Method for efficiently and automatically clearing residual alkali solution after formation of zinc-silver battery pole piece

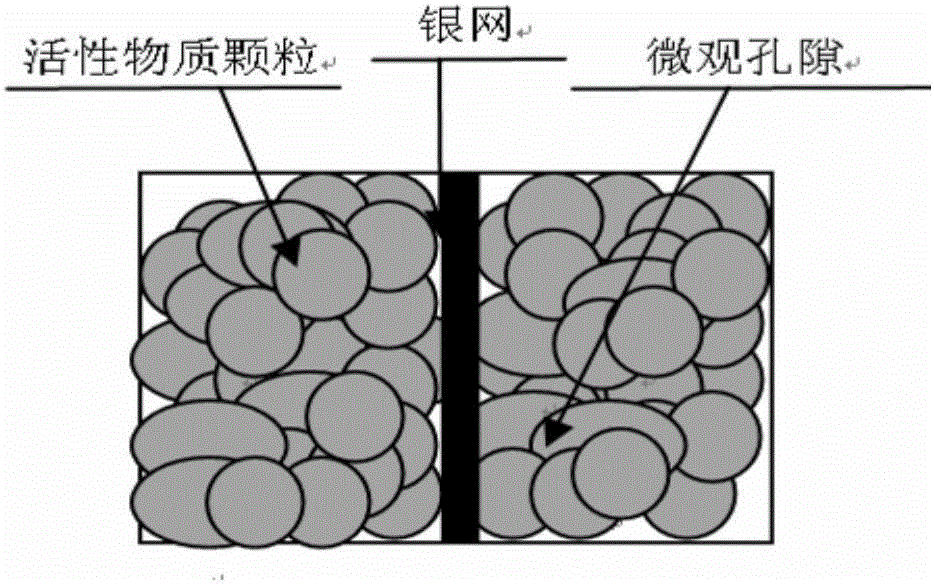

An automatic cleaning technology for zinc-silver batteries, which is applied in the manufacture of silver storage batteries, alkaline storage batteries, and alkaline storage batteries. The risk of residual alkaline solution corroding electrodes, reducing the amount of pure water used for cleaning, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

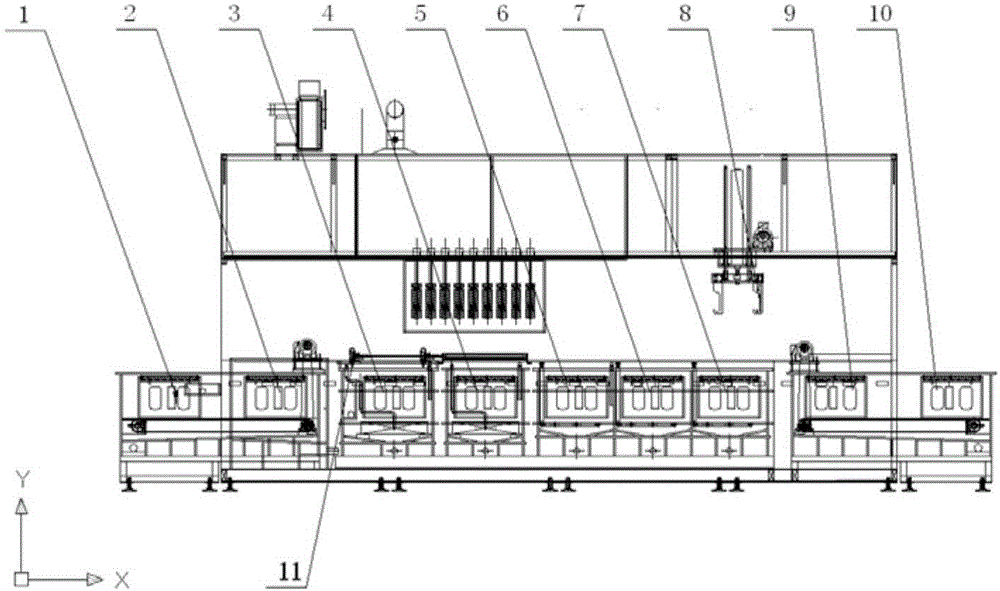

[0023] The system for efficiently and automatically removing residual lye from zinc-silver battery pole pieces of the present invention is shown in image 3 . The specific implementation instructions are as follows:

[0024] The pole piece to be cleaned is suspended in the cleaning basket and placed in the system station 1, the automatic cleaning process is started, the cleaning basket is sent to the station 2 by the chain transmission, and the mechanical arm 8 moves to the station and the cleaning basket is lifted vertically and sent to the station. Station 3 is lowered, and station 3 is equipped with a lateral reciprocating jet injection device to quickly rinse the surface of the suspended pole piece, taking away a large amount of KOH solution on the surface of the pole piece, and then station 3 automatically enters the cleaning solution and starts the configured ultrasonic device 1 (25kHz) for 3 minutes, using the cavitation effect of ultrasound to make the internal pores ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com