Bidirectional dual-helix permanent magnet brushless motor with torque adaptive speed change

A permanent magnet brushless motor, self-adaptive technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of inconvenient use, efficiency loss, high cost, etc., and achieve the effect of easy manufacturing, high reliability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

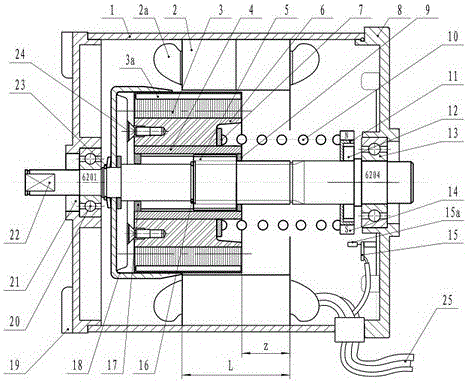

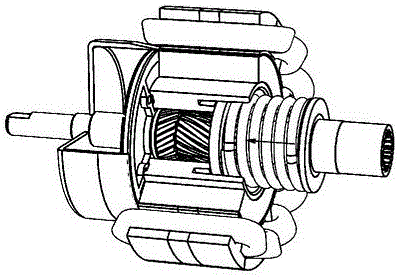

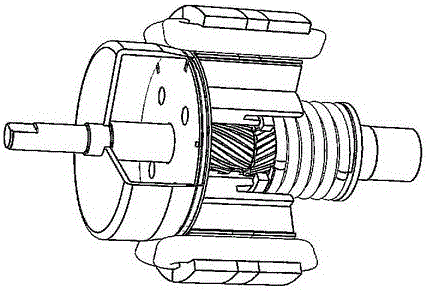

[0018] figure 1 It is one of the implementation cases of the present invention, and is used to illustrate the principle and process mechanism of shifting, and other 3D diagrams are specific design examples. It is not difficult for those skilled in the industry to understand according to this example and the existing basic professional knowledge, and based on this, an excellent permanent magnet brushless motor with torque adaptive variable speed effect can be produced.

[0019] Take the 2-fold speed change as an example to illustrate the field-weakening speed change. After reasonable simplification, the relevant parameters are defined as follows:

[0020] Motor rated rated voltage Ue, rated current Ie, rotor diameter D 2 , rotor length=L, average magnetic density Bδ, number of turns of stator winding N, rotor movement z, the speed ratio of this example is designed to be 2 times, according to the motor theory can be obtained

[0021] Air gap total magnetic flux Φ=D 2 *L* B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com