Method for accurately selecting diameters of steel rods of rod mills

A technology for selecting rods and steel rods, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve universal and targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

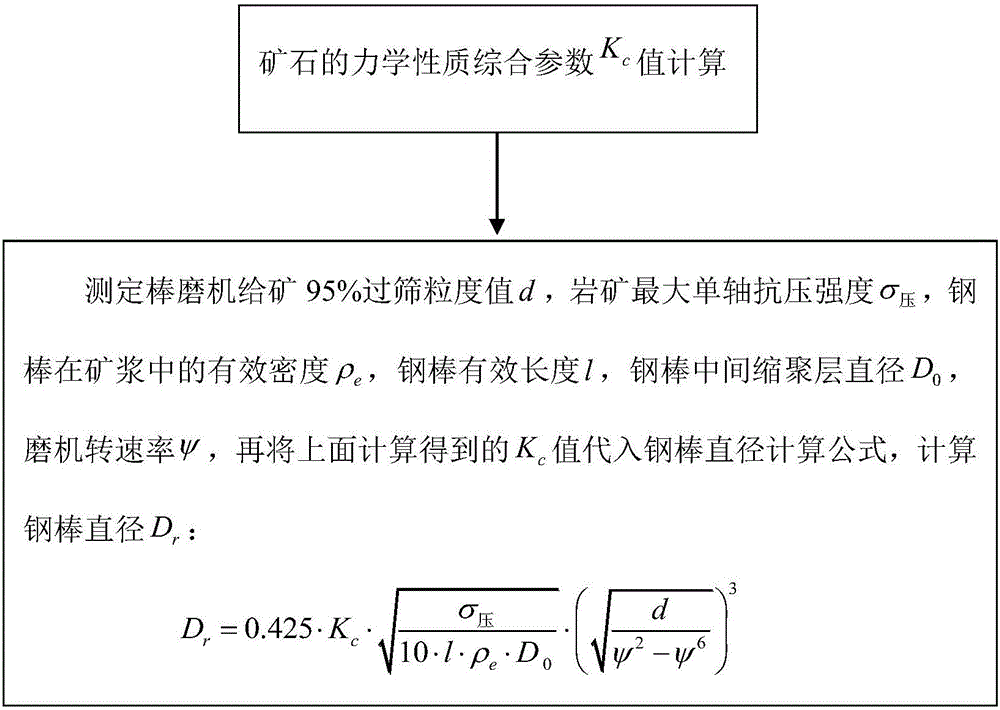

[0040] A method to accurately select the rod diameter of the rod mill, such as figure 1 As shown, the specific steps are as follows:

[0041] The ore to be processed is the alumina ore of Chalco Henan Zhengzhou Alumina Plant, and the size of the rod mill is 3.6×5.0 meters.

[0042] (1) Determination of comprehensive parameters of mechanical properties of ore:

[0043] Select 15 representative ores whose length, width and height are greater than 20cm before coarse crushing, and measure the secant Poisson's ratio of each ore on the material testing machine after making a standard test piece, which are: 0.250, 0.305, 0.265, 0.311, 0.303, 0.266, 0.321, 0.241, 0.202, 0.262, 0.322, 0.243, 0.232, 0.246, 0.288. According to the average secant Poisson's ratio value of 0.27, the comprehensive parameter K of the mechanical properties of the ore is calculated. c is 1.23.

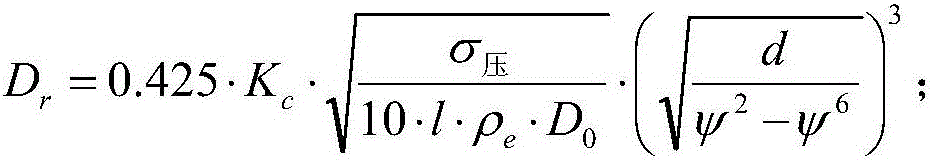

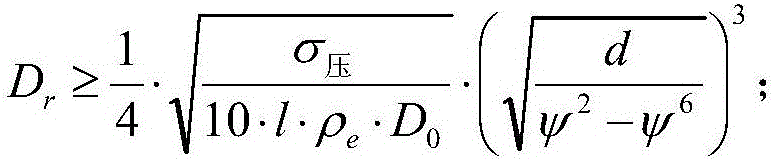

[0044] (2) Determination of steel rod diameter:

[0045] Determine the 95% sieving particle size value d of rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com