Fabrication method of high-efficiency Q-LED package structure

A technology of packaging structure and manufacturing method, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as weak electroluminescence performance, Q-LED efficiency, life, processing technology and other comprehensive performance can not fully meet people's requirements and other problems , to achieve the effect of low production cost, ensuring light and color uniformity, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

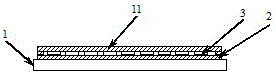

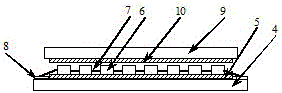

[0016] combine Figure 1-2 , the specific steps of this embodiment are: preparing quantum dot film layer: depositing a layer of parylene 2 on the substrate 1, arranging the quantum dot array 3 as required, coating the quantum dots on the substrate in turn, curing, and depositing again after curing One layer of parylene layer 11 seals the quantum dots between the two layers of parylene layers, and finally peels the film layer from the glass substrate to form the final quantum dot film layer; the transparent film coated with conductive metal electrodes at both ends The substrate 4 is coated with ultraviolet photosensitive adhesive, the quantum dot film layer 5 is cut into a suitable size according to the packaging requirements, and it is pasted on the substrate 4 with an automatic adhesive machine, and then cured; after the chip 6 is glued, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com