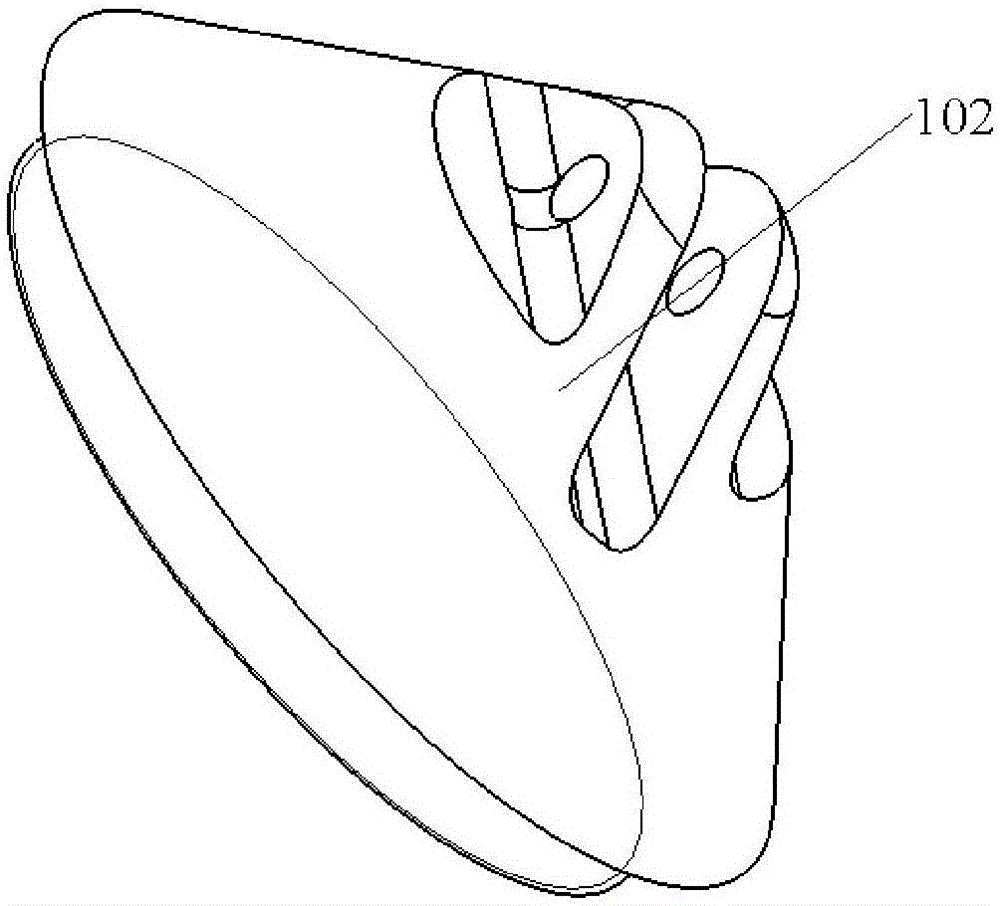

[0032] The main body of the traction housing 102 is in the shape of a cone, the interior is a cavity, and two symmetrical lugs are provided on the top, a through hole is provided on the two lugs, and a space for installing an external pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com