Hybrid optoelectronic encoder installation error compensation value determination system and method

A photoelectric encoder, installation error technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problem of affecting the accuracy of servo motor startup and operation control, the inability of the servo motor to start or reverse, and reducing the efficiency of the control system, etc. , to achieve the effect of easy popularization, simple structure and simplified implementation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

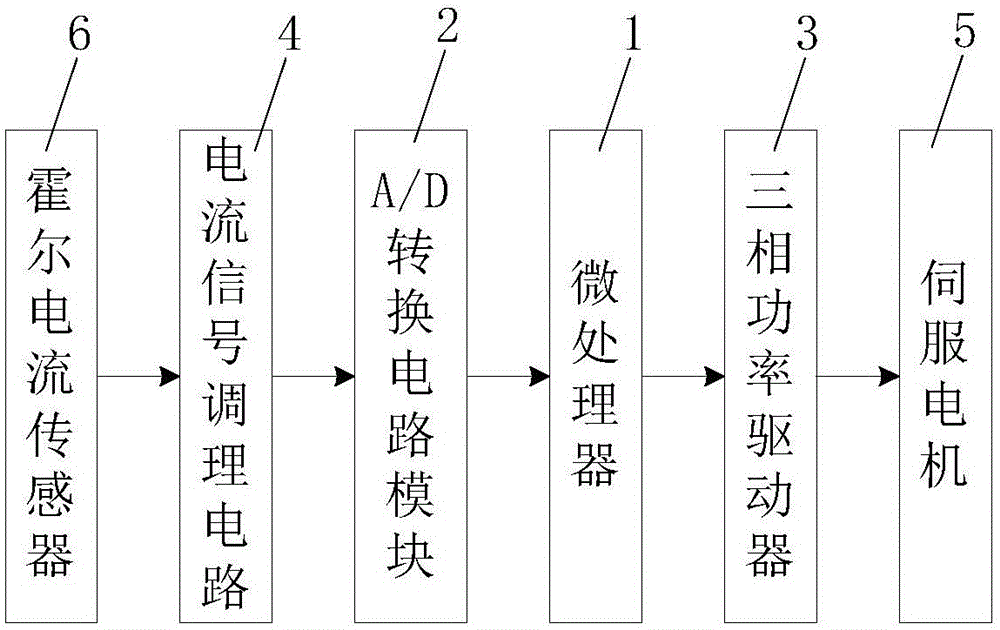

[0036] Such as figure 1 As shown, the hybrid photoelectric encoder installation error compensation value determination system of the present invention includes a microprocessor 1 and a Hall current sensor 6 for real-time detection of the DC bus current that supplies power to the servo motor 5. The microprocessor The input terminal of the device 1 is connected with an A / D conversion circuit module 2, and the input terminal of the A / D conversion circuit module 2 is connected with a current signal conditioning circuit 4 for amplifying and conditioning the signal output by the Hall current sensor 6, so The output terminal of the Hall current sensor 6 is connected with the input terminal of the current signal conditioning circuit 4, and the output terminal of the microprocessor 1 is connected with a three-phase power driver 3 for driving a servo motor 5 equipped with a hybrid photoelectric encoder , the servo motor 5 is connected to the output end of the three-phase power driver 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com