Heating electric furnace with medium-frequency control touch screen

A technology for heating electric furnaces and touch screens, which is applied in lighting and heating equipment, furnaces, crucible furnaces, etc. It can solve the problems that the current size and temperature cannot be displayed intuitively, the automation equipment cannot be intelligently networked, and the level of automation is low. The interaction is simple and intuitive, the effect of lowering the temperature and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

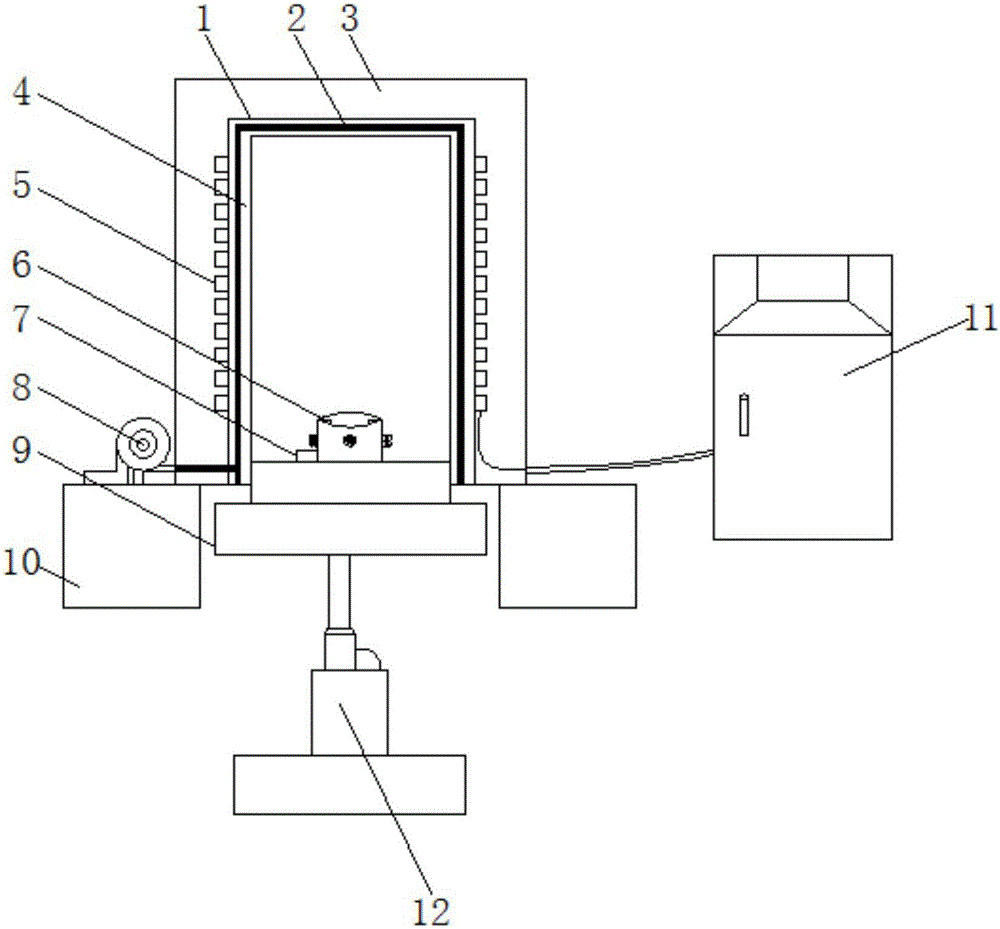

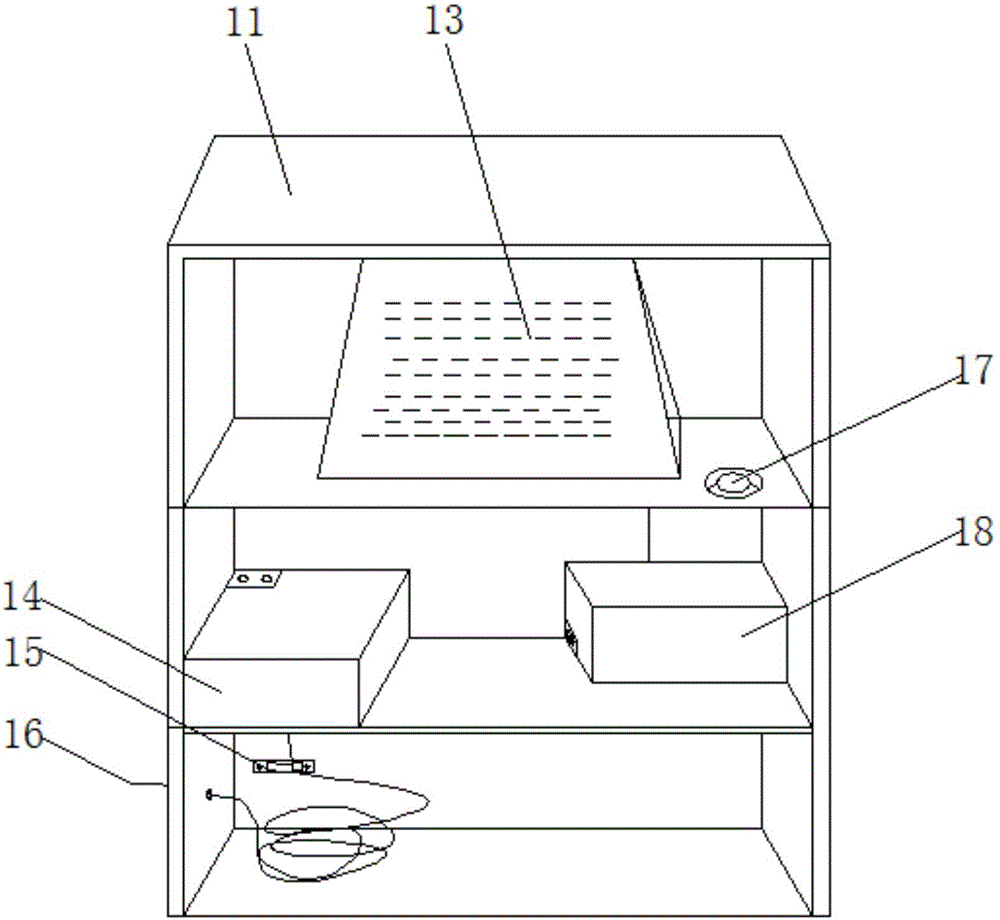

[0016] see Figure 1-2 , the present invention provides a technical solution: a heating electric furnace with an intermediate frequency control touch screen, including a furnace body 3 and a control cabinet 11, a safety lining 1 is arranged inside the furnace body 3, and a coil 5 is fixed on the outer surface of the safety lining 1, A cooling water pipe 2 is installed between the safety lining 1 and the dry material layer 4, and the dry material layer 4 is set inside the safety lining 1, and the lower end of the furnace body 3 is provided with a lower end cover 9, and the lower end cover 9 is fixed on the hydraulic device The upper surface of the piston rod in 12, the upper surface of the lower end cover 9 are equipped with a clamp 6 and a temperature sensor 7, the furnace body 3 is fixed on the upper surface of the base 10, and the water outlet of the dual-power water pump 8 installed on the upper surface of the base 10 The water inlet of the cooling water pipe 2 is sealed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com