Electric lifting table initial height recognition method

A technology of initial height and identification method, applied in the direction of sound wave re-radiation, radio wave measurement system, and utilization of re-radiation, etc., can solve problems such as safety, hidden danger, loss of motor or electrical components, etc., and achieve safe operation and energy consumption. Low and high detection of accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

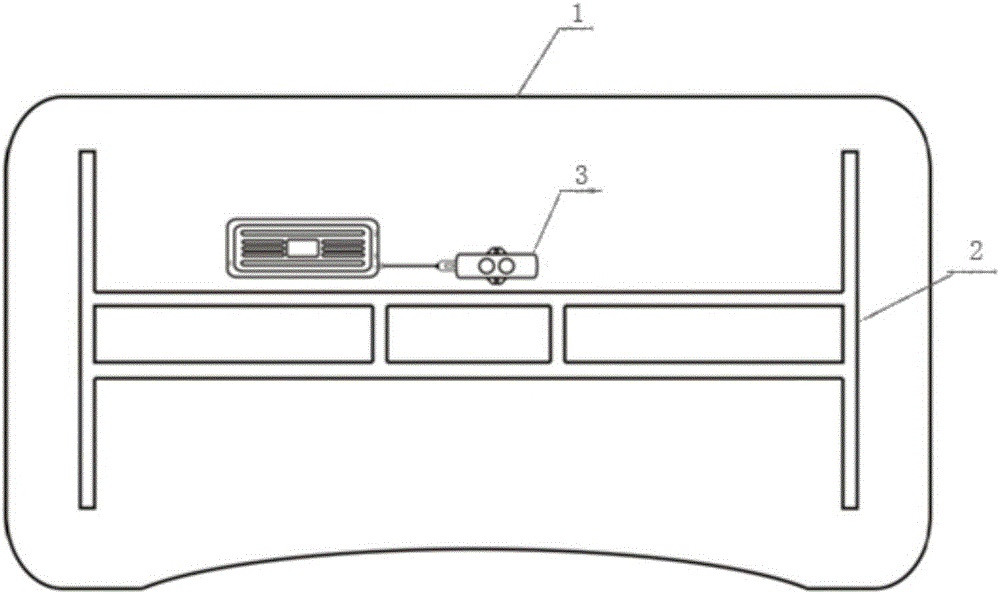

[0038] Such as figure 1 As shown, an electric lifting table includes a table plate 1, a lifting column 2 driving the lifting of the table plate 1, and a control system for lifting and controlling the lifting column 2. The electric lifting table is equipped with an ultrasonic rangefinder 3, which Both the ranger 3 and the control system are equipped with a single-chip microcomputer. The ultrasonic range finder 3 is connected to the control system, which means that the single-chip microcomputer in the ultrasonic range finder 3 communicates with the single-chip microcomputer in the control system through a communication protocol. In this embodiment, the ultrasonic rangefinder 3 is installed on the lower bottom surface of the table top 1, and the test port of the ultrasonic rangefinder 3 faces the bottom surface. The ultrasonic rangefinder 3 emits ultrasonic waves from the test port to the ground and receives reflected waves, thereby Get the current height of the desk.

[0039] Such ...

