Method for making and using a test sample for measuring the length of a lightly doped drain region

A technology of lightly doped drain region and test sample, applied in semiconductor/solid-state device testing/measurement, semiconductor/solid-state device manufacturing, semiconductor device, etc., can solve the problem of inability to product characterization and measurement, and inability to effectively monitor LDD doping process , LDD deviation and other issues to achieve the effect of improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further illustrate the technical means adopted by the present invention and its effects, a detailed description is given below in conjunction with the preferred embodiments of the present invention and the accompanying drawings.

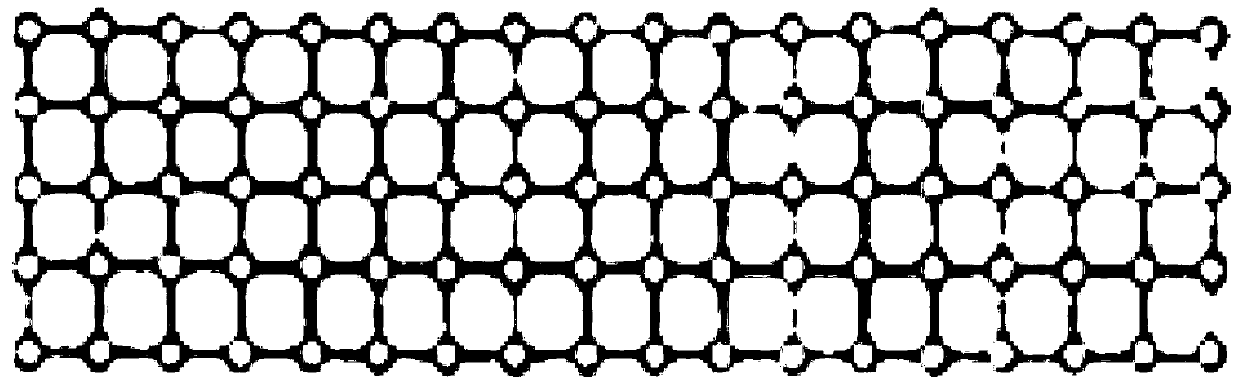

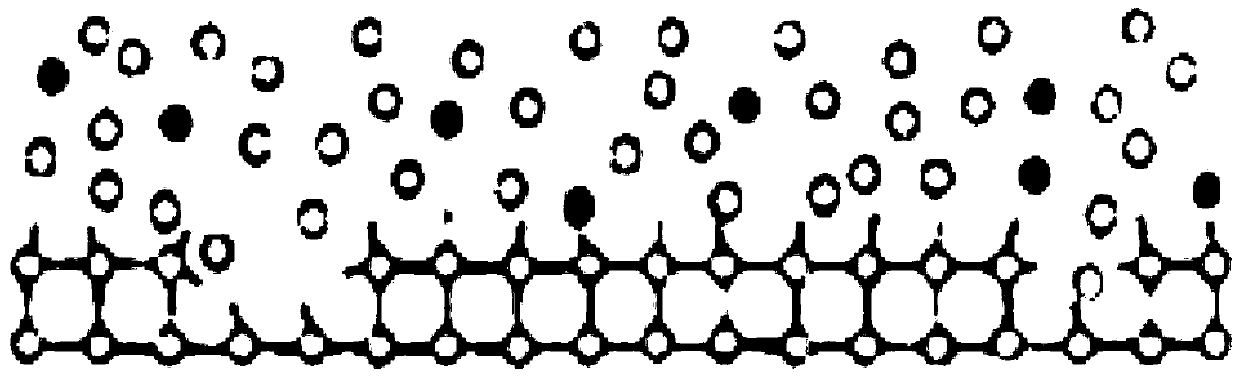

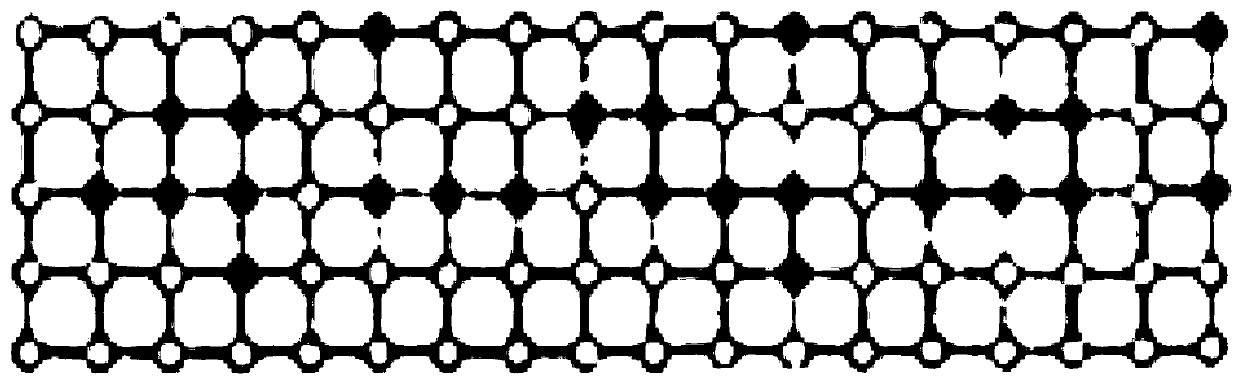

[0051] see figure 2 , the present invention first provides a method for making a test sample for measuring the length of a lightly doped drain region, including the following steps:

[0052] Step S1, such as image 3 As shown, a base substrate 1 is provided on which a cover buffer layer 2 is deposited.

[0053]The base substrate 1 is preferably a glass substrate; the material of the buffer layer 2 is silicon nitride (SiNx), silicon oxide (SiOx), or a combination of the two.

[0054] Step S2, such as Figure 4 As shown, an amorphous silicon layer is deposited on the buffer layer 2, the amorphous silicon layer is crystallized to obtain a polysilicon layer 3', and the polysilicon layer 3' is patterned.

[0055] In this step S2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com