Flexible OLED display and manufacturing method thereof

A manufacturing method and display technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problem of affecting the packaging effect of flexible OLED displays, increasing light loss of flexible OLED displays, increasing edge stress of packaging structures, etc. problem, achieve the effect of improving the light extraction ability, reducing the water vapor transmission rate, and reducing the edge stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

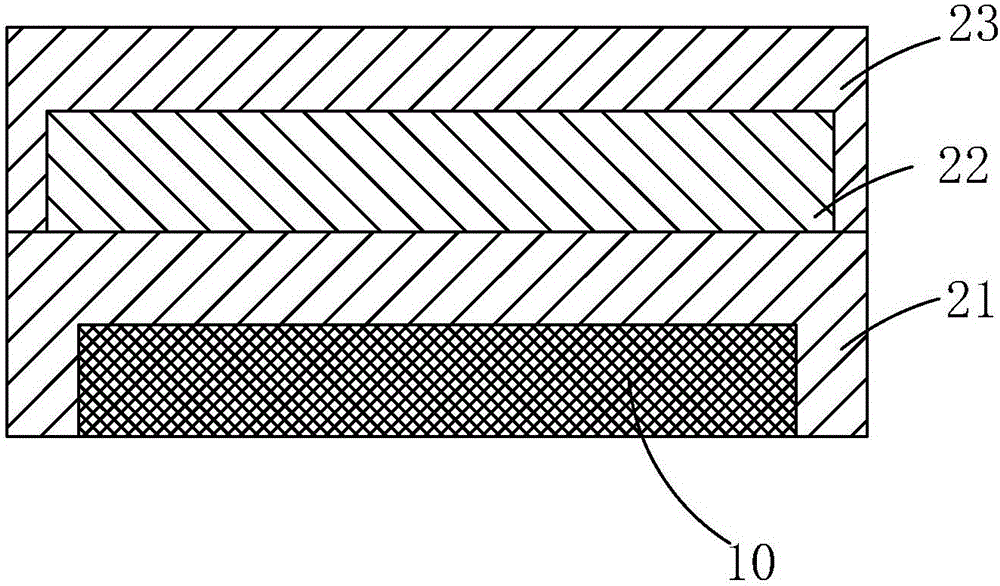

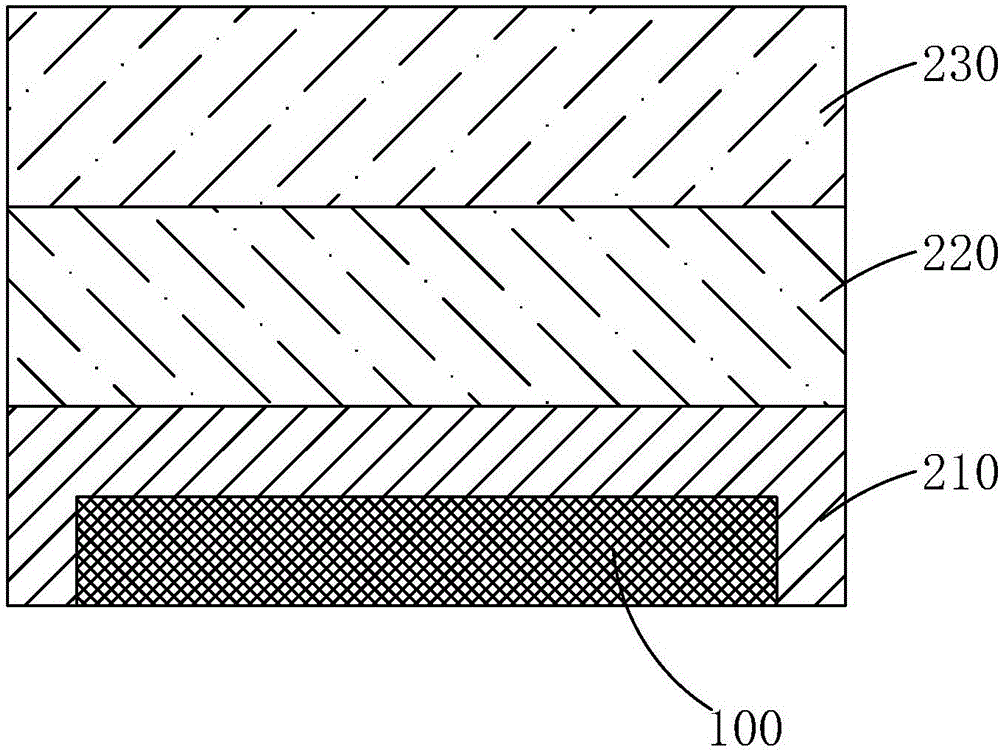

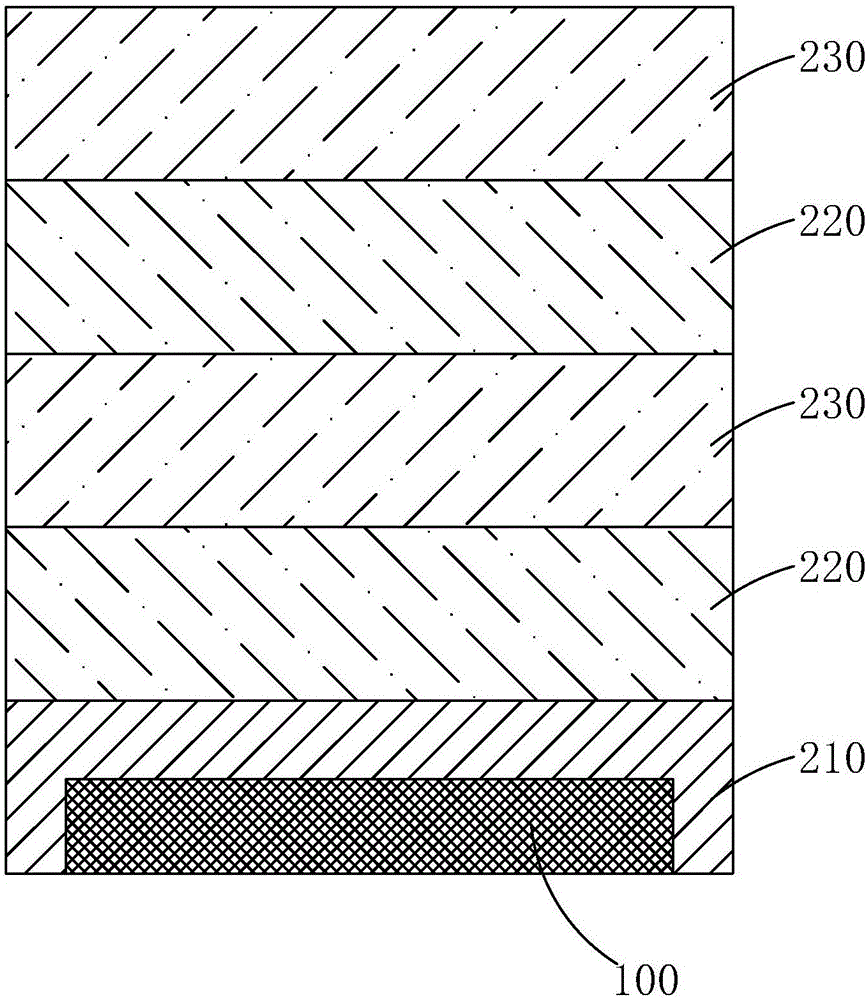

[0051] The present invention provides a flexible OLED display, please refer to figure 2 , is the first embodiment of the flexible OLED display of the present invention, including a flexible substrate (not shown), an OLED device 100 disposed on the flexible substrate, a barrier layer 210 covering the upper surface and side surfaces of the OLED device 100, A water-absorbing buffer layer 220 disposed on the barrier layer 210, and a light extraction enhancing buffer layer 230 disposed on the water-absorbing buffer layer 220;

[0052] The water-absorbing buffer layer 220 includes a first organic material and water-absorbing particles doped in the first organic material;

[0053] The light extraction enhancing buffer layer 230 includes a second organic material and refraction particles doped in the second organic material;

[0054] The size of the areas covered by the blocking layer 210 , the water-absorbing buffer layer 220 , and the light extraction enhancing buffer layer 230 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com