Embodiment 2

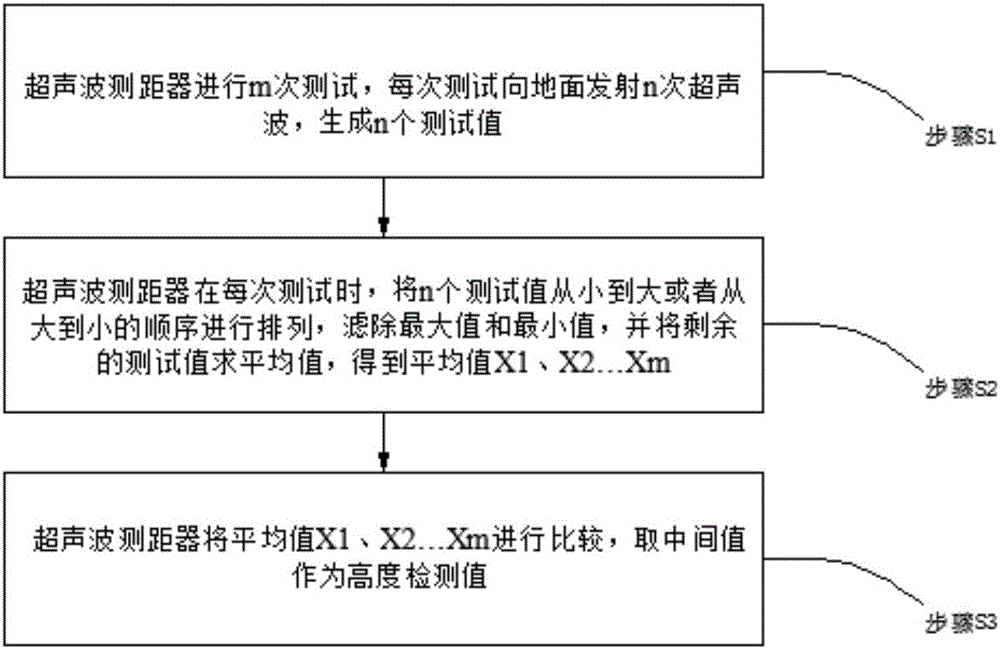

[0060] Such as Figure 4 As shown, this embodiment provides another numerical screening method in step 4, which includes the following steps:

[0061] Step S1: the ultrasonic range finder performs m tests to generate m test values;

[0062] Step S2: The ultrasonic rangefinder averages the m test values to obtain the height detection value.

[0063] Compared with the numerical filtering method provided in the first embodiment, the numerical filtering method provided in this embodiment has a simpler processing process of numerical filtering, and the single-chip computer in the ultrasonic rangefinder takes less time to calculate, so it can be completed more quickly The numerical screening of the height test value obtains the height detection value, which further shortens the time for the initial height recognition of the electric lift table.

Embodiment 3

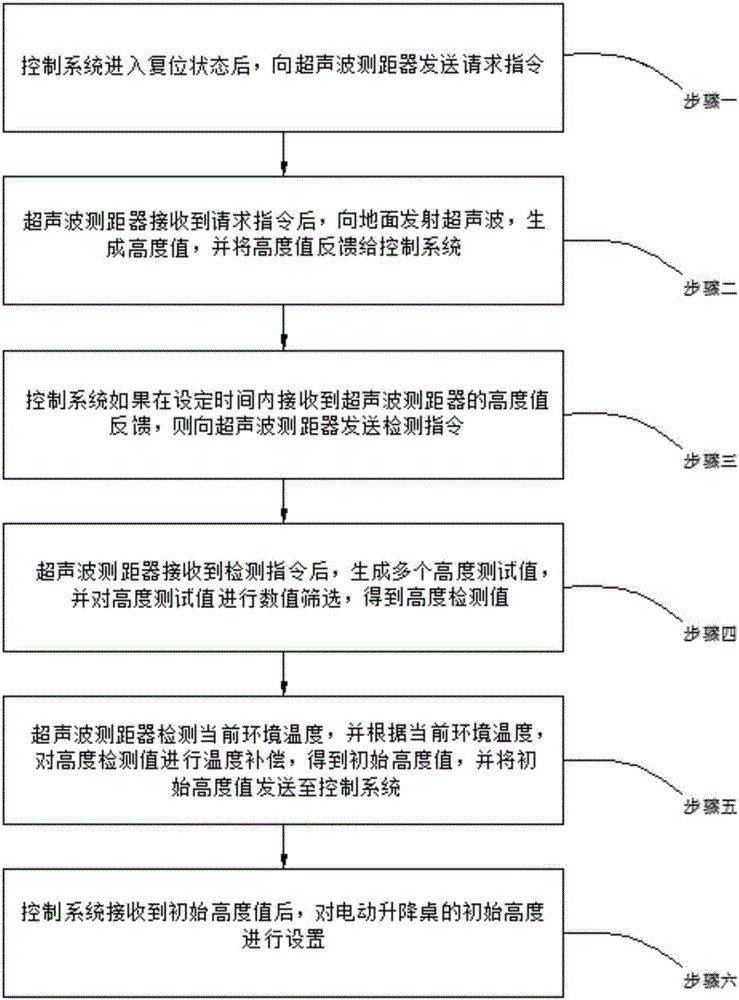

[0065] Such as Figure 5 As shown, this embodiment provides another method for identifying the initial height of an electric lift table, which includes the following steps:

[0066] Step 1: After the control system enters the reset state, it sends a request instruction to the ultrasonic rangefinder;

[0067] Step 2: After receiving the request instruction, the ultrasonic rangefinder transmits ultrasonic waves to the ground to generate a height value, and feed back the height value to the control system;

[0068] Step 7: If the control system does not receive the height feedback of the ultrasonic rangefinder within the set time, it controls the electric lift table to run to the lowest or highest point;

[0069] Step 8: Obtain the position information of the electric lift table through the sensor or limit switch set on the electric lift table, and send the position information to the control system;

[0070] Step 9: After receiving the position information, the control system sets the ini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